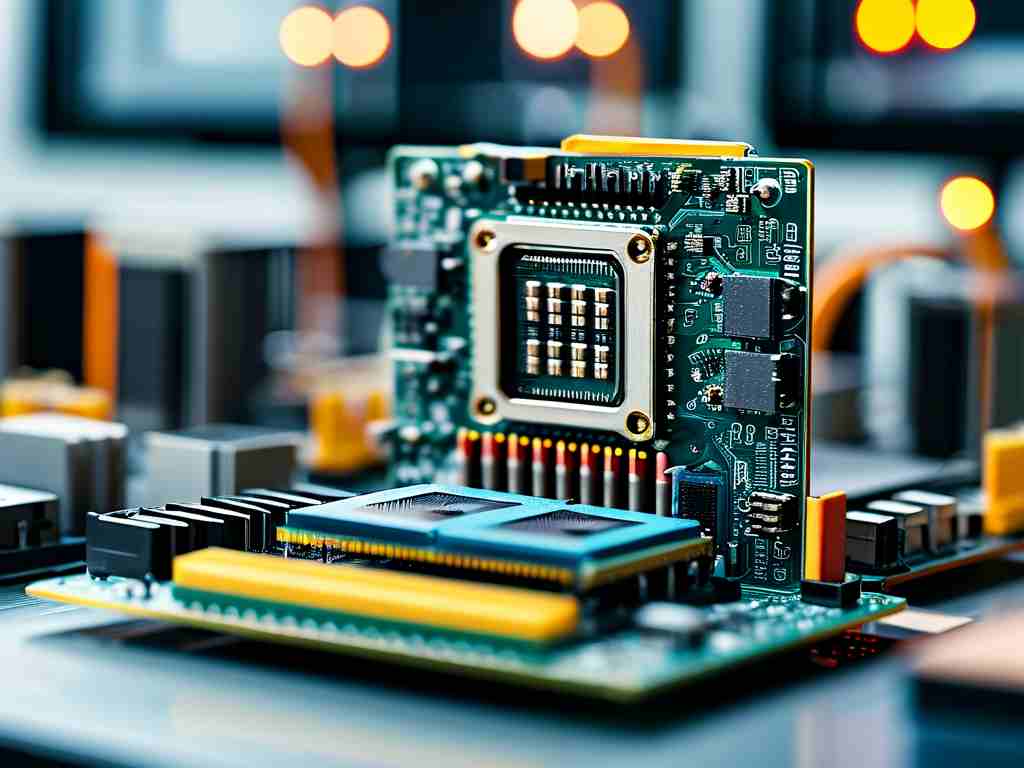

Circuit board embedded development represents the intricate fusion of hardware design and low-level software engineering to create dedicated computing systems. Unlike general-purpose computers, these embedded devices perform specific control functions within larger mechanical or electrical systems. The heart of this process lies in the careful design, fabrication, and programming of printed circuit boards (PCBs) that integrate microcontrollers or microprocessors with essential peripherals and interfaces.

At the hardware inception stage, engineers meticulously select the core processing unit. Choices range from simple 8-bit microcontrollers (MCUs) like the PIC or AVR families for cost-sensitive, low-power tasks, to more powerful 32-bit Arm Cortex-M series processors capable of handling complex real-time operating systems (RTOS) and sophisticated algorithms. Power requirements, I/O pin count, communication protocol needs (UART, SPI, I2C, USB, CAN, Ethernet), memory footprint (Flash, RAM), and computational demands are paramount factors influencing this critical decision. Simultaneously, the schematic capture phase defines the electrical connections between the MCU/MPU and all other components – sensors, actuators, memory chips, communication modules, and power regulation circuits. Component placement and routing during PCB layout are not merely aesthetic exercises; they are crucial for signal integrity, minimizing electromagnetic interference (EMI), managing thermal dissipation, and ensuring manufacturability. High-speed signals demand controlled impedance traces, sensitive analog inputs require guarding, and power planes must deliver stable voltage with minimal noise.

Once the physical PCB is fabricated, assembled, and undergoes rigorous testing (including boundary scan and functional checks), the software development lifecycle commences. This is where the embedded firmware brings the hardware to life. Developers typically work in C or C++, languages prized for their efficiency, hardware proximity, and deterministic execution. Assembly language might be used for ultra-critical timing loops or boot sequences. The development environment usually involves a cross-compiler running on a host machine (like a PC), generating machine code for the target embedded processor, and specialized hardware debuggers (JTAG/SWD probes) for programming and in-circuit debugging.

A foundational task involves establishing a board support package (BSP) or hardware abstraction layer (HAL). This low-level software provides drivers to initialize the system clock, configure GPIO pins, set up communication peripherals, and manage interrupts. It acts as a bridge between the raw hardware and the higher-level application logic, abstracting hardware specifics to improve code portability. For instance, configuring a GPIO pin for output might involve setting specific bits in a configuration register:

// Example for an STM32 using HAL (Simplified)

GPIO_InitTypeDef GPIO_InitStruct = {0};

GPIO_InitStruct.Pin = GPIO_PIN_5; // Target Pin (e.g., PA5)

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP; // Push-Pull Output

GPIO_InitStruct.Pull = GPIO_NOPULL; // No internal pull-up/down

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_LOW; // Output speed

HAL_GPIO_Init(GPIOA, &GPIO_InitStruct); // Initialize GPIO Port A, Pin 5

HAL_GPIO_WritePin(GPIOA, GPIO_PIN_5, GPIO_PIN_SET); // Set PA5 High

Real-time constraints are often critical. Many embedded systems must respond to external events (like sensor readings or communication packets) within strict, predictable timeframes. Techniques like interrupt service routines (ISRs) for immediate reaction and the use of an RTOS (such as FreeRTOS, Zephyr, or ThreadX) for task scheduling, prioritization, and resource management (semaphores, queues) are essential tools. An RTOS allows complex applications to be structured into multiple concurrent tasks while maintaining deterministic behavior.

Analog-to-digital conversion (ADC) is another common requirement for interfacing with real-world sensors:

// Example ADC Reading (Conceptual)

ADC_HandleTypeDef hadc1; // Assume configured previously

uint32_t adc_value = 0;

HAL_ADC_Start(&hadc1); // Start conversion

if (HAL_ADC_PollForConversion(&hadc1, 10) == HAL_OK) { // Wait (10ms timeout)

adc_value = HAL_ADC_GetValue(&hadc1); // Read the converted value

}

// Convert adc_value to actual voltage or sensor unit...

Debugging embedded systems presents unique challenges compared to desktop software. Beyond traditional software debugging (breakpoints, stepping, watch variables), engineers often rely on logic analyzers to capture digital signal timing across multiple pins, oscilloscopes to probe analog signals and power integrity, and serial port outputs for diagnostic messages (printf debugging, often over UART). Techniques like toggling GPIO pins to measure execution time within code sections are invaluable low-level debugging tricks.

Robust embedded firmware must also handle potential faults gracefully. Watchdog timers (WDT) are hardware circuits that reset the processor if the software fails to periodically "kick" them, providing a recovery mechanism from software hangs. Careful memory management is critical, especially in resource-constrained environments without virtual memory; stack overflow detection and disciplined use of dynamic allocation (or avoidance thereof) are common practices.

The applications of circuit board embedded development are vast and touch nearly every industry: automotive engine control units (ECUs) and infotainment, industrial automation PLCs and motor drives, medical devices like insulin pumps and patient monitors, consumer electronics (smartphones, wearables, appliances), Internet of Things (IoT) edge nodes, and aerospace systems. Each domain imposes its own stringent requirements – automotive demands functional safety (ISO 26262), medical requires rigorous validation (FDA), industrial needs robustness in harsh environments, and IoT prioritizes ultra-low power consumption for battery longevity.

Looking forward, trends include the increasing use of multi-core MCUs for complex processing, the integration of AI/ML at the edge for on-device inference, enhanced security features (secure boot, hardware crypto accelerators) to combat growing threats, and more sophisticated power management techniques for energy harvesting and ultra-low-power applications. Wireless connectivity (BLE, Wi-Fi, LoRaWAN, NB-IoT) is becoming ubiquitous in embedded designs. Model-Based Design (MBD) using tools like Simulink is also gaining traction, allowing algorithms to be designed, simulated, and automatically generated into code, potentially accelerating development cycles.

Mastering circuit board embedded development demands a versatile skillset spanning electronics, digital logic, computer architecture, real-time programming, and domain-specific knowledge. It's a discipline where theoretical understanding meets practical implementation, requiring meticulous attention to detail from the schematic symbol to the final machine instruction. Success hinges on the seamless integration of meticulously crafted hardware and precisely engineered software, working in concert to deliver reliable, efficient, and intelligent functionality within the physical world.