In recent years, Shunde, a manufacturing powerhouse in Guangdong Province, has emerged as a pioneering hub for robotics technology. With the rapid integration of automation and intelligent systems, local industries are undergoing a transformative shift. This article explores how Shunde's robotics guidance initiatives are reshaping production paradigms, addressing challenges, and setting benchmarks for industrial innovation.

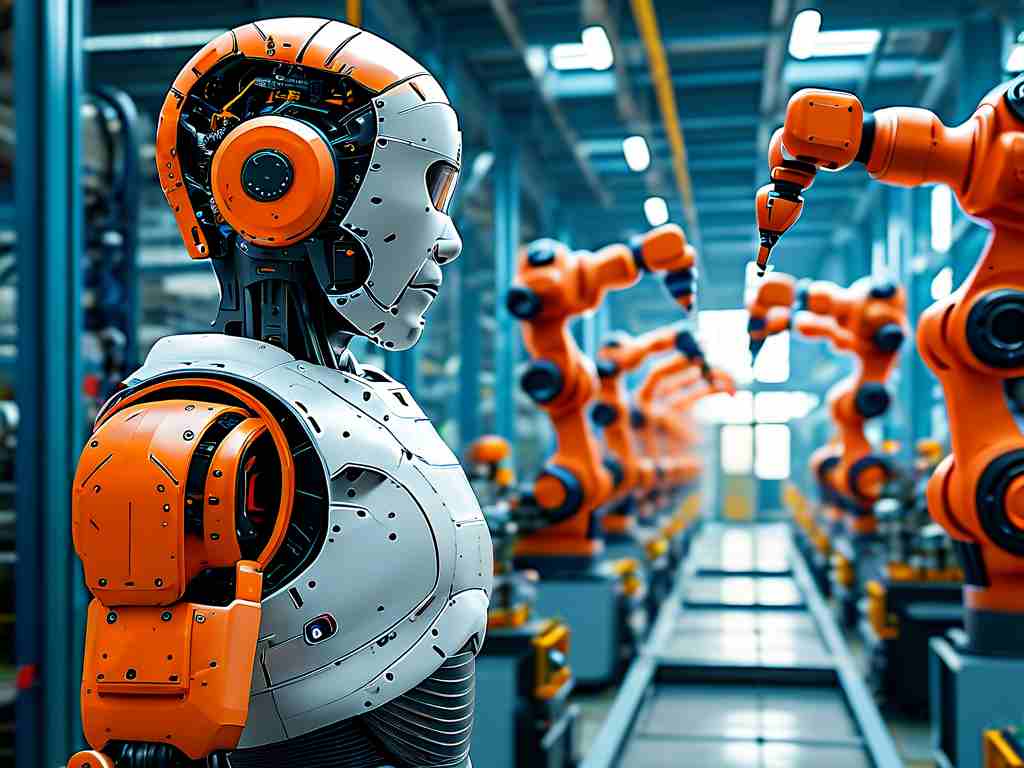

The rise of robotics in Shunde is deeply rooted in its manufacturing legacy. Known for home appliance production and machinery exports, the district faced mounting pressure to upgrade traditional workflows. Rising labor costs and global competition pushed enterprises to seek sustainable solutions. Robotics technology emerged as a game-changer, offering precision, efficiency, and scalability. However, adopting these systems required specialized knowledge, prompting the development of structured technical guidance programs.

Shunde's government and industry associations have played a pivotal role in bridging the technology gap. Collaborative platforms, such as the Shunde Robotics Innovation Center, provide hands-on training for engineers and factory operators. These programs focus on system integration, maintenance protocols, and adaptive manufacturing strategies. For instance, a recent workshop demonstrated how collaborative robots (cobots) can optimize assembly lines in small-to-medium enterprises (SMEs), reducing setup costs by 40% compared to traditional automation.

One notable success story involves a local electrical components manufacturer. By implementing robotics guidance from Shunde's technical experts, the company automated 70% of its welding processes. This not only improved product consistency but also reduced workplace injuries. The project utilized modular robotic units that could be reconfigured for different product lines, showcasing the flexibility of modern automation solutions.

Despite progress, challenges persist. Many SMEs hesitate to adopt robotics due to perceived complexity and upfront investments. To address this, Shunde's guidance framework includes financial subsidies and risk-sharing models. The district's "Automation Voucher" program, launched in 2022, has allocated over ¥50 million to support 300+ factories in initial robotics deployment. Additionally, partnerships with universities ensure a steady pipeline of skilled technicians, combining theoretical knowledge with practical applications.

Looking ahead, Shunde aims to pioneer AI-driven robotics systems. Pilot projects integrating machine learning algorithms with industrial robots are already underway. These systems can predict equipment failures and optimize energy consumption, pushing the boundaries of smart manufacturing. As global industries embrace Industry 4.0, Shunde's robotics guidance model offers valuable insights into balancing technological advancement with workforce development.

In , Shunde's strategic focus on robotics guidance underscores its commitment to industrial leadership. By fostering innovation through education, collaboration, and policy support, the district is not only enhancing local competitiveness but also contributing to broader technological advancements. This approach positions Shunde as a blueprint for regions worldwide seeking to navigate the complexities of modern industrial transformation.