Siasun Robotics, a leading name in China’s automation and robotics industry, has consistently pushed the boundaries of innovation. Established in 2000 and headquartered in Shenyang, the company specializes in industrial robots, smart manufacturing solutions, and cutting-edge automation systems. Its technologies are reshaping industries globally, from automotive manufacturing to healthcare. This article explores the core advancements behind Siasun’s success and their real-world applications.

Core Technologies Driving Siasun’s Robotics

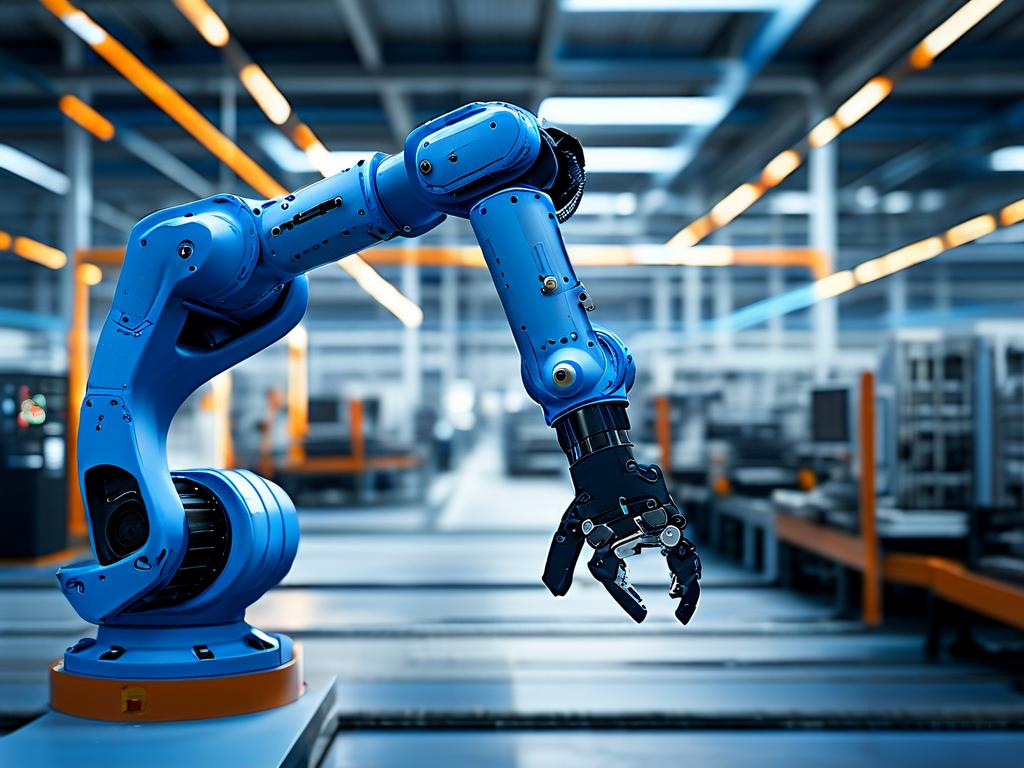

At the heart of Siasun’s achievements lies its proprietary motion control systems. These systems enable robots to perform high-precision tasks with minimal latency, a critical feature for industries like semiconductor manufacturing. For instance, their SCARA robots achieve repeatability within ±0.02mm, making them ideal for assembly lines requiring micrometer-level accuracy.

Another breakthrough is Siasun’s integration of AI with robotics. By embedding machine learning algorithms into robotic controllers, their machines adapt dynamically to environmental changes. A practical example is their autonomous mobile robots (AMRs) used in warehouses. These AMRs utilize real-time data analytics to optimize pathfinding, avoiding obstacles while maximizing efficiency—capabilities demonstrated during the 2022 World Intelligent Manufacturing Summit.

Industry-Specific Applications

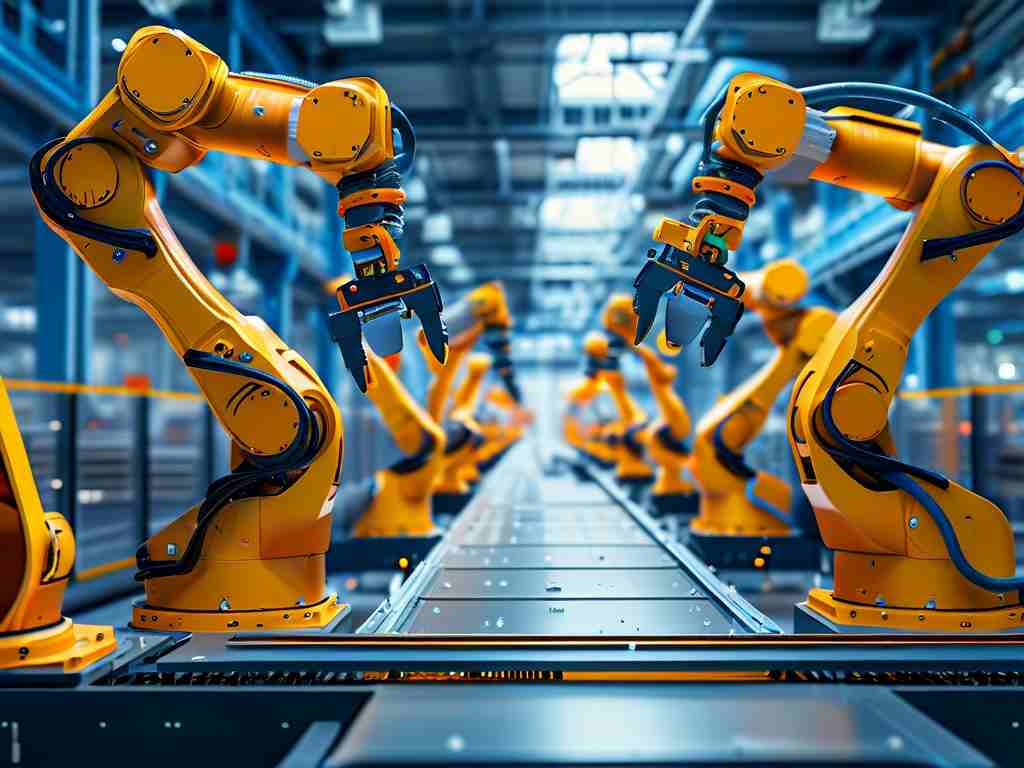

In automotive manufacturing, Siasun’s robotic arms dominate painting and welding processes. Collaborating with major automakers, they’ve reduced production cycle times by 30% through synchronized multi-robot workflows. Their patented collision detection technology also minimizes downtime by predicting mechanical failures up to 48 hours in advance.

The healthcare sector benefits from Siasun’s surgical assistance robots. These systems, compliant with ISO 13485 medical device standards, enhance precision in minimally invasive procedures. During trials at Peking Union Medical College Hospital, their robots reduced operation times for complex surgeries by 25%, showcasing their potential to revolutionize patient care.

Overcoming Technical Challenges

Siasun’s engineers faced significant hurdles in developing robots for extreme environments. For example, their deep-sea exploration robots withstand pressures exceeding 100MPa. By using titanium alloys and proprietary pressure-compensation systems, these robots now assist in underwater pipeline inspections across the South China Sea.

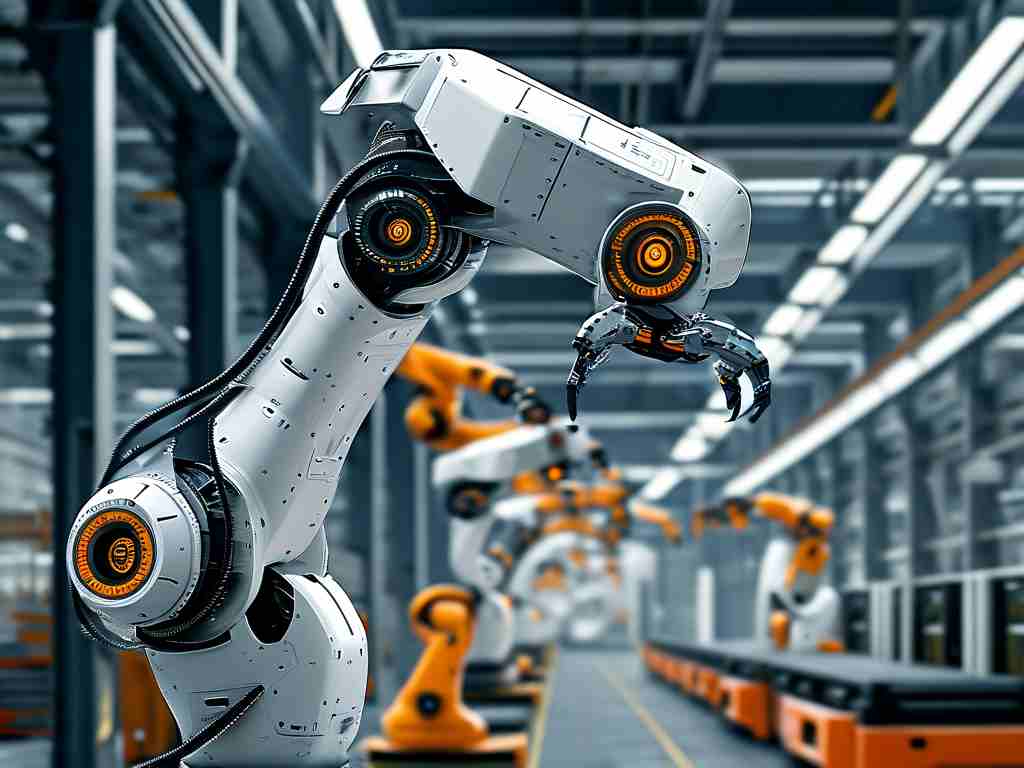

Another milestone was achieving seamless human-robot collaboration. Siasun’s collaborative robots (cobots) feature force-limited joints and vision systems that detect human presence within 0.1 seconds. This innovation earned them the 2023 International Federation of Robotics Safety Award, setting new benchmarks for workplace safety.

Sustainability and Energy Efficiency

Aligning with global decarbonization goals, Siasun introduced energy recovery systems in their robots. Regenerative braking technology in their articulated robots converts kinetic energy into reusable electricity, cutting power consumption by 18%. This feature has attracted partnerships with renewable energy firms deploying robots in solar panel production.

Future Roadmap and Global Expansion

Siasun’s R&D pipeline includes quantum computing-enhanced robots for logistics optimization. Early prototypes processed route-planning algorithms 200 times faster than classical systems during internal tests. The company also plans to establish R&D centers in Stuttgart and Silicon Valley, aiming to capture 15% of the European industrial robotics market by 2026.

Siasun Robotics exemplifies how strategic innovation drives industrial transformation. By merging advanced mechanics with AI and sustainable design, they address both current and emerging challenges across sectors. As automation demand grows, Siasun’s technologies will likely play a pivotal role in shaping the Fourth Industrial Revolution.