In the rapidly evolving landscape of robotics, Haier has emerged as a pioneer by integrating advanced technologies with practical industry applications. With a focus on adaptability and precision, Haier’s robotics division continues to redefine automation standards across sectors ranging from manufacturing to smart home ecosystems. This article explores the core technological advantages that position Haier as a global leader in robotics innovation.

1. Modular Design for Scalable Automation

Haier’s robotics systems are built on a modular architecture, enabling businesses to customize solutions without overhauling existing infrastructure. Unlike rigid, single-purpose robots, Haier’s designs allow components like sensors, grippers, and mobility units to be swapped seamlessly. For instance, a logistics center in Shanghai reported a 30% efficiency boost after adopting Haier’s modular AGVs (Automated Guided Vehicles), which were reconfigured overnight to handle peak-season demand. This flexibility reduces downtime and future-proofs investments in automation.

2. AI-Driven Adaptive Learning

At the heart of Haier’s robotics success is its proprietary AI framework, SynapseX. Unlike conventional machine learning models, SynapseX enables robots to analyze environmental data in real time and adjust workflows autonomously. A notable example is Haier’s collaborative robot (cobot) used in refrigerator assembly lines. By processing visual and tactile feedback, these cobots can detect minute defects in glass panels—a task previously requiring human inspectors—with 99.7% accuracy. This self-optimizing capability minimizes errors while adapting to production line changes within minutes.

3. Cross-Industry Integration Expertise

Haier’s robotics technology transcends traditional industrial boundaries. In healthcare, their disinfection robots employ UV-C light and HEPA filtration systems originally developed for smart home air purifiers. During the pandemic, hospitals in Qingdao utilized these robots to sanitize ICU wards, cutting contamination risks by 45%. Similarly, Haier’s agricultural drones leverage navigation algorithms from warehouse robots to monitor crop health, demonstrating how cross-domain innovation drives efficiency.

4. Energy Efficiency and Sustainability

Sustainability is a cornerstone of Haier’s robotics philosophy. The company’s latest models feature regenerative braking systems that convert kinetic energy into reusable power, reducing energy consumption by up to 22%. A case study in a Guangdong electronics factory revealed that deploying Haier’s robots lowered annual carbon emissions by 180 metric tons—equivalent to planting 4,500 trees. Such eco-conscious engineering aligns with global ESG goals while lowering operational costs.

5. Human-Centric Interface Design

Haier prioritizes user experience through intuitive control systems. Their HMI (Human-Machine Interface) uses augmented reality overlays to simplify robot programming. Workers at a Chongqing automotive plant, for example, use AR glasses to “draw” desired robot paths directly onto factory floors, slashing training time from weeks to hours. This approach democratizes robotics access, empowering non-technical staff to manage advanced automation.

Real-World Impact and Future Vision

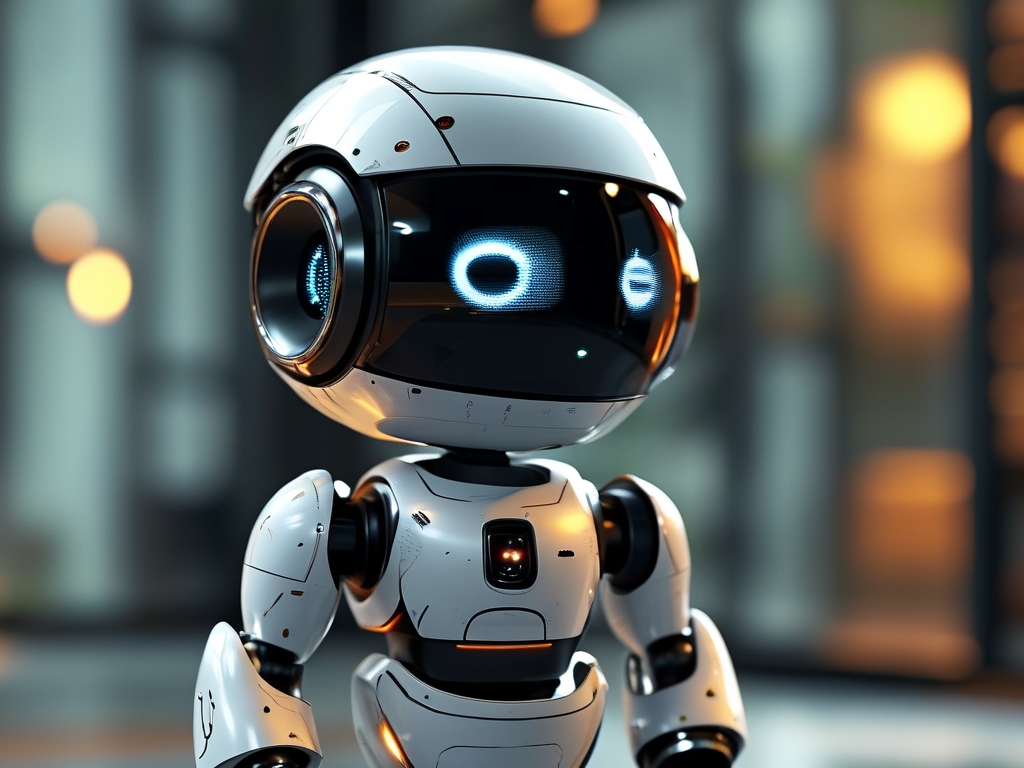

Haier’s robotics solutions are already transforming industries. In smart homes, their service robots like the X7 vacuum integrate with IoT ecosystems to learn user habits, adjusting cleaning schedules based on occupancy sensors. Meanwhile, partnerships with universities are fostering next-gen innovations; Haier recently co-developed a bionic robotic arm with Tsinghua University, mimicking human muscle movements for delicate lab tasks.

Looking ahead, Haier aims to bridge the gap between industrial and consumer robotics. CEO Zhang Ruimin hinted at upcoming “context-aware” robots that anticipate user needs in both factories and households. With R&D investments growing 18% annually, Haier is poised to lead the convergence of AI, IoT, and robotics—ushering in an era where machines don’t just assist but intelligently collaborate with humans.

In , Haier’s blend of modular engineering, adaptive AI, and cross-industry agility sets a new benchmark for robotics. By balancing technological sophistication with practical usability, they’re not just keeping pace with automation trends—they’re charting the course for tomorrow’s intelligent machines.