The relentless pursuit of manufacturing efficiency, adaptability, and precision has propelled Flexible Robotic Assembly Technology to the forefront of industrial innovation. Unlike traditional rigid automation confined to repetitive, unchanging tasks, this technology empowers robots with the sensory perception, adaptive control, and dexterity necessary to handle complex assembly operations involving variation and delicate components. It represents a paradigm shift, moving beyond brute force and fixed paths towards intelligent, responsive manufacturing cells capable of navigating the complexities of modern product lifecycles and mass customization demands.

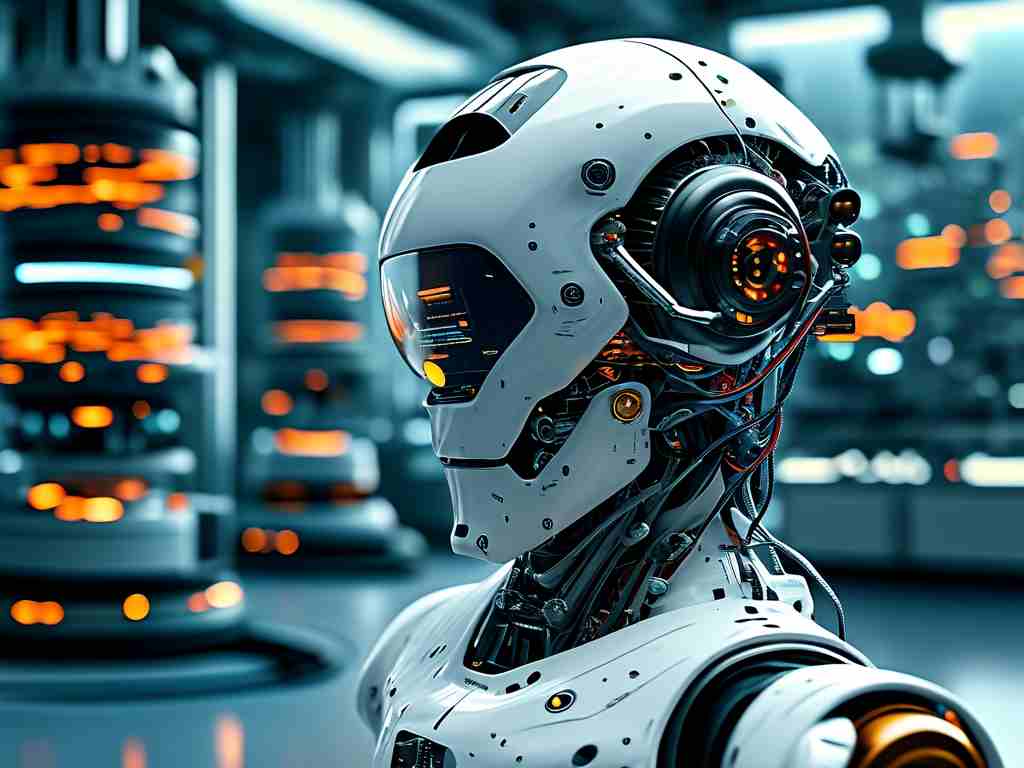

At the heart of this flexibility lie several critical technological pillars. Advanced Sensing and Perception form the robot's eyes and touch. High-resolution 2D and increasingly sophisticated 3D vision systems, often coupled with laser scanners, provide real-time part identification, precise localization, and pose estimation, even when components arrive in random orientations or bins. Tactile and force-torque sensors embedded in the end-effector or wrist deliver micron-level feedback on contact forces. This sensory input is crucial for tasks demanding a delicate touch, such as inserting fragile electronic connectors, mating tight-tolerance mechanical parts without jamming, or applying consistent sealing compounds without damaging substrates.

Complementing perception is Intelligent Control and Compliant Motion. Traditional position control alone is insufficient for complex assemblies where parts might not align perfectly or exhibit slight dimensional variations. Here, technologies like Force Control and Impedance Control come into play. Force Control allows the robot to actively regulate the contact force it exerts, following surfaces or applying precise pressure during insertion or fastening. Impedance Control creates a virtual "springiness" in the robot's motion, enabling it to yield compliantly upon unexpected contact, preventing damage to parts or the robot itself. Remote Center Compliance (RCC) devices, mounted between the robot wrist and the end-effector, provide passive mechanical compliance, allowing minor lateral or angular misalignments to be corrected automatically during peg-in-hole operations, significantly simplifying programming and improving success rates.

Adaptive Programming and Path Planning are equally vital. Offline programming (OLP) software allows engineers to simulate and optimize robot tasks in a virtual environment, drastically reducing costly production downtime. More importantly, modern OLP and robot controllers incorporate adaptive path generation. Based on real-time sensory feedback (e.g., vision-guided correction), the robot can dynamically adjust its programmed path. For instance, if a camera detects a part is slightly offset, the robot recalculates its grasp point or insertion trajectory on-the-fly without stopping the line. Machine learning algorithms are also being integrated to enable robots to learn optimal assembly strategies through demonstration or trial-and-error, further enhancing adaptability.

Versatile End-Effectors (grippers and tools) are the final piece of the puzzle. Flexibility often demands quick tool changes. Robotic tool changers enable a single robot arm to switch between different grippers or specialized tools (screwdrivers, dispensers, welders) within seconds, allowing one robot to perform multiple assembly steps. Grippers themselves have evolved significantly, with options ranging from agile multi-fingered dexterous hands for intricate manipulation to adaptive grippers using granular jamming or soft robotics principles that can conform to a wide variety of object shapes without complex reprogramming. Magnetic, vacuum, and electroadhesion technologies offer non-destructive gripping solutions for sensitive or complex surfaces.

The applications of flexible robotic assembly are vast and transformative. In the automotive sector, robots seamlessly handle the diverse components and variants found in modern vehicles, from intricate dashboard assemblies to battery pack integration for electric vehicles. Electronics manufacturing leverages this technology for the precise, gentle placement of chips, connectors, and displays onto circuit boards, where micron-level precision and anti-static handling are paramount. Aerospace benefits from the ability to assemble complex, low-volume, high-precision components like turbine blades or avionics, often requiring delicate handling of composite materials. Medical device assembly, with its stringent cleanliness requirements and intricate parts, is another prime beneficiary. Even consumer goods and furniture assembly are increasingly automated using flexible systems capable of handling diverse product ranges and packaging configurations.

Despite its immense potential, the implementation of flexible robotic assembly presents challenges. The initial investment in advanced robots, sophisticated sensors, vision systems, and specialized end-effectors can be substantial. System integration, particularly ensuring seamless communication between sensors, controllers, and the robot, requires significant expertise. Programming for true flexibility, especially handling unexpected variations, remains complex and often demands specialized skills. Robust error detection and recovery strategies must be meticulously designed to maintain high throughput when deviations occur. Furthermore, designing products specifically for robotic assembly (Design for Assembly - DfA) can significantly ease the automation process but requires cross-disciplinary collaboration.

Looking ahead, the trajectory points towards even greater intelligence and autonomy. The convergence with Artificial Intelligence (AI) and machine learning will enable robots to learn assembly tasks faster, make more complex decisions based on sensory data, and predict potential failures. Enhanced perception through multi-sensor fusion (combining vision, force, tactile, and even audio) will provide robots with a more comprehensive understanding of their environment and task state. Advancements in collaborative robotics (cobots) will foster closer, safer human-robot teamwork on intricate assembly tasks, leveraging human dexterity and problem-solving alongside robotic precision and endurance. The rise of digital twins – virtual replicas of the physical assembly system – will revolutionize simulation, optimization, and predictive maintenance.

In , flexible robotic assembly technology is not merely an incremental improvement but a fundamental enabler of next-generation manufacturing. By imbuing robots with adaptability, sensitivity, and intelligence, it breaks the constraints of rigid automation. This allows manufacturers to respond agilely to market demands for customization, manage complex product variations efficiently, achieve unprecedented levels of precision and quality, and optimize production costs in an increasingly competitive landscape. As the underlying technologies of sensing, control, AI, and end-effector design continue their rapid evolution, the scope and impact of flexible robotic assembly will only expand, solidifying its role as a cornerstone of the smart factory and the future of industrial production.