Modern engineering systems increasingly rely on electrically distributed control architectures to manage complex operations across industries like automotive manufacturing, industrial automation, and smart grid technologies. This article explores the fundamental design principles, operational advantages, and real-world applications of this innovative framework.

Core Design Philosophy

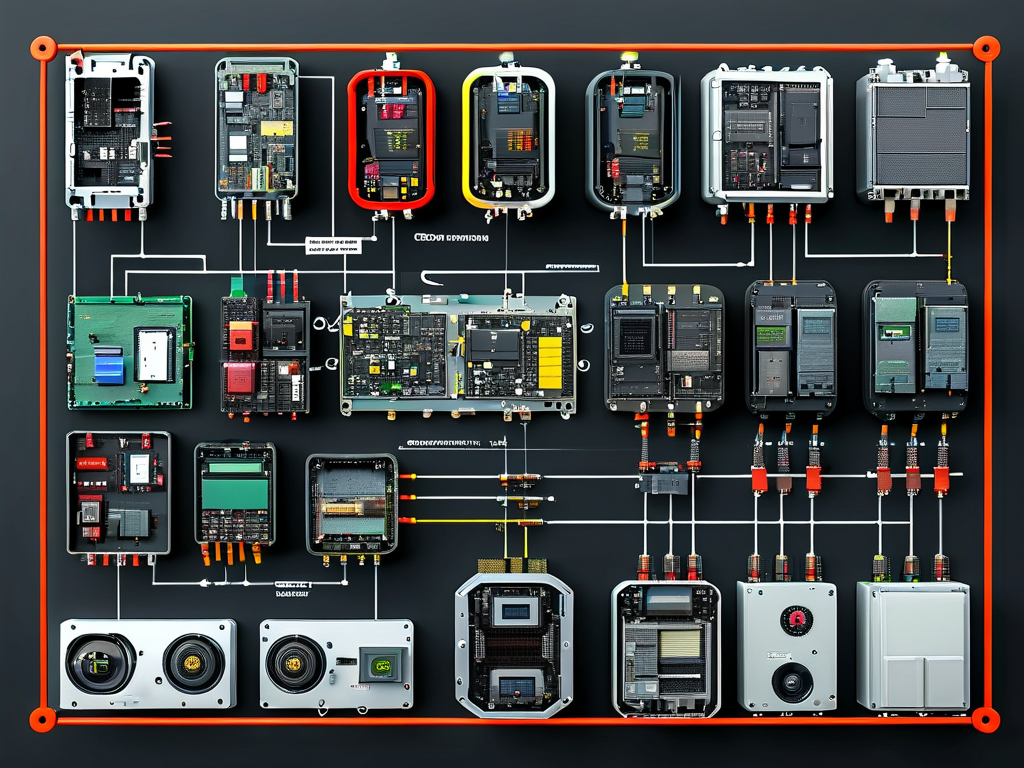

A distributed electronic control system decentralizes decision-making by assigning dedicated electronic control units (ECUs) to specific subsystems. Unlike traditional centralized systems, where a single controller handles all tasks, this architecture delegates responsibilities. For example, in electric vehicles (EVs), separate ECUs manage battery thermal regulation, motor torque distribution, and regenerative braking. These units communicate via high-speed networks like CAN (Controller Area Network) or Ethernet protocols, ensuring synchronized operation without overloading a central processor.

A typical implementation involves:

// Example of ECU communication logic

void manageMotorTorque() {

int sensorData = readWheelSpeed();

adjustTorque(sensorData);

broadcastToNetwork("TORQUE_ADJUSTED");

}

This code snippet illustrates how localized processing reduces latency by minimizing data routing to a central hub.

Operational Advantages

- Fault Tolerance: Isolated ECUs ensure subsystem failures don’t cascade. If an EV’s infotainment ECU malfunctions, it won’t affect critical drivetrain controls.

- Scalability: Adding new components—like a lidar sensor to an autonomous vehicle—requires only integrating a new ECU rather than redesigning the entire system.

- Real-Time Responsiveness: Distributed processing slashes decision-making delays. Industrial robots using this architecture achieve microsecond-level precision in assembly tasks.

Automakers like Tesla and BMW have adopted this approach to streamline over-the-air (OTA) updates. Instead of rewriting an entire vehicle’s software, updates target specific ECUs. For instance, a brake calibration patch only interacts with the braking subsystem’s controller.

Industry Applications

- Automotive: Modern cars contain 70-100 ECUs managing everything from engine timing to adaptive cruise control. Distributed architectures enable features like predictive collision avoidance by allowing radar, camera, and steering ECUs to collaborate seamlessly.

- Smart Grids: Power distribution networks use decentralized controllers to balance loads, reroute electricity during outages, and integrate renewable energy sources.

- Aerospace: Airbus’s A350 employs over 6,000 distributed modules to monitor wing flex, cabin pressure, and engine performance in real time.

Challenges and Solutions

While distributed systems reduce single-point failures, they introduce complexity in synchronization and security. Cross-ECU communication demands rigorous timing protocols. Engineers address this using time-triggered architectures (TTA), where actions execute at predefined intervals. For cybersecurity, hardware-level encryption modules like HSM (Hardware Security Modules) protect data exchanges between controllers.

A practical challenge emerged during the development of GM’s Ultium EV platform: ensuring battery management ECUs from different suppliers adhered to uniform communication standards. The solution involved creating a middleware layer to translate proprietary protocols into a universal format.

Future Directions

The rise of edge computing and 5G connectivity will further enhance distributed systems. In agriculture, John Deere’s autonomous tractors use edge-based ECUs to process field data locally while transmitting only essential analytics to cloud servers. Similarly, smart cities are adopting distributed traffic control systems where intersection-specific ECUs adjust signal timings based on real-time pedestrian and vehicle flow.

Researchers are also exploring AI-driven ECUs capable of adaptive learning. NVIDIA’s DRIVE platform, for instance, allows autonomous vehicle controllers to refine object recognition algorithms based on regional driving patterns without central server dependency.

Distributed electronic control architectures represent a paradigm shift in system design, balancing robustness with flexibility. By understanding their structure and leveraging emerging technologies like edge computing and adaptive AI, industries can build smarter, safer, and more efficient systems. As demonstrated by advancements in EVs, industrial automation, and infrastructure management, this framework is poised to redefine technological innovation across sectors.