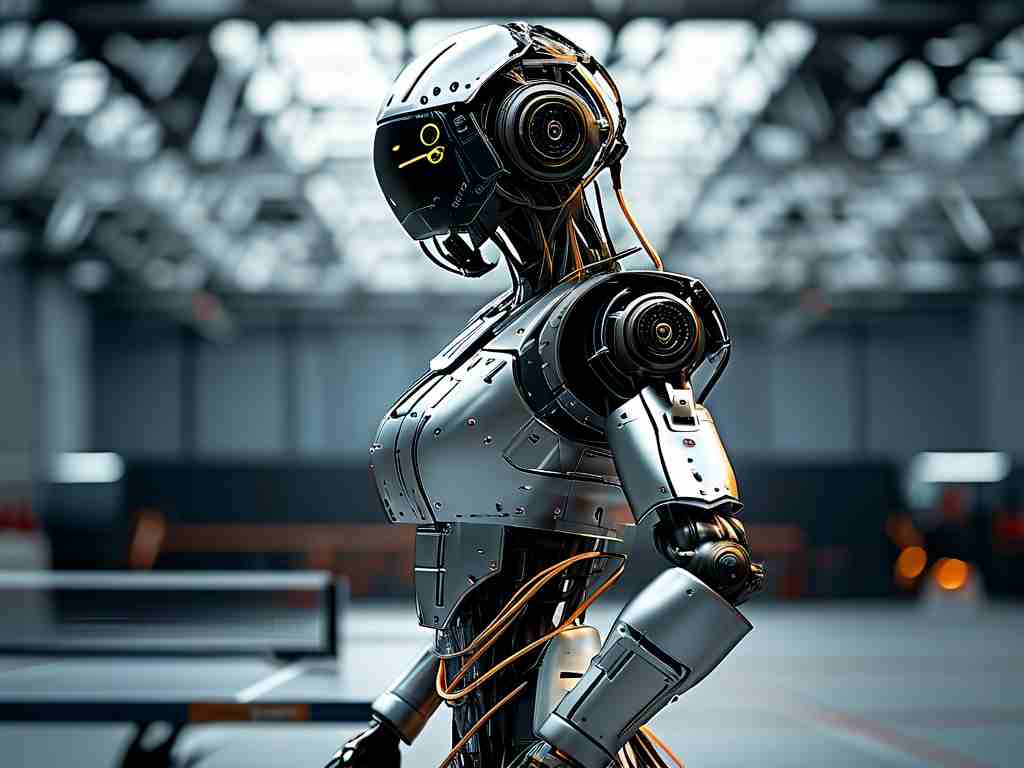

The whirr of motors, the precise glide of an articulated arm, the quiet hum of processing power – these are the signatures of a technological revolution quietly reshaping our world. Smart robotics technology products, far surpassing the clunky automatons of mid-20th century science fiction, are now sophisticated systems integrating advanced mechanics, sophisticated sensors, artificial intelligence, and often, connectivity. They represent not just automation, but augmentation; extending human capabilities, enhancing safety, and unlocking new possibilities across a staggering array of sectors. This integration of intelligence into physical form marks a pivotal leap in how we interact with machines and how tasks are accomplished.

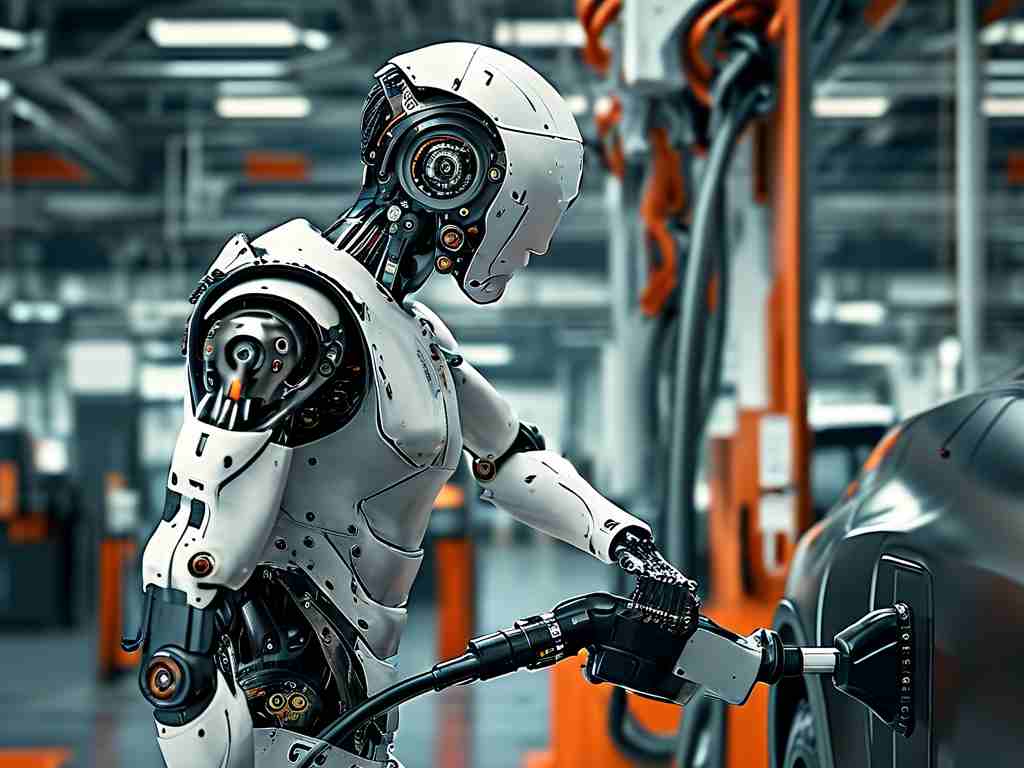

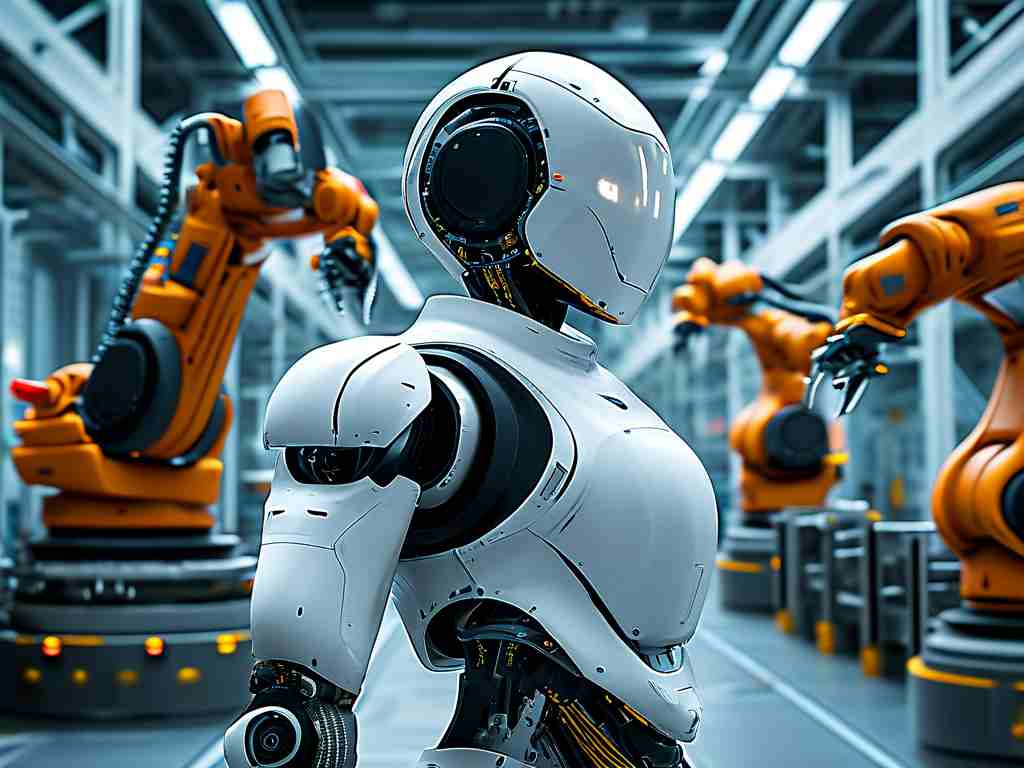

Industrial Metamorphosis: Precision and Productivity Redefined The factory floor remains the most visible proving ground for smart robotics. Gone are the days of single-task, caged machines. Modern industrial robots are collaborative (cobots), designed to work safely alongside human workers without extensive safety barriers. Equipped with force-sensing technology, computer vision, and advanced path planning algorithms, cobots like those from Universal Robots or FANUC can adapt to variations in parts, learn new tasks quickly through demonstration, and handle intricate assembly processes with micron-level precision. This flexibility is crucial in an era demanding mass customization. Beyond assembly, autonomous mobile robots (AMRs) from companies like MiR and Omron navigate dynamic warehouse environments using LiDAR and SLAM (Simultaneous Localization and Mapping) technology, transporting materials efficiently, optimizing logistics, and freeing human workers from repetitive transport tasks. Predictive maintenance algorithms analyze sensor data from robotic arms, foreseeing potential bearing failures or motor issues before they cause costly downtime. The result is not merely faster production, but smarter, more resilient, and adaptable manufacturing ecosystems. Vision systems integrated with robotic arms perform quality inspections at superhuman speeds and accuracy, spotting microscopic defects invisible to the naked eye, ensuring consistent product quality. Welding robots achieve consistent, high-strength seams in automotive production, working tirelessly in hazardous environments filled with sparks and fumes, significantly improving worker safety.

Beyond the Factory: Penetrating Daily Life and Specialized Fields The impact of smart robotics extends far beyond heavy industry. In healthcare, robotic surgery systems like Intuitive Surgical's da Vinci platform provide surgeons with enhanced dexterity, tremor filtration, and 3D high-definition visualization, enabling minimally invasive procedures with smaller incisions, reduced blood loss, and faster patient recovery times. Rehabilitation robots assist patients recovering from strokes or spinal cord injuries, providing consistent, measurable therapy and valuable data for clinicians. Telepresence robots allow specialists to consult remotely, bridging geographical gaps in healthcare access. Service robots are increasingly common: autonomous floor cleaners (like the iRobot Braava Jet) meticulously map and clean homes; robotic lawn mowers (Husqvarna Automower) maintain lawns; and delivery robots (Starship Technologies) navigate sidewalks to bring groceries or meals. Socially assistive robots, such as PARO the therapeutic seal robot, provide comfort and companionship in elder care settings, demonstrating the potential for emotional connection. In agriculture, autonomous tractors guided by GPS and computer vision plant seeds with pinpoint accuracy, while specialized robots perform delicate tasks like fruit picking or precision weeding, optimizing yields and reducing chemical usage. Exploration robots venture into environments too dangerous or inaccessible for humans – deep-sea submersibles mapping ocean trenches, Mars rovers analyzing alien soil, or drones inspecting critical infrastructure like wind turbines or power lines, often using thermal imaging to detect faults.

The Engine Room: Core Technologies Driving Intelligence The "smart" in smart robotics is fueled by a confluence of cutting-edge technologies:

- Advanced Sensing & Perception: Sophisticated sensor suites (LiDAR, radar, high-resolution cameras, depth sensors, inertial measurement units - IMUs, force/torque sensors) provide robots with a rich understanding of their environment. Sensor fusion algorithms combine this data to create a coherent 3D model of the surroundings, essential for navigation and interaction. Computer vision algorithms enable object recognition, pose estimation, and scene understanding. Tactile sensors allow robots to "feel" grip force and texture.

- Artificial Intelligence & Machine Learning: AI is the brain. Machine learning algorithms enable robots to learn from vast datasets, improving their performance over time. Deep learning powers complex perception tasks and decision-making. Reinforcement learning allows robots to learn optimal behaviors through trial and error in simulated environments. Natural Language Processing (NLP) facilitates human-robot interaction through voice commands. AI enables predictive maintenance and adaptive control.

- Edge Computing & Connectivity: Processing sensor data and running complex AI models requires significant computational power. Edge computing brings this processing closer to the robot itself (onboard or nearby), reducing latency for critical real-time decisions (like obstacle avoidance). Connectivity (5G, Wi-Fi 6) allows robots to offload heavier processing to the cloud, receive software updates, and share data with central systems for fleet management and analytics.

- Advanced Actuation & Materials: High-torque, efficient motors, harmonic drives for precise gear reduction, and novel materials (like lightweight composites) enable smoother, stronger, and more energy-efficient movement. Innovations in soft robotics, using compliant materials, allow for safer interaction with fragile objects and unstructured environments. Boston Dynamics' robots showcase incredible feats of dynamic balance and mobility through sophisticated control algorithms acting on advanced hardware.

Navigating the Horizon: Challenges and Ethical Considerations Despite rapid progress, significant challenges remain. Achieving true dexterity and adaptability in highly unstructured, unpredictable environments (like a cluttered home or disaster zone) is immensely complex and an ongoing research frontier. Ensuring robust safety, especially for robots operating near people, demands fail-safe systems and rigorous standards. The high cost of development and deployment remains a barrier for many smaller businesses and applications. Ethical questions loom large: job displacement concerns necessitate proactive workforce retraining strategies; data privacy and security are paramount as robots collect vast amounts of environmental and operational data; algorithmic bias in decision-making must be addressed; and clear legal frameworks for liability, especially in autonomous systems like self-driving cars, are urgently needed. The development of lethal autonomous weapons systems (LAWS) raises profound moral and existential concerns requiring international governance.

: A Collaborative Future Beckons Smart robotics technology products are not about replacing humanity, but rather augmenting our abilities and tackling challenges that are dirty, dangerous, dull, or difficult. They are tools of immense potential, driving unprecedented efficiency, safety, and innovation across industries while gradually integrating into the fabric of our daily lives. The trajectory is clear: robots will become more capable, more affordable, more connected, and more ubiquitous. Successfully navigating this future hinges on thoughtful development, robust ethical frameworks, continuous technological refinement, and a focus on human-robot collaboration. The era of intelligent machines working alongside us is not a distant dream; it is unfolding now, transforming industry and life with every precise movement and intelligent decision. The focus must remain on harnessing this power responsibly to build a more productive, safer, and ultimately, more human-centric future. The collaboration between human ingenuity and robotic capability holds the key to solving some of our most pressing global challenges.