The rapid integration of robotics into industries has made maintenance technology a cornerstone of operational efficiency. In Heyuan, a city in Guangdong Province, China, advancements in robot repair and maintenance have positioned it as a hub for innovative solutions. This article explores the cutting-edge techniques, local expertise, and future prospects of robot maintenance technology in Heyuan.

1. The Rise of Robotics in Heyuan's Industrial Landscape

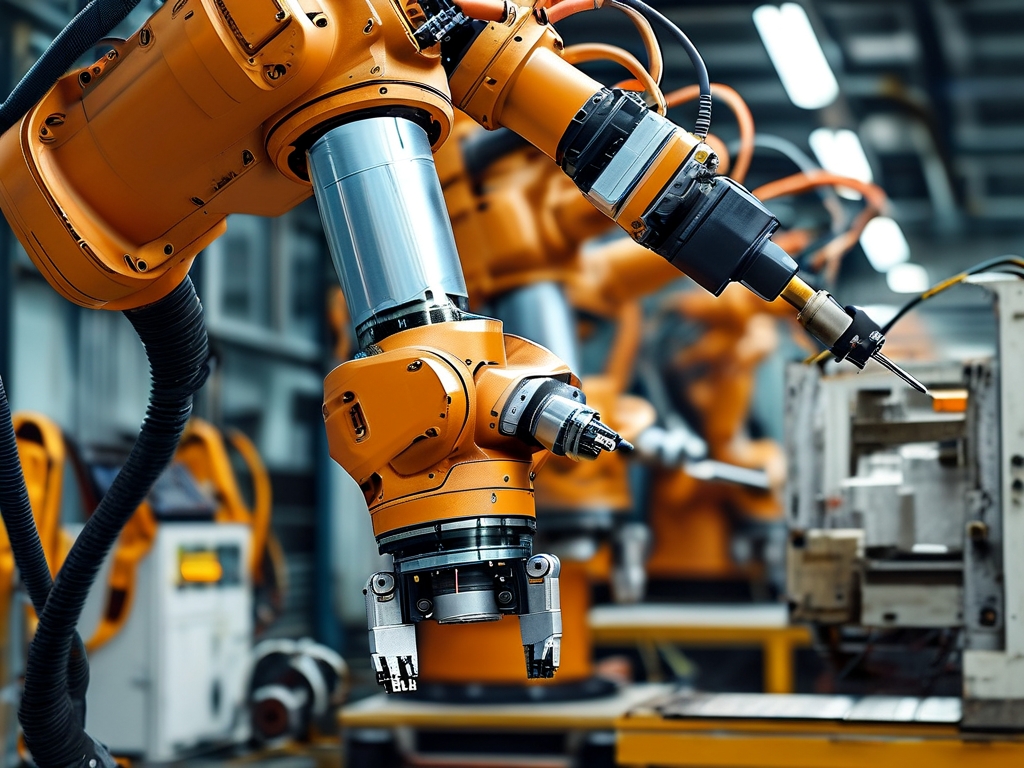

Heyuan's strategic location within the Greater Bay Area has fueled its transition toward high-tech industries. Over the past decade, the city has attracted robotics manufacturers specializing in automation for sectors like electronics, automotive assembly, and precision manufacturing. However, as robotic systems grow more complex, the demand for specialized maintenance has surged. Local technicians now focus on addressing challenges such as sensor calibration, hydraulic system failures, and AI-driven error diagnostics.

2. Core Technologies in Heyuan's Robot Maintenance

AI-Powered Diagnostic Systems

Heyuan's repair centers employ machine learning algorithms to predict equipment failures. By analyzing historical performance data, these systems identify patterns indicating wear and tear, enabling proactive maintenance. For instance, collaborative robots (cobots) used in assembly lines undergo real-time monitoring to prevent unexpected downtime.

Modular Repair Frameworks

To reduce repair time, technicians in Heyuan adopt modular replacement strategies. Instead of dismantling entire units, faulty components-such as servo motors or grippers-are swiftly swapped with pre-tested modules. This approach minimizes production interruptions and aligns with Industry 4.0 principles.

3D Printing for Custom Parts

Obsolete or customized robot parts often pose logistical challenges. Heyuan's workshops utilize 3D printing to manufacture replacement components on-site. For example, robotic arms with unique joint designs can be replicated using metal additive manufacturing, ensuring compatibility and reducing reliance on overseas suppliers.

3. Training and Skill Development

Heyuan's technical institutes collaborate with robotics firms to design certification programs. Trainees gain hands-on experience in:

- Circuit Board Repair: Diagnosing and soldering damaged circuits in control systems.

- Software Troubleshooting: Resetting embedded systems and debugging code errors.

- Safety Protocols: Adhering to ISO standards for human-robot interaction.

These programs emphasize adaptability, preparing technicians to work with diverse robotic brands, from Fanuc to ABB.

4. Case Studies: Success Stories from Heyuan

Automotive Manufacturing

A local electric vehicle factory reported a 40% reduction in downtime after adopting Heyuan's predictive maintenance model. Sensors embedded in welding robots now alert technicians to overheating risks 72 hours before failure.

Agricultural Automation

Heyuan's engineers developed a drone-repair toolkit for agricultural robots. By integrating thermal imaging, farmers can identify malfunctioning crop-monitoring drones and dispatch repair teams within hours.

5. Challenges and Innovations

Despite progress, obstacles remain. Aging industrial robots with proprietary software often resist third-party repairs. Heyuan's innovators are reverse-engineering legacy systems while advocating for "right-to-repair" policies. Additionally, the rise of quantum computing poses new demands for ultra-precise calibration tools.

6. The Future of Robot Maintenance in Heyuan

The city aims to become a global leader in sustainable repair practices. Research is underway to:

- Develop biodegradable lubrication fluids for robotic joints.

- Integrate 5G networks for remote diagnostics across international factories.

- Establish a robot "hospital" offering 24/7 repair services for critical industries.

Heyuan's robot maintenance technology exemplifies how regional expertise can drive global industrial resilience. By blending AI, modular design, and workforce training, the city not only sustains its own industries but also sets benchmarks for robotics ecosystems worldwide. As automation expands, Heyuan's commitment to innovation ensures it remains at the forefront of this transformative field.