The integration of direct drive technology into robotics has emerged as a transformative force in industrial automation, healthcare, and consumer electronics. Unlike traditional motor systems that rely on gears, belts, or pulleys, direct drive mechanisms eliminate intermediate components by directly coupling the motor to the load. This innovation not only enhances precision but also reduces mechanical complexity, making robots faster, quieter, and more energy-efficient.

The Mechanics Behind Direct Drive Systems

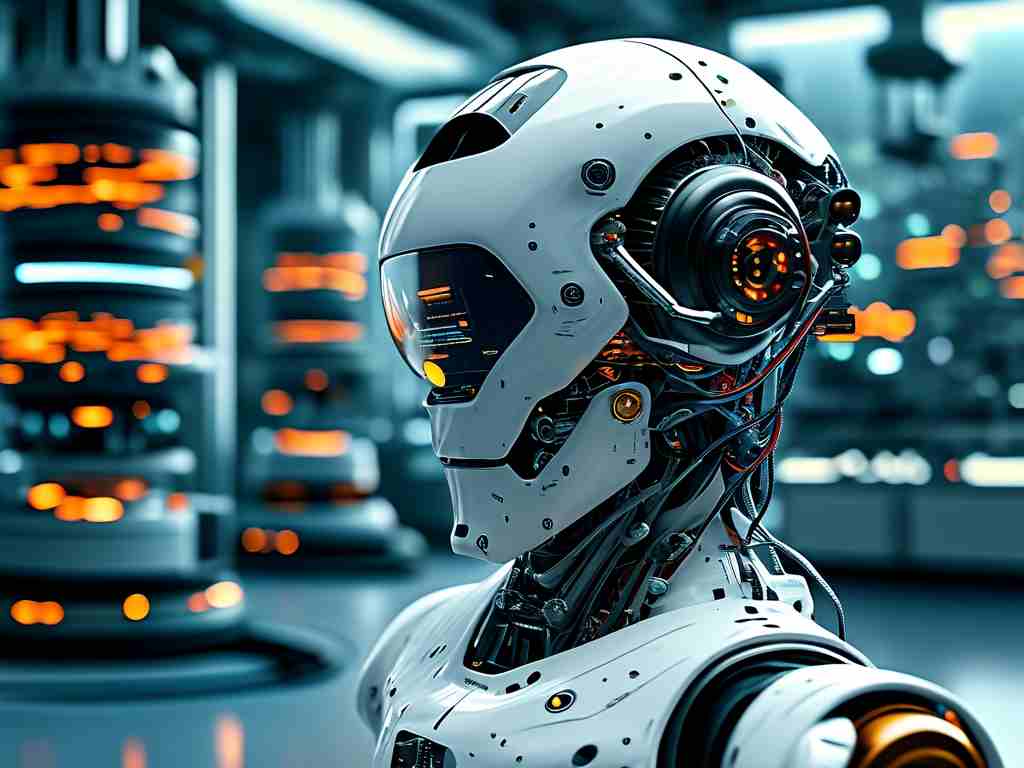

Direct drive technology operates on the principle of electromagnetic force generation. By aligning stator coils and permanent magnets in a circular arrangement, these motors produce torque directly at the point of rotation. This design bypasses friction and backlash common in geared systems, enabling instantaneous response times. For robotic arms in manufacturing, this means unparalleled accuracy in tasks like micro-welding or semiconductor assembly. A study by the International Journal of Advanced Robotics found that direct drive systems reduce positioning errors by up to 70% compared to conventional setups.

Applications in Modern Robotics

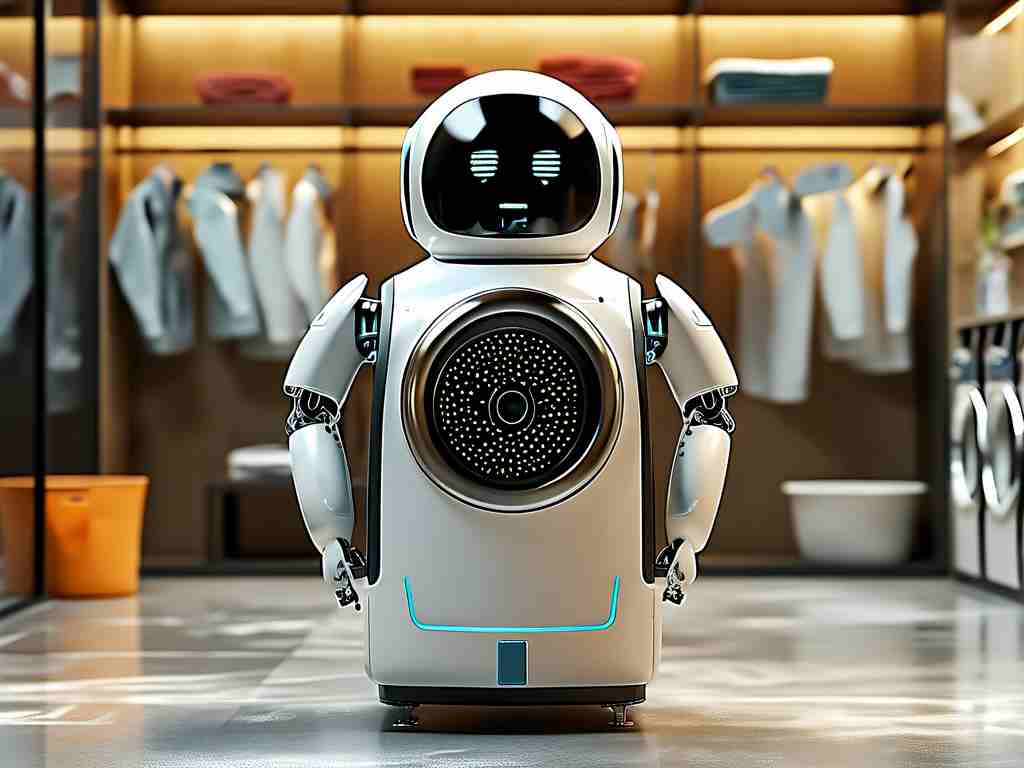

The adoption of direct drive technology spans multiple sectors. In industrial robotics, companies like FANUC and ABB have integrated direct drive motors into high-speed pick-and-place machines, achieving cycle times under 0.3 seconds. Collaborative robots (cobots) also benefit from this technology, as the absence of gears minimizes collision risks in human-robot environments. For instance, Universal Robots’ latest cobot series uses direct drive joints to safely handle delicate materials alongside factory workers.

In medical robotics, direct drive systems power surgical assistants like the da Vinci Surgical System. Their smooth motion and lack of vibration enable surgeons to perform minimally invasive procedures with sub-millimeter precision. Meanwhile, consumer robotics startups are leveraging compact direct drive motors to create agile household robots, such as automated window cleaners that navigate glass surfaces without jerky movements.

Advantages Over Traditional Actuation

One of the most significant advantages of direct drive technology is its durability. With fewer moving parts, maintenance intervals extend by 3–5 times, according to a 2023 report by Robotics Tomorrow. Energy efficiency is another critical factor—direct drive systems waste 15% less power than gear-based alternatives, as validated by the Fraunhofer Institute. Additionally, the technology’s silent operation makes it ideal for noise-sensitive environments like laboratories or residential areas.

Challenges and Innovations

Despite its benefits, direct drive technology faces hurdles. High initial costs and heat dissipation issues have limited its adoption in budget-conscious industries. However, breakthroughs in rare-earth magnet materials and liquid cooling systems are addressing these barriers. Companies such as Yaskawa Electric now offer modular direct drive units with integrated thermal management, cutting installation costs by 40%.

Another frontier is the fusion of direct drive systems with AI. Machine learning algorithms can predict torque requirements in real time, optimizing motor performance. For example, Boston Dynamics’ Atlas robot uses this synergy to execute complex parkour maneuvers, adjusting limb forces mid-jump—a feat impossible with traditional actuators.

The Future of Robotics with Direct Drive

As industries push for smarter and more agile automation, direct drive technology is poised to become the standard. Research from MarketsandMarkets projects the global direct drive market to reach $23.6 billion by 2028, driven by demand in renewable energy and electric vehicles. Emerging applications include exoskeletons for rehabilitation and asteroid-mining robots requiring extreme precision in zero-gravity conditions.

In , direct drive technology is redefining robotic capabilities across sectors. By delivering unmatched speed, accuracy, and reliability, it addresses the growing need for automation that adapts to dynamic environments. As engineers continue to refine this technology, the line between human dexterity and robotic efficiency will blur even further.