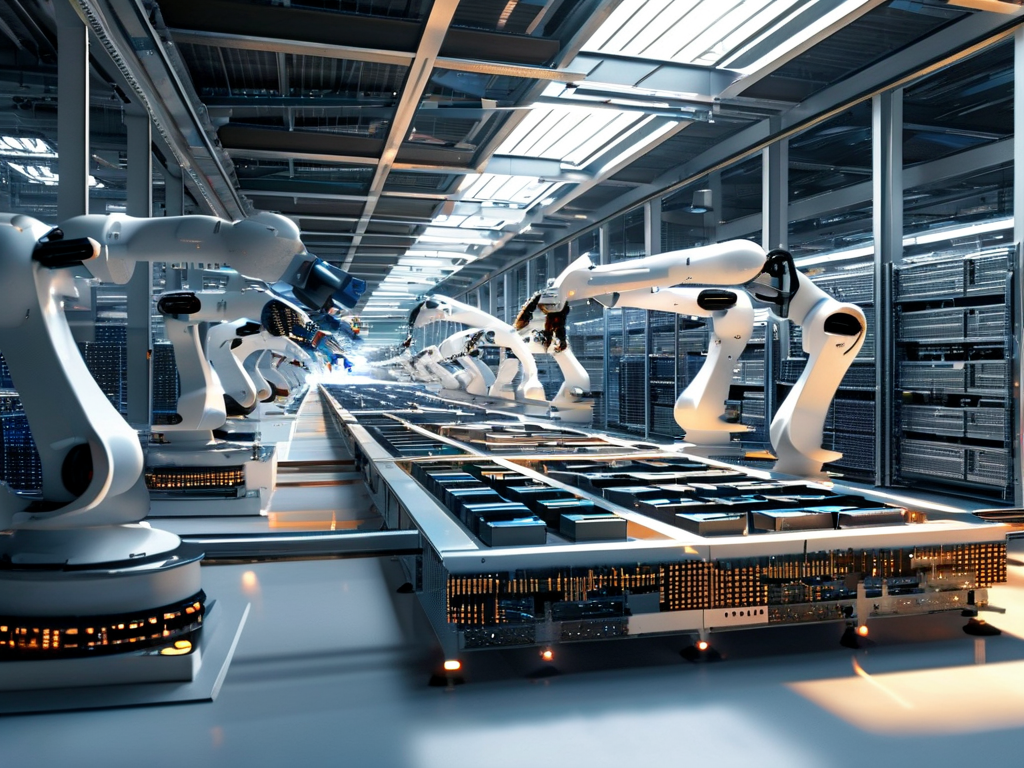

The integration of automated deployment in Manufacturing Execution Systems (MES) represents a transformative shift in modern industrial operations. As factories evolve toward smart manufacturing, automating MES workflows has become critical for maintaining competitiveness. This article explores how automated deployment methodologies enhance MES implementation while addressing practical challenges and future opportunities.

Foundations of MES Automation

At its core, MES bridges enterprise planning systems and factory-floor operations. Traditional MES deployments often involve weeks of manual configuration—a process prone to human error and version conflicts. Automated deployment introduces standardized templates and containerized solutions to streamline this workflow. For instance, tools like Kubernetes enable batch deployment of MES modules across distributed production lines, ensuring consistency in quality control and inventory management protocols.

Consider a pharmaceutical manufacturer implementing an MES upgrade. Through automated scripts, the company reduced deployment time from 28 days to 72 hours while maintaining compliance with FDA 21 CFR Part 11 regulations. Code snippets like the following demonstrate how environment variables can be configured dynamically:

apiVersion: apps/v1

kind: Deployment

metadata:

name: mes-batch-manager

spec:

template:

spec:

containers:

- name: mes-core

image: registry/mes:v4.2

env:

- name: PRODUCTION_LINE_ID

valueFrom:

configMapKeyRef:

name: plant-config

key: line_id

Operational Benefits and Challenges

Automated MES deployment delivers measurable ROI through reduced downtime and improved scalability. A 2023 study by the Manufacturing Leadership Council revealed that factories using automated deployment achieved 40% faster response to production anomalies compared to manual systems. However, challenges persist, particularly in legacy environments. Older PLCs and heterogeneous equipment often require custom adapters, as seen in automotive assembly lines where vintage robots lack modern API endpoints.

Cybersecurity remains another critical concern. While automation accelerates deployment, it also expands attack surfaces. Best practices include implementing encrypted deployment pipelines and zero-trust architectures. The recent NIST SP 800-82 revision specifically addresses securing automated MES workflows through hardware-based attestation and runtime protection.

Convergence with Emerging Technologies

The fusion of MES automation with IoT and digital twins is reshaping predictive maintenance strategies. Sensor data from CNC machines, when integrated with automated MES dashboards, enables real-time adjustments to production schedules. A case study from a German turbine manufacturer showed how automated OEE (Overall Equipment Effectiveness) calculations reduced unplanned downtime by 18% through machine learning-driven anomaly detection.

Looking ahead, the rise of edge computing introduces new deployment paradigms. Lightweight MES containers can now run directly on industrial gateways, processing data locally while syncing critical metrics to centralized systems. This hybrid approach balances latency requirements with cloud-based analytics capabilities.

Implementation Roadmap

Successful automated MES deployment requires phased execution:

- Infrastructure audit to identify automation-compatible assets

- Development of version-controlled deployment playbooks

- Gradual rollout with parallel manual oversight

- Continuous monitoring using tools like Prometheus for performance metrics

Vendor selection plays a pivotal role. Leading MES platforms like Siemens Opcenter and Rockwell FactoryTalk now offer native automation suites, while open-source alternatives like Apache PLC4X provide flexibility for custom integrations.

Future Perspectives

As 5G networks mature, the concept of "MES-as-a-Service" is gaining traction. Manufacturers could soon subscribe to fully automated MES instances tailored to specific production runs, complete with AI-driven optimization. The ongoing standardization of OPC UA over TSN (Time-Sensitive Networking) further supports this vision by enabling deterministic communication in automated deployments.

In , automating MES deployment is not merely a technical upgrade but a strategic imperative. By reducing implementation risks and accelerating time-to-value, manufacturers can focus on innovation rather than infrastructure management. As the industry progresses toward autonomous manufacturing, those who master MES automation today will lead tomorrow's smart factories.