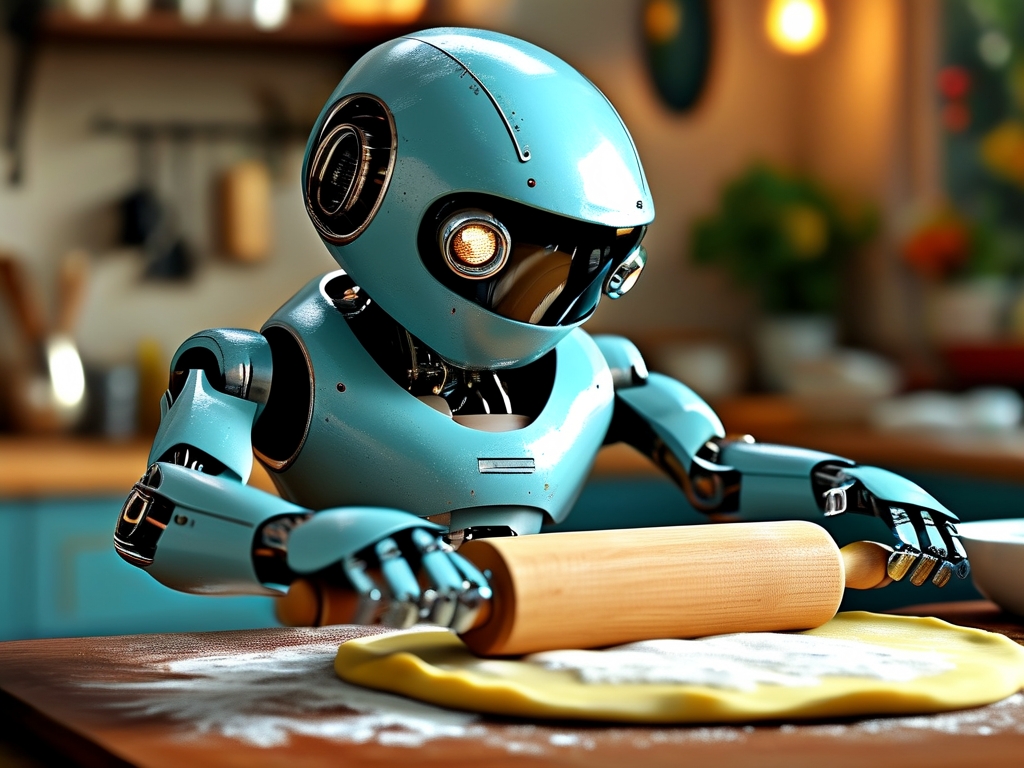

The integration of robotics into culinary arts has revolutionized traditional food preparation methods, with robotic noodle rolling emerging as a groundbreaking innovation. This technology combines precision engineering, artificial intelligence, and material science to replicate and enhance the centuries-old craft of handmade noodle dough preparation. Below, we explore the technical principles, components, and implications of this transformative technology.

1. Core Components of Robotic Noodle Rolling Systems

A robotic noodle rolling system comprises three primary subsystems: mechanical actuators, sensor arrays, and AI-driven control algorithms.

-

Mechanical Actuators:

These mimic human arm movements using multi-axis robotic arms equipped with specialized rollers. Hydraulic or servo motors provide the force required to knead and flatten dough, while adjustable pressure settings ensure compatibility with diverse dough types (e.g., wheat, rice, or gluten-free blends). The rollers are often coated with food-grade polymers to prevent sticking and maintain hygiene. -

Sensor Arrays:

Force sensors embedded in the rollers measure dough elasticity and thickness in real time. Infrared cameras and moisture detectors analyze dough consistency, ensuring optimal hydration levels. Feedback from these sensors enables dynamic adjustments during the rolling process. -

Control Algorithms:

Machine learning models trained on thousands of dough-preparation datasets govern the system. These algorithms predict ideal rolling patterns based on dough type, ambient temperature, and humidity. Reinforcement learning allows robots to "improve" their technique over time, achieving consistency unattainable by human hands.

2. The Physics of Dough Manipulation

Robotic noodle rolling relies on principles of rheology—the study of material deformation. Dough, a viscoelastic substance, requires precise stress-strain balance to develop gluten networks without overworking. Robots apply calculated shear forces through iterative rolling cycles, gradually aligning gluten proteins to create the desired chewiness.

-

Layered Compression:

Unlike human chefs who fold and press dough manually, robots perform programmed layered compression. Each pass reduces dough thickness by a predefined percentage (typically 10–15%), ensuring even texture. This method prevents air pockets and mimics the "hand-pulled" noodle effect. -

Temperature Management:

Dough temperature critically impacts plasticity. Robotic systems integrate Peltier cooling modules or heated rollers to maintain ideal working conditions (20–25°C for wheat dough). This avoids premature fermentation or stiffness caused by environmental fluctuations.

3. AI and Machine Learning Integration

Modern systems employ computer vision and deep neural networks to adapt to variable inputs. For instance:

- A robot can identify uneven thickness using 3D imaging and apply localized pressure corrections.

- Predictive models adjust rolling speed if dough hydration deviates from standards (e.g., due to flour batch variations).

Training these AI models requires vast datasets of successful dough batches, often crowdsourced from professional chefs. Transfer learning techniques allow robots to extrapolate strategies for novel ingredients, such as alternative flours or plant-based additives.

4. Applications and Advantages

- Scalability: Restaurants and factories deploy robotic systems to produce hundreds of noodle sheets per hour with minimal human intervention.

- Consistency: Eliminates human error, ensuring uniform thickness and texture critical for industrial packaging or premium dining.

- Hygiene: Closed-system designs reduce contamination risks, complying with strict food safety regulations.

5. Challenges and Limitations

Despite advancements, challenges persist:

- High Initial Costs: Advanced sensors and AI infrastructure require significant investment.

- Dough Variability: Natural ingredient inconsistencies (e.g., protein content in flour) occasionally necessitate manual recalibration.

- Cultural Resistance: Traditional chefs argue that machines lack the "soul" of handmade noodles, impacting consumer perception in some markets.

6. Future Directions

Emerging trends include collaborative robots (cobots) working alongside chefs and blockchain-enabled quality tracking for ingredient. Researchers are also exploring biodegradable rollers and energy-efficient actuators to enhance sustainability.

In , robotic noodle rolling epitomizes the synergy between culinary heritage and cutting-edge technology. By mastering the science of dough manipulation and leveraging adaptive AI, these systems are redefining the future of food production—one perfectly rolled noodle at a time.