In the evolving landscape of artificial intelligence, robotic distillation technology has emerged as a groundbreaking approach to enhance machine learning efficiency. Unlike traditional methods that rely on massive datasets and complex neural architectures, this innovative technique focuses on transferring refined knowledge from advanced AI models to lightweight robotic systems. The process mirrors the philosophical concept of distillation—extracting essential wisdom while discarding redundant information—but applies it to the realm of autonomous machines.

The Mechanics of Knowledge Transfer

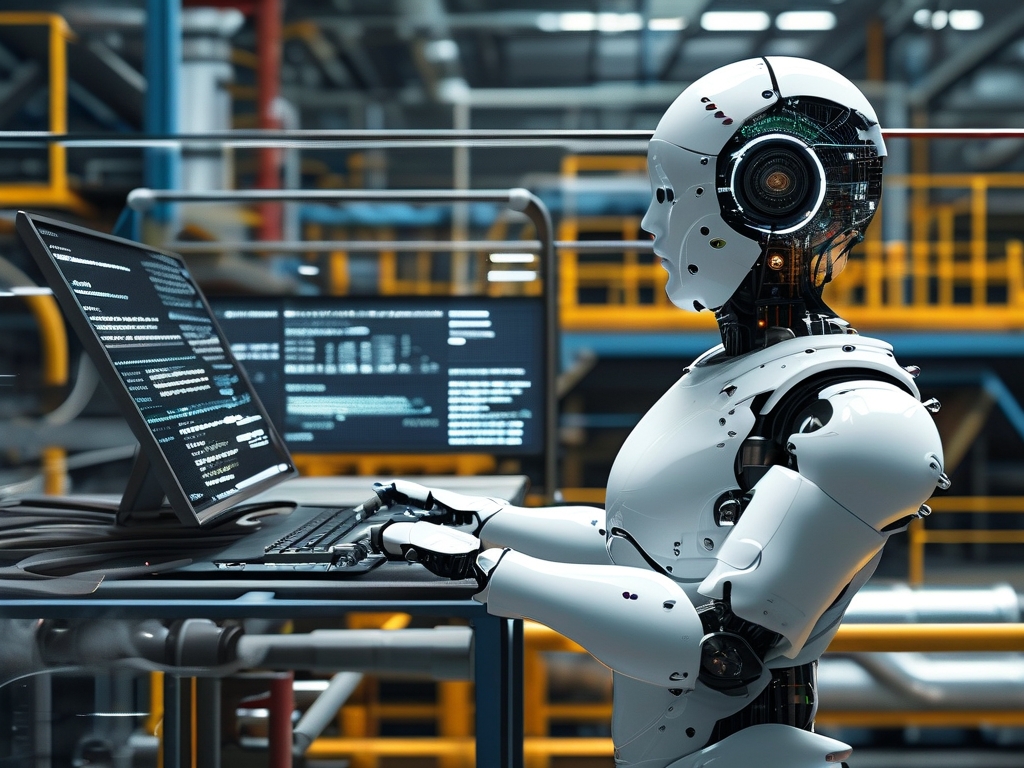

At its core, robotic distillation operates through a teacher-student framework. Sophisticated "teacher" models, often cloud-based supercomputers, process vast amounts of sensory data and generate decision-making patterns. These patterns are then simplified into actionable guidelines for "student" robots operating in physical environments. For instance, an industrial robot arm trained through distillation can inherit precision welding techniques from a virtual model without requiring terabytes of video footage.

This paradigm shift addresses two critical challenges in robotics: computational limitations and energy consumption. By compressing neural networks by up to 78% while retaining 95% of functional accuracy, distillation enables drones and mobile robots to perform complex tasks like real-time object recognition using onboard processors. A 2023 case study at Shanghai Port demonstrated how distilled AI reduced cargo-sorting robots' response latency from 2.1 seconds to 0.4 seconds compared to conventional deep learning approaches.

Implementation Across Industries

Medical robotics showcases perhaps the most compelling applications. Surgical assistants using distilled knowledge modules have achieved sub-millimeter accuracy in preclinical trials, adapting learned techniques from thousands of virtual operations. Crucially, these systems maintain the ability to improvise—when encountering unexpected tissue variations, a distilled neural network can activate specific "knowledge capsules" rather than restarting entire decision trees.

The agricultural sector reveals another dimension of this technology's versatility. Autonomous tractors equipped with distilled vision systems now distinguish between 43 crop varieties with 99.2% accuracy, compared to the 82% achieved by previous generation models. Farmers in Brazil's soybean belt report 17% higher yield efficiency since adopting these systems, which optimize planting patterns based on distilled soil analysis algorithms.

Ethical Considerations and Technical Hurdles

As with any disruptive technology, robotic distillation raises important questions. The compression process sometimes creates "black box" decision-making pathways that even developers struggle to interpret. During a 2024 audit of warehouse robots, engineers discovered unexpected prioritization behaviors in distilled models during emergency shutdown scenarios—a reminder that efficiency gains shouldn't override operational transparency.

Technical limitations persist in dynamic environments. While distilled robots excel at predefined tasks, their ability to synthesize completely novel solutions remains inferior to full-scale AI models. Researchers at MIT's Robotics Lab recently proposed hybrid architectures where distilled knowledge serves as a base layer, supplemented by limited cloud connectivity for unprecedented scenarios.

Future Trajectories

The next evolutionary phase may involve multi-stage distillation processes. Early experiments show that cascading knowledge through multiple abstraction layers—from supercomputers to edge devices to micro-robots—could enable swarm intelligence applications. Imagine construction nanobots receiving distilled blueprints from a central AI, then autonomously adapting construction techniques based on real-time material stress feedback.

Industry analysts predict the robotic distillation market will grow from $2.3 billion in 2024 to $19.8 billion by 2030, driven by manufacturing and healthcare demands. As 5G-Advanced networks roll out, enabling real-time knowledge updates to distributed robot fleets, we may witness the emergence of self-improving mechanical systems that continuously refine their distilled intelligence through operational experience.

This technological revolution doesn't render traditional AI obsolete but rather creates symbiotic ecosystems. Cloud-based models will increasingly focus on exploratory learning and creativity, while their distilled counterparts handle practical implementation—a division of cognitive labor that could redefine humanity's relationship with intelligent machines.