Sewing robot technology represents a groundbreaking shift in the textile and manufacturing industries, blending automation with precision stitching to streamline production and reduce human error. This tutorial guide will walk you through the essentials of understanding, setting up, and utilizing sewing robots effectively. Whether you're a hobbyist exploring DIY projects or a professional aiming to optimize workflows, mastering this technology can unlock new levels of efficiency and creativity. Let's dive into the core concepts step by step, ensuring you gain practical insights without overwhelming jargon.

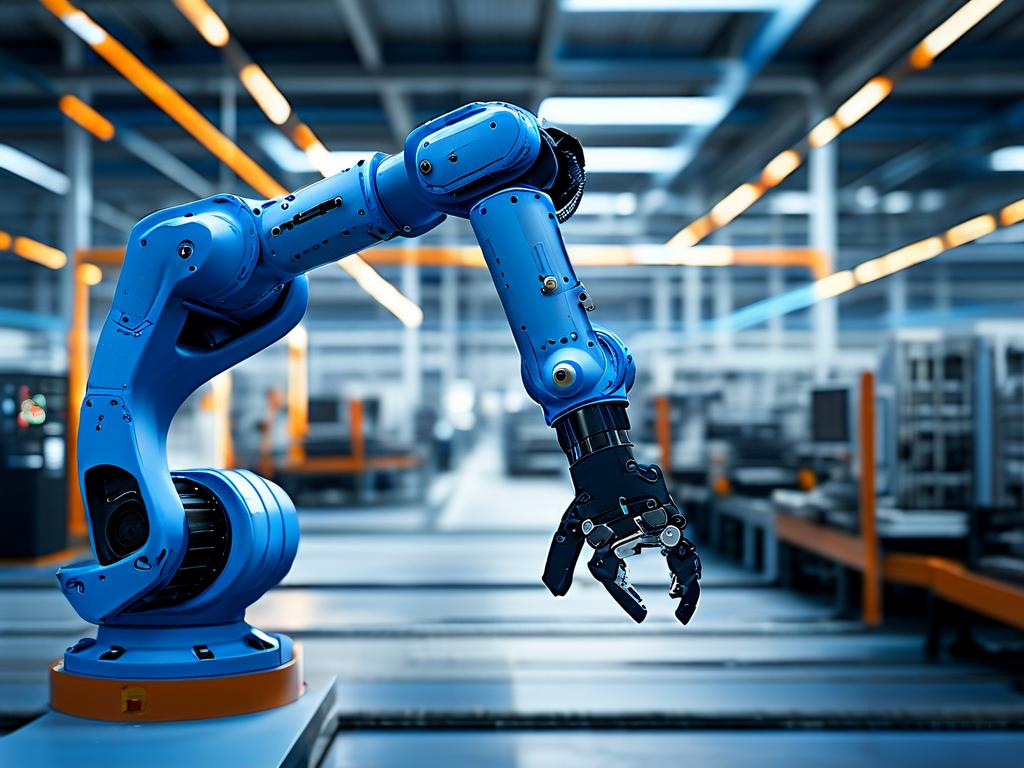

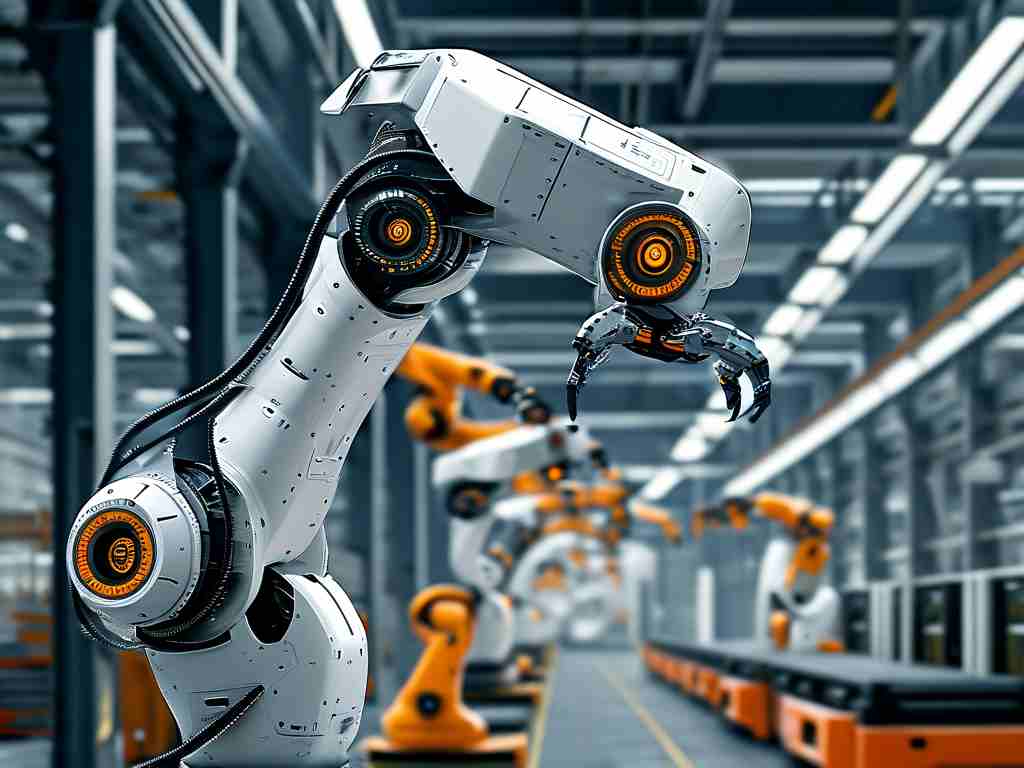

To start, sewing robots are automated systems equipped with advanced sensors, actuators, and software that mimic human sewing actions but with superior accuracy and speed. They typically consist of robotic arms integrated with sewing heads, guided by computer algorithms to handle fabrics ranging from delicate silks to heavy denim. The technology hinges on precise motion control, where servo motors adjust needle positions in real-time based on input data, while vision systems detect fabric edges and patterns to prevent misalignments. For instance, a common setup involves infrared cameras scanning material surfaces, feeding coordinates to the robot's brain for flawless stitching paths. This reduces waste and boosts output in factories by up to 50%, as robots work tirelessly without fatigue. However, beginners often overlook calibration steps, leading to skipped stitches or fabric jams—so always prioritize initial setup checks like tension adjustments and thread path verifications.

Moving into the tutorial phase, let's cover how to program and operate a basic sewing robot using open-source tools. First, ensure your hardware is ready: connect the robot to a power source and a computer via USB or Ethernet, then install necessary drivers. Many models support Python scripting for customization, making it accessible for coders. Below is a simple Python code snippet to control stitching patterns. This example uses the PyRobot library to define a square pattern—ideal for practice runs on scrap fabric. Always test in a safe environment, as improper coding can cause hardware damage.

import pyrobot

# Initialize the sewing robot

robot = pyrobot.SewingRobot(port='COM3') # Adjust port based on your setup

# Define stitching coordinates for a square pattern

coordinates = [(0, 0), (100, 0), (100, 100), (0, 100), (0, 0)]

# Execute the stitching sequence

robot.start_stitching()

for point in coordinates:

robot.move_to(point[0], point[1]) # Move to each coordinate

robot.stitch() # Perform a stitch

robot.finish_stitching() # Secure the thread and lift needle

print("Stitching complete! Check fabric for results.")

After coding, run the script and monitor the robot's movements. Common pitfalls include ignoring thread tension settings—aim for 3-4 on a standard scale to avoid breakage—and skipping fabric clamping, which can lead to slippage. For visual learners, supplement this with video tutorials on platforms like YouTube, focusing on troubleshooting errors like thread birdnesting. Remember, practice makes perfect: start with simple shapes before advancing to complex designs like curves or logos. Additionally, integrate IoT features by connecting to cloud platforms for remote monitoring, which enhances scalability in large-scale operations.

Beyond the basics, explore real-world applications to see sewing robots in action. In fashion design, they enable rapid prototyping of custom garments, such as embroidering intricate details on jackets with micron-level precision. Industrial sectors leverage them for upholstery in automotive or aerospace, where consistency is critical for safety standards. For example, a case study from a denim manufacturer showed how robots reduced defect rates by 30% while handling high-volume orders. On the flip side, ethical considerations arise, like job displacement in traditional sewing roles, so advocate for reskilling programs to foster a balanced workforce. Looking ahead, emerging trends include AI-driven predictive maintenance, where algorithms analyze stitch quality data to preempt failures, and sustainable innovations like using recycled threads to minimize environmental impact.

In , sewing robot technology offers transformative potential, merging craftsmanship with cutting-edge automation. By following this tutorial, you've gained a foundation in setup, programming, and application, empowering you to innovate in your projects. As you experiment, share experiences in online communities to refine skills—continuous learning is key in this fast-evolving field. Embrace the journey, and soon, you'll be creating seamless, high-quality stitches that push boundaries in modern manufacturing and beyond.