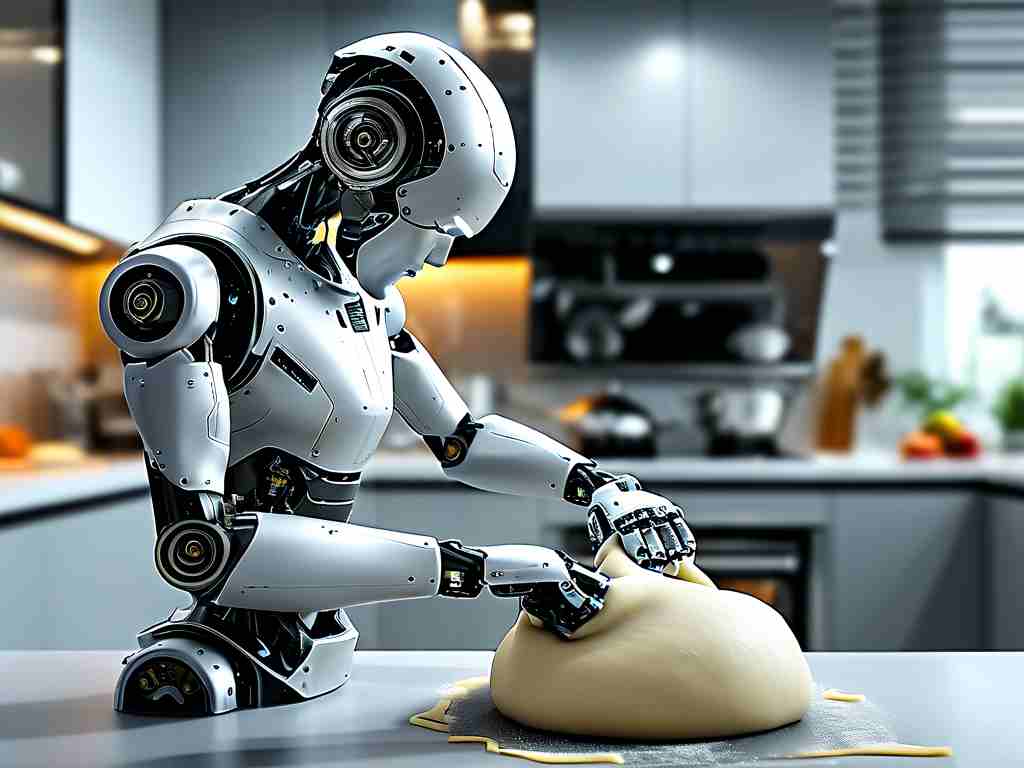

In the evolving landscape of food production, robotic dough kneading technology has emerged as a game-changer for bakeries and industrial kitchens. By combining mechanical engineering with advanced algorithms, this innovation addresses longstanding challenges in consistency, labor costs, and hygiene. Let’s explore how these systems work and why they’re reshaping the future of baking.

Core Mechanics of Robotic Kneading

At the heart of robotic dough kneading lies a multi-axis robotic arm equipped with specialized attachments. Unlike human hands, these tools apply programmable pressure patterns calibrated to specific dough types. For instance, a high-gluten bread dough requires rhythmic compression-and-stretch cycles, while pastry dough demands gentler folding motions. Sensors embedded in the system monitor real-time variables like temperature, viscosity, and elasticity, adjusting torque and speed through closed-loop feedback mechanisms.

A key component is the torque-controlled motor, which mimics the "feel" of human kneading. By analyzing resistance data from the dough mass, the robot dynamically modifies its movements to prevent overworking or underprocessing. This is particularly critical for artisanal products where texture defines quality.

Algorithmic Intelligence in Action

Behind the physical hardware lies proprietary software that converts culinary expertise into mathematical models. Machine learning algorithms trained on thousands of dough samples can predict optimal kneading durations. For example, a sourdough starter with 78% hydration might trigger a 12-minute knead cycle with intermittent rest periods, replicating techniques used by master bakers.

Some systems integrate computer vision to assess dough development stages. Cameras track surface glossiness and air bubble distribution – visual cues that traditionally require human judgment. When the software detects the desired "windowpane effect" (where stretched dough becomes translucent without tearing), it automatically halts the process.

Hygiene and Scalability Advantages

Traditional kneading poses contamination risks from human contact, especially in large-scale operations. Robotic systems, constructed with food-grade stainless steel and sealed joints, minimize microbial growth areas. Automated self-cleaning protocols using steam or UV light further enhance food safety compliance.

From a production standpoint, these robots achieve what manual labor cannot: uninterrupted 24/7 operation. A single unit can process 300 kg of dough per hour with ±1.5% weight consistency – crucial for industrial packaging standards. Bakeries report 40-60% reductions in waste due to precise ingredient measurement and mixing.

Challenges and Adaptability

Despite their sophistication, early-generation kneading robots struggled with variable raw materials. Flour protein content fluctuations or ambient humidity changes could disrupt outcomes. Newer models address this through adaptive learning. If a batch absorbs water unusually fast, the system logs this anomaly and compensates in subsequent cycles.

Another breakthrough involves hybrid systems that combine robotics with traditional methods. In Japan, some bakeries deploy robots for initial mixing before transferring dough to human artisans for final shaping – a balance of efficiency and craftsmanship.

Economic and Environmental Impact

While the upfront cost of a dough-kneading robot ranges from $50,000 to $120,000, ROI typically materializes within 18 months through labor savings and yield optimization. Energy consumption is another focus area; latest models use regenerative drives that recover kinetic energy during deceleration, cutting power usage by 22% compared to 2020 versions.

From an environmental perspective, precision kneading reduces water and flour waste. A 2023 case study at a European bakery showed a 17-ton annual reduction in flour consumption after adopting robotic systems, equivalent to saving 4 hectares of wheat farmland.

Future Directions

Emerging trends include IoT-enabled kneading robots that sync with ovens for end-to-end production control. Researchers are also experimenting with 3D-printed dough structures impossible to achieve manually. Looking ahead, as artificial intelligence becomes more nuanced in understanding regional baking traditions – from San Francisco sourdough to Indian naan – robotic kneading could paradoxically become a tool for preserving culinary heritage amid industrialization.

In , robotic dough kneading technology isn’t about replacing bakers but augmenting their capabilities. By handling repetitive tasks with machine precision, it allows human creativity to flourish in recipe development and quality innovation – a recipe for sustainable growth in the food industry.