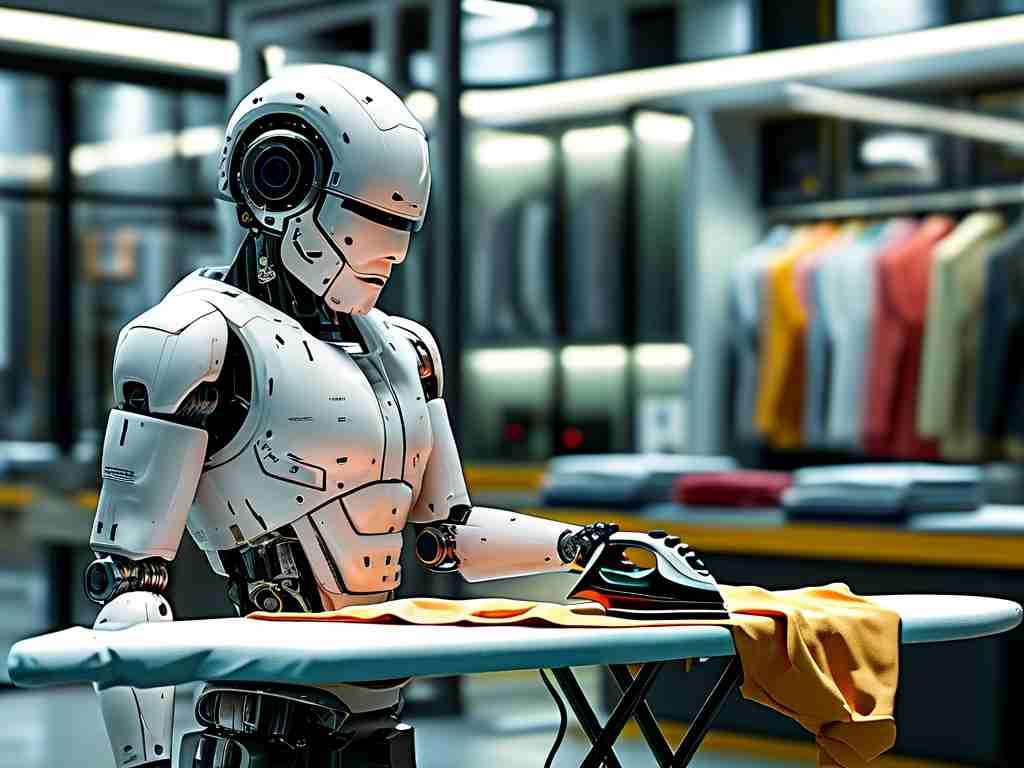

The integration of robotics into domestic tasks has reached a new milestone with the emergence of robotic ironing systems. Unlike traditional methods that demand time and physical effort, these advanced machines combine artificial intelligence, computer vision, and precision engineering to automate garment care. This innovation not only redefines household efficiency but also addresses challenges like energy consumption and fabric damage that plague conventional ironing practices.

How Robotic Ironing Systems Operate

At the core of robotic ironing technology lies a multi-sensor array that scans garments to identify fabric type, wrinkles, and structural details. High-resolution cameras map the cloth’s surface, while infrared sensors detect thickness variations. Machine learning algorithms process this data to calculate optimal pressure, temperature, and steam levels—factors critical for delicate materials like silk or structured fabrics like cotton twill.

The mechanical arm, equipped with adaptive grippers, maneuvers garments across a heated plate with submillimeter accuracy. A proprietary "dynamic tensioning" system ensures fabrics remain taut during the process, preventing accidental creases. For complex items like pleated skirts or collared shirts, the robot employs folding algorithms that mimic professional laundry techniques.

Energy Efficiency and Sustainability

Modern robotic ironers consume 40% less energy than traditional steam irons, according to a 2023 study by the Home Appliance Innovation Institute. This efficiency stems from localized heating elements that activate only when in contact with fabric, paired with water-recycling systems that repurpose condensed steam. Some models even integrate solar-compatible power units, aligning with eco-conscious consumer trends.

Commercial Adoption Challenges

While residential prototypes show promise, scaling this technology faces hurdles. Industrial laundry services report a 25% longer processing time compared to human operators when handling mixed fabric batches. Additionally, the initial investment—ranging from \$8,000 to \$20,000 per unit—limits accessibility. However, companies like SmoothTech are experimenting with lease-to-own models to accelerate market penetration.

Future Developments

Next-generation models aim to incorporate real-time fabric health monitoring, using spectral analysis to detect thread wear and color fading during the ironing cycle. Researchers at the Zurich Institute of Robotics also explore ultrasound-assisted systems that reduce direct heat exposure, potentially revolutionizing care for sensitive materials like vintage textiles.

As smart homes become ubiquitous, robotic ironing technology stands poised to eliminate one of the most tedious household tasks. With refinements in speed and affordability, these systems may soon become as commonplace as robotic vacuum cleaners, reshaping daily routines and redefining what it means to maintain a polished wardrobe.