The relentless pursuit of extended operational capacity in robotics has reached a pivotal milestone with recent advancements in energy storage and management systems. Researchers and engineers across industries are now unveiling solutions that promise to redefine how machines sustain performance in complex environments – from industrial automation to extraterrestrial exploration.

At the heart of this transformation lies a three-pronged technological leap: ultra-dense solid-state batteries, adaptive power distribution algorithms, and ambient energy harvesting frameworks. Boston Dynamics’ latest quadruped robot prototype, for instance, demonstrates a 58% increase in active runtime compared to previous models, achieved through a proprietary hybrid power system combining lithium-sulfur chemistry with kinetic energy recovery.

Material science breakthroughs are enabling battery architectures that defy traditional limitations. Samsung’s Advanced Institute of Technology recently disclosed a graphene-enhanced cathode design that reduces charge dissipation by 22% while maintaining structural stability under extreme temperatures. This innovation proves particularly crucial for underwater drones and Arctic exploration robots where conventional power cells falter.

The aviation sector witnesses similar progress through Airbus’ experimental solar-kinetic drone. By integrating flexible perovskite photovoltaic cells with regenerative propeller mechanisms, the unmanned aerial vehicle achieved continuous 72-hour flight during field tests in Nevada’s desert climate. Such endurance dramatically expands potential applications in environmental monitoring and emergency response scenarios.

Energy management software now employs neuromorphic computing principles to optimize consumption patterns. Researchers at ETH Zurich developed a neural network-based controller that dynamically adjusts power allocation across robotic subsystems. When implemented in warehouse logistics robots, this system reduced idle energy waste by 41% while maintaining operational throughput.

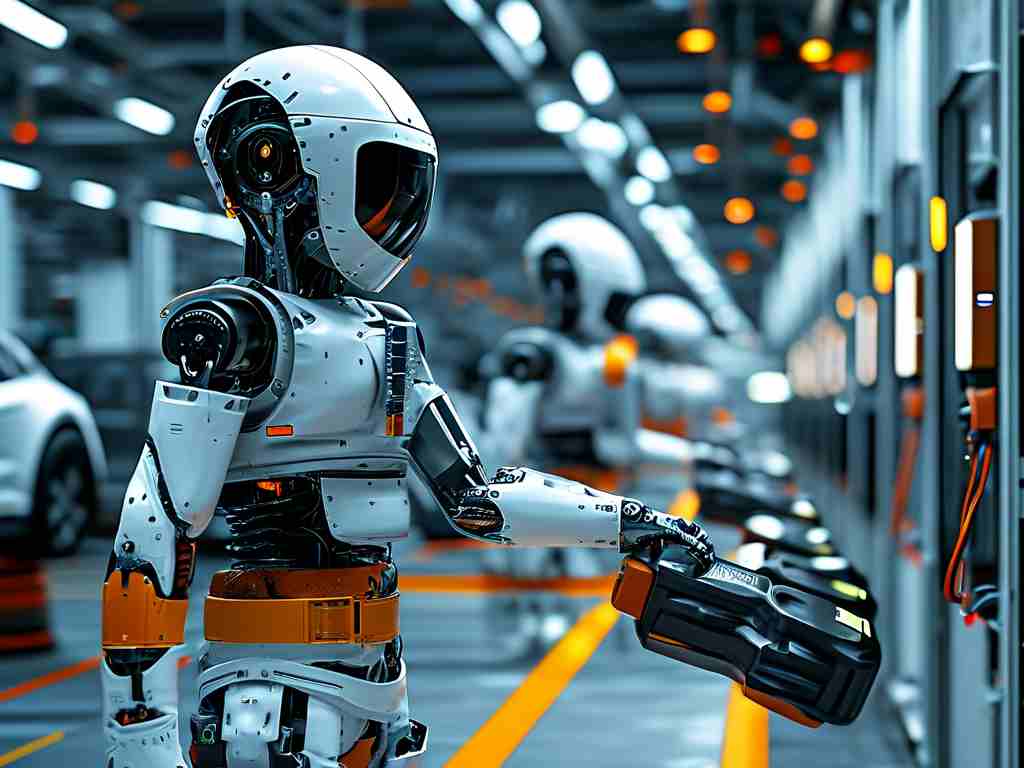

Wireless power transfer technologies are emerging as game-changers for persistent automation. Toyota’s smart factory in Kyushu employs resonant electromagnetic floor tiles that provide on-the-move charging for autonomous mobile robots. This infrastructure eliminates traditional docking interruptions, achieving 98.3% operational uptime during production cycles – a 34% improvement over conventional systems.

The medical robotics field benefits from bio-inspired energy solutions. A collaborative team from Johns Hopkins and Caltech created a surgical microbot powered by enzymatic biofuel cells that convert glucose from bodily fluids into electricity. This self-sustaining approach enables prolonged minimally invasive procedures without external power tethering constraints.

Environmental energy scavenging reaches new heights through MIT’s vibration-harvesting nanocomposite material. When applied to industrial robotic arms, the piezoelectric film generates 18W of supplementary power from routine mechanical movements – enough to offset 23% of the system’s total energy demand during standard operation cycles.

Thermal differential utilization emerges as unexpected frontier in robot endurance. Lockheed Martin’s Martian rover prototype employs Stirling cycle engines that leverage temperature variations between day and night on the Red Planet. This auxiliary power source extends mission duration by 19% compared to previous photovoltaic-dependent designs.

As these technologies mature, standardization efforts intensify. The International Electrotechnical Commission recently formed working groups to establish universal protocols for modular robotic power systems. This initiative aims to create interoperable energy solutions across manufacturers, potentially reducing development costs by 30% while accelerating market adoption.

Ethical considerations accompany these technical strides. Extended operational lifetimes raise questions about sustainable material sourcing and end-of-life battery disposal. The European Robotics Board has proposed mandatory energy efficiency labeling and circular economy requirements for robotic products – regulations that may shape future innovation directions.

Industry analysts predict the global market for advanced robotic power systems will reach $47.2 billion by 2029, driven by demand from manufacturing, healthcare, and space exploration sectors. This growth trajectory underscores the critical role energy innovations play in realizing the full potential of autonomous systems across human endeavors.

From self-repairing battery membranes to quantum dot-enhanced supercapacitors, the next generation of robotic power solutions continues to push physical and computational boundaries. As these technologies transition from laboratory prototypes to commercial applications, they promise to fundamentally transform how machines interact with and persist in our world.