The evolution of robotic equipment technology has reshaped industries and daily life, blending mechanical engineering with artificial intelligence to create systems that redefine efficiency. From manufacturing assembly lines to precision medical procedures, modern robotic systems demonstrate unprecedented capabilities through innovative hardware designs and adaptive software frameworks.

Core Components of Modern Robotics

Contemporary robotic systems rely on four foundational elements: sensory modules, actuation mechanisms, control architectures, and energy systems. Advanced LiDAR sensors and millimeter-wave radar now enable machines to map environments with sub-centimeter accuracy, while shape-memory alloys and pneumatic actuators provide fluid movement in constrained spaces. The integration of edge computing allows real-time decision-making without cloud dependency, critical for applications requiring split-second responses like autonomous vehicles or emergency rescue drones.

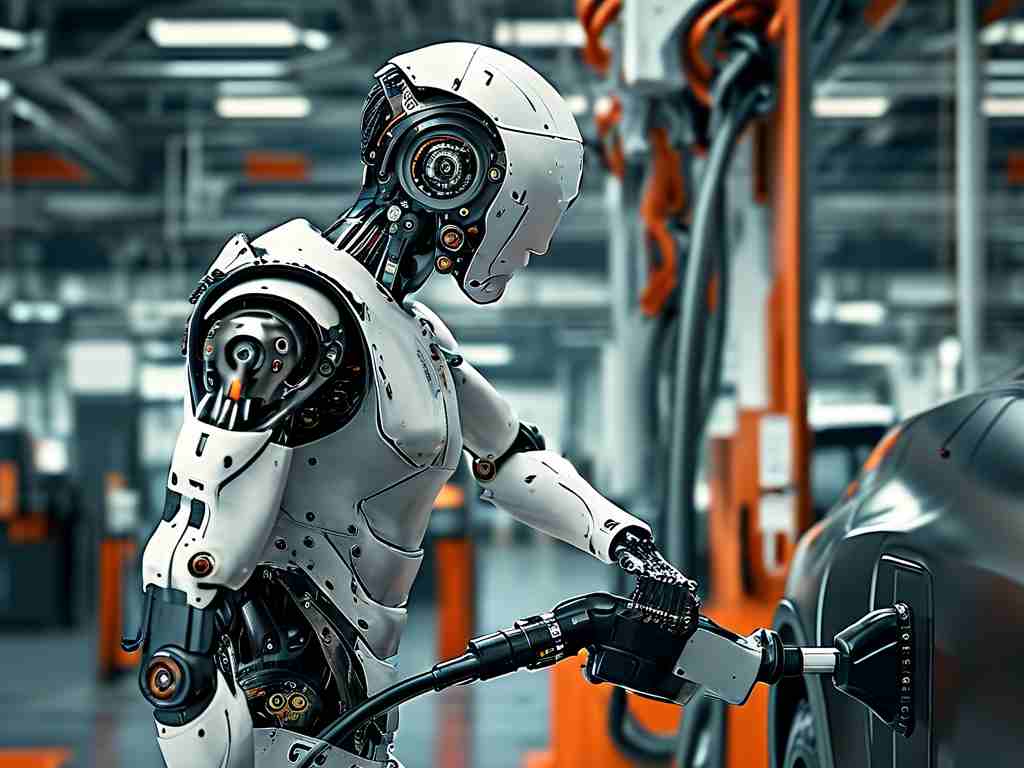

Industrial Automation Breakthroughs

In heavy industries, collaborative robots (cobots) equipped with force-torque sensors work alongside human operators, combining human dexterity with machine precision. Automotive factories deploy robotic arms with machine vision that identify microscopic defects in paint finishes, reducing quality control time by 73%. Mining companies utilize autonomous drilling rigs guided by geological AI models, increasing ore extraction efficiency while minimizing worker exposure to hazardous environments.

Medical Robotics Revolution

Surgical robots like the Da Vinci system have evolved beyond basic laparoscopic assistance. Next-generation platforms incorporate haptic feedback gloves that allow surgeons to "feel" tissue resistance remotely. Nanorobots for targeted drug delivery, currently in clinical trials, use biodegradable magnesium alloys to dissolve after completing vascular repairs. Rehabilitation exoskeletons now adapt gait patterns in real-time using neural interface technology, helping stroke patients regain mobility 40% faster than conventional therapies.

Agricultural and Environmental Applications

Autonomous orchard harvesters combine hyperspectral imaging and robotic grippers to identify fruit ripeness through ethylene gas detection, reducing food waste by 28%. Underwater drones equipped with CRISPR-based sensors monitor coral reef health, detecting early signs of bleaching through genetic analysis of microbial communities. In wildfire management, flame-resistant quadrupeds navigate burning terrains to deploy fire-retardant capsules with GPS-guided precision.

Challenges and Ethical Considerations

Despite progress, energy density limitations persist – current battery technologies restrict untethered operation for high-power robots to under 90 minutes. Cybersecurity vulnerabilities in robotic networks were exposed in 2023 when a major logistics company's warehouse bots were hacked, causing $4.2 million in damages. Ethical debates intensify as humanoid service robots enter consumer markets, prompting new legislation in the EU requiring "non-deceptive design" features to prevent emotional attachment formation.

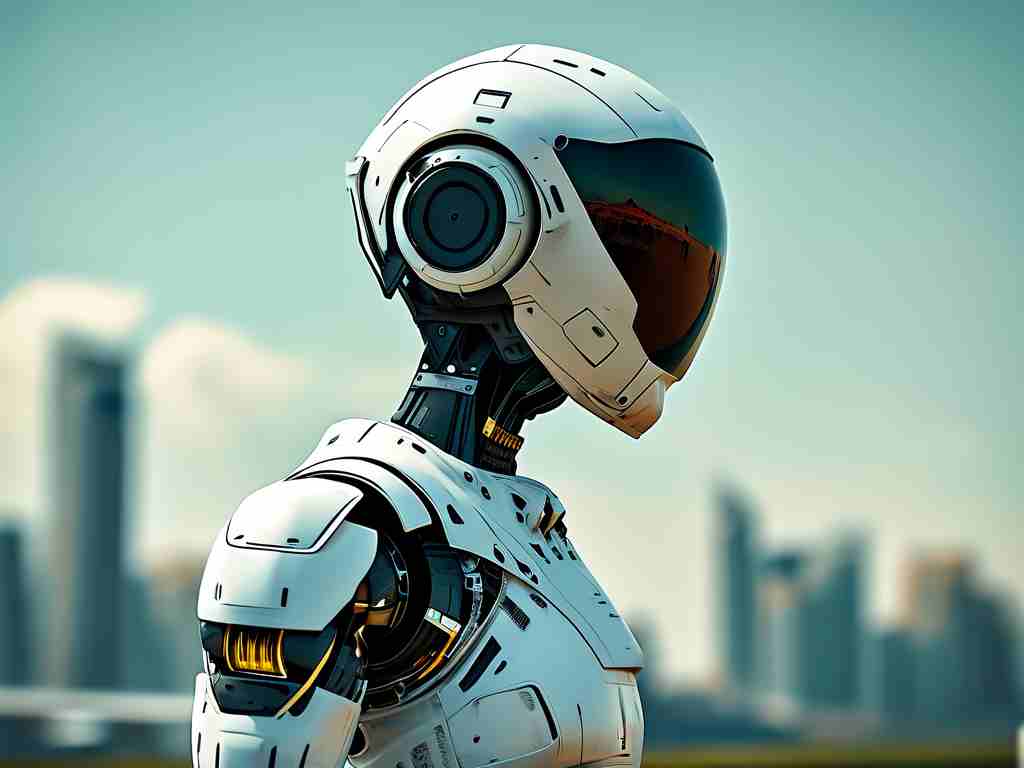

Future Directions

Emerging technologies like quantum-resistant encryption for robotic communication and self-healing polymer skins promise to address current limitations. Research teams at MIT recently demonstrated a robot that reprograms its own kinematics after limb damage, inspired by starfish regeneration. The fusion of robotics with synthetic biology may lead to biohybrid machines – prototypes already exist using modified E. coli colonies for self-cleaning surfaces in food processing robots.

As robotic equipment becomes more intertwined with critical infrastructure, interdisciplinary collaboration between engineers, ethicists, and policymakers will determine how these technologies evolve. The next decade will likely witness robots transitioning from specialized tools to adaptive partners capable of learning and evolving within dynamic environments.

// Sample code for robotic arm path optimization (Python pseudocode):

def calculate_optimal_trajectory(joint_angles, obstacle_map):

from scipy.optimize import minimize

def energy_cost(x):

return sum(abs(x[i] - x[i-1]) for i in range(1,len(x)))

constraints = {'type': 'ineq', 'fun': lambda x: obstacle_clearance(x, obstacle_map)}

result = minimize(energy_cost, joint_angles, method='SLSQP', constraints=constraints)

return result.x