The integration of robotics into the food service industry has revolutionized how restaurants and hospitality businesses operate. Among these innovations, robotic food delivery systems stand out for their ability to enhance efficiency, reduce human error, and create unique dining experiences. This article delves into the core technologies powering robotic food service, their practical applications, and the challenges shaping their future adoption.

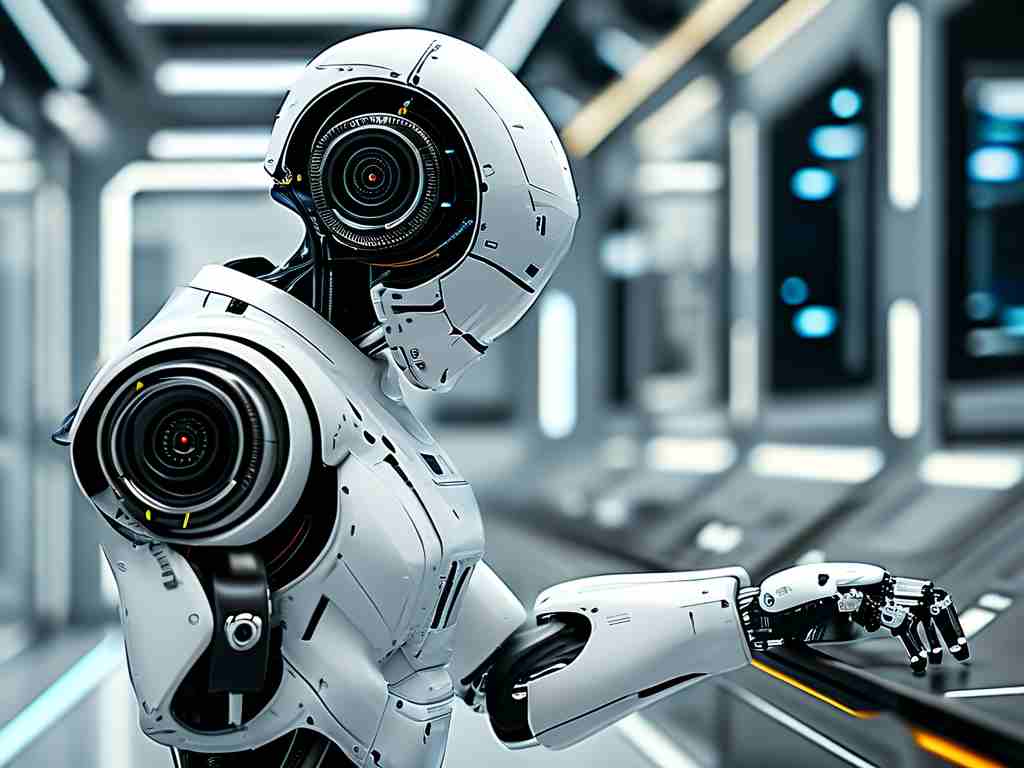

Sensing and Navigation: The Foundation of Precision

At the heart of robotic food service lies advanced sensing and navigation technology. Most systems rely on a combination of LiDAR (Light Detection and Ranging) and infrared sensors to map environments in real time. For instance, the AICook-Serve model by TechDine uses 360-degree LiDAR arrays to detect obstacles as small as 5 centimeters, ensuring smooth navigation in crowded dining spaces. Simultaneous Localization and Mapping (SLAM) algorithms enable robots to adjust paths dynamically, even when patrons unexpectedly move chairs or stand in walkways.

To maintain stability during transport, inertial measurement units (IMUs) continuously monitor acceleration and tilt. This is critical when handling liquids or delicate presentations—a spilled soup bowl could mean more than just a technical failure; it risks customer satisfaction.

Gripping Mechanisms: Balancing Flexibility and Safety

Unlike industrial robotic arms designed for repetitive tasks, food service robots require adaptable gripping systems. Vacuum-based suction cups dominate for handling standardized plates, while multi-fingered pneumatic grippers manage irregularly shaped items like cocktail glasses. The GRIP-5X module, for example, employs pressure-sensitive silicone pads that adjust grip strength based on object weight detection, preventing damage to fragile tableware.

However, challenges persist. A 2023 study by the Robotics in Hospitality Institute found that 12% of food-serving robots struggled with ultra-smooth surfaces like polished ceramic bowls. Innovations such as micro-textured grip surfaces and electrostatic adhesion are now being tested to address these limitations.

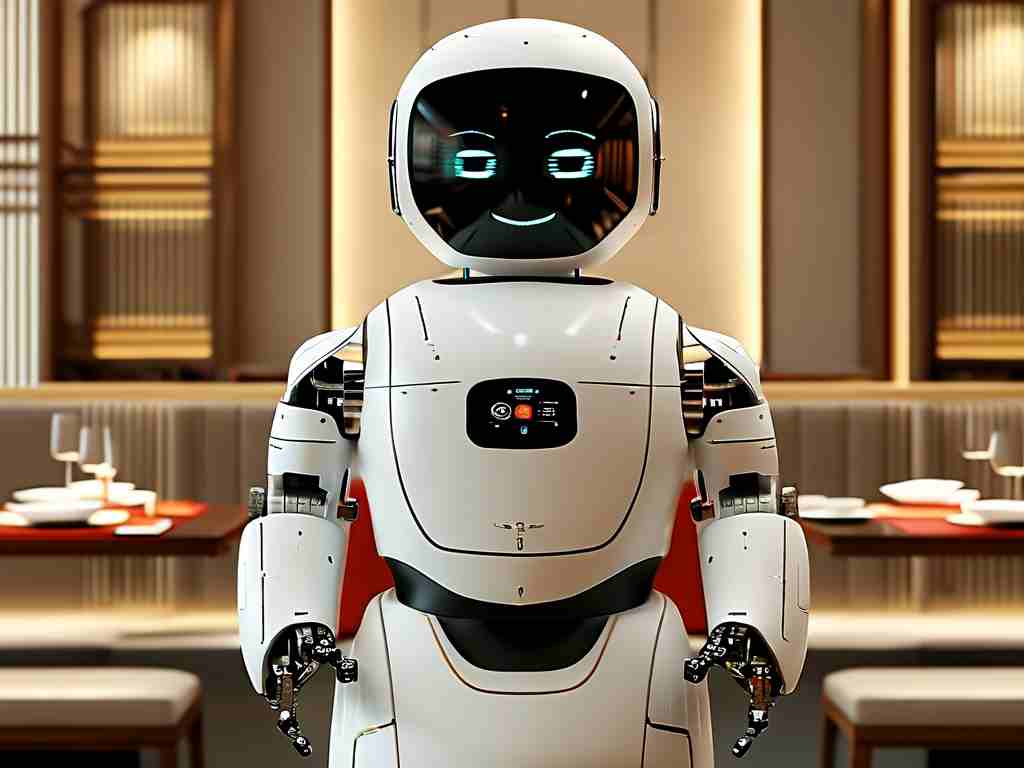

Human-Robot Interaction: Bridging the Experience Gap

Successful deployment requires seamless interaction between robots and humans. Voice recognition systems like ServeBot’s “VocalSync” allow customers to issue simple commands (“Pause here” or “Return to kitchen”), while LED facial displays convey operational status through emotive icons. Privacy concerns, however, have prompted strict data encryption protocols for any audio recordings.

In upscale Tokyo restaurant NanoEats, robots incorporate basic gesture recognition. Patrons can wave twice to signal approval for a dish to be placed on the table, adding a layer of intuitive control. These features aim to preserve the human touch in dining while leveraging robotic precision.

Energy and Maintenance: The Hidden Costs

While robots reduce labor expenses, their operational logistics require careful planning. Most food service robots operate on lithium iron phosphate batteries, providing 8–10 hours of runtime. Fast-charging docks installed near kitchen stations enable 80% recharge in 35 minutes. Predictive maintenance algorithms analyze motor performance data to schedule part replacements before failures occur—a critical feature during peak hours.

Yet, durability remains a hurdle. In high-traffic environments like airport food courts, joint actuators in robotic arms may require monthly servicing due to constant use. Hybrid models combining wheeled bases with modular, easily replaceable upper components are gaining traction to simplify repairs.

Regulatory and Cultural Adoption Barriers

Despite technological readiness, regulatory frameworks lag. In the European Union, food-handling robots must comply with the Machinery Directive and EN 1672-2 hygiene standards, which mandate stainless steel surfaces and antimicrobial coatings. Meanwhile, cultural resistance persists in markets valuing traditional service. A 2024 survey across 12 countries revealed 43% of diners over 50 viewed robotic service as “impersonal,” compared to 18% of those under 30.

Future Trajectories: AI and Customization

Next-generation systems are integrating AI vision for quality control. Cameras inspect dish presentation against predefined standards, alerting staff if garnishes are misplaced. Experimental models like Samsung’s ChefBot even use thermal imaging to monitor food temperature during delivery.

As the technology matures, the focus shifts to personalization. Imagine robots that remember a returning customer’s preferred table location or dietary restrictions—a feature already in beta testing at Silicon Valley’s Eats innovation lab.

In , robotic food service technology represents not just automation, but a redefinition of hospitality logistics. While technical hurdles around adaptability and human acceptance remain, ongoing advancements in sensor fusion, energy management, and AI promise to cement robots as indispensable allies in the global food service industry.