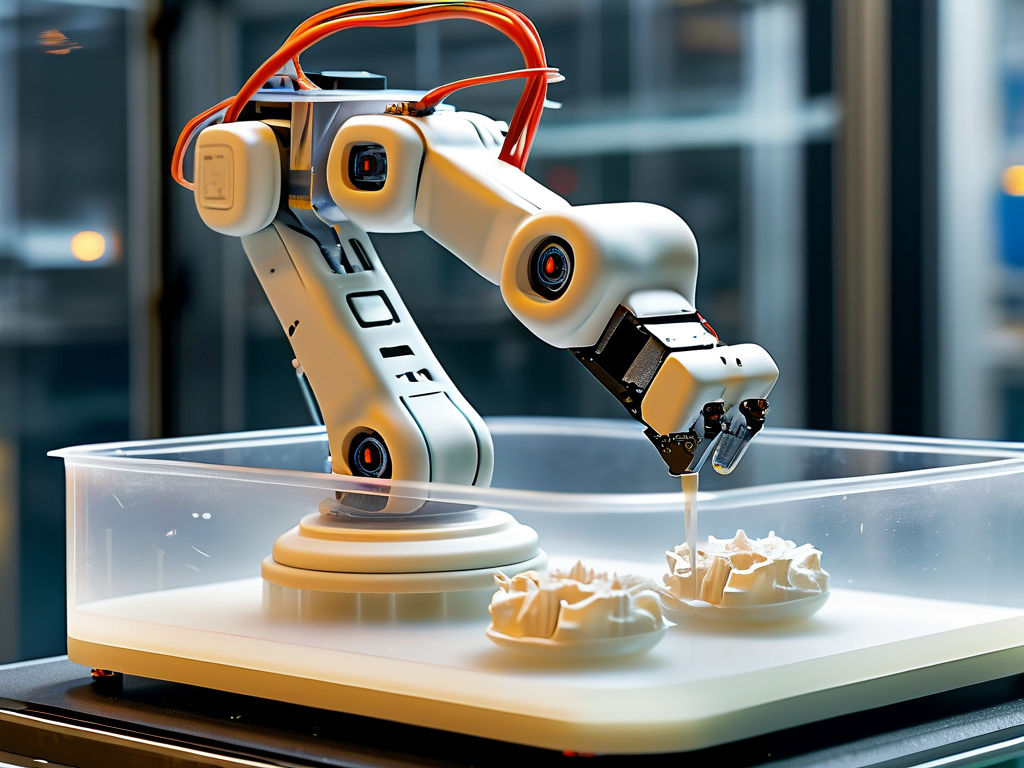

The intersection of soft robotics and additive manufacturing has sparked transformative innovations across industries. Unlike traditional rigid robots, soft robots leverage flexible materials to mimic biological movements, enabling unprecedented adaptability in complex environments. Recent breakthroughs in 3D printing techniques have accelerated the development of these systems, offering solutions to longstanding design and production challenges.

Material Innovation and Structural Precision

A key advantage of 3D printing lies in its ability to process elastomers, hydrogels, and shape-memory polymers—materials critical for soft robotic applications. For instance, researchers at Harvard’s Wyss Institute demonstrated a fully 3D-printed octopus-inspired gripper capable of handling fragile objects like raw eggs. By layering silicone-based inks with embedded pneumatic channels, the team achieved dynamic motion control without external hardware. This approach eliminates manual assembly steps, reducing production time by 60% compared to conventional methods.

Customization Through Hybrid Manufacturing

Multi-material printing now allows engineers to integrate rigid and soft components within a single fabrication cycle. A 2023 case study from MIT showcased a robotic prosthetic hand with gradient stiffness joints. The palm utilized stiff polymers for structural support, while finger joints employed thermoplastic polyurethane (TPU) for flexibility. Such hybrid designs enhance energy efficiency while maintaining load-bearing capacity—a balance previously unattainable through subtractive manufacturing.

Scalability Challenges and Solutions

Despite progress, scaling 3D-printed soft robotics remains hindered by material consistency and printing resolution. A study published in Nature Robotics revealed that variations in nozzle temperature (±5°C) could alter elastomer elasticity by up to 30%. To address this, companies like Festo have adopted closed-loop quality control systems combining real-time thermal imaging and machine learning. Their latest AHD (Adaptive Hybrid Deposition) printers automatically adjust parameters mid-print, achieving ±0.1mm dimensional accuracy across 1m-scale components.

Applications Redefining Industry Standards

- Medical Rehabilitation: Seoul National University Hospital deployed 3D-printed soft exoskeletons for stroke patients. The devices use dielectric elastomer actuators (DEAs) to provide adjustable assistance during gait training, improving recovery rates by 40% over rigid alternatives.

- Underwater Exploration: Monterey Bay Aquarium Research Institute (MBARI) developed a biohybrid robotic jellyfish with 3D-printed silicone bell structures. Propelled by ionic polymer-metal composites (IPMCs), it navigates marine ecosystems without disturbing delicate organisms.

Future Directions and Ethical Considerations

Emerging techniques like 4D printing—where printed structures evolve post-production—promise to revolutionize soft robotics further. However, the disposal of programmable materials raises environmental concerns. The European Union’s recent guidelines mandate lifecycle assessments for all polymer-based robotic components, pushing manufacturers toward biodegradable alternatives like cellulose-chitosan blends.

As 3D printing resolution approaches cellular scales (sub-10μm), ethical debates intensify regarding biohybrid systems. The 2024 Tokyo Protocol established global standards for integrating living tissues with printed soft robots, emphasizing transparency in biomedical applications.

In , 3D printing has evolved from a prototyping tool to the backbone of soft robotic manufacturing. By overcoming material and geometric constraints, this synergy is redefining what machines can achieve—from minimally invasive surgery to environmental monitoring. Yet, as the technology advances, balancing innovation with sustainability and ethical responsibility remains paramount.