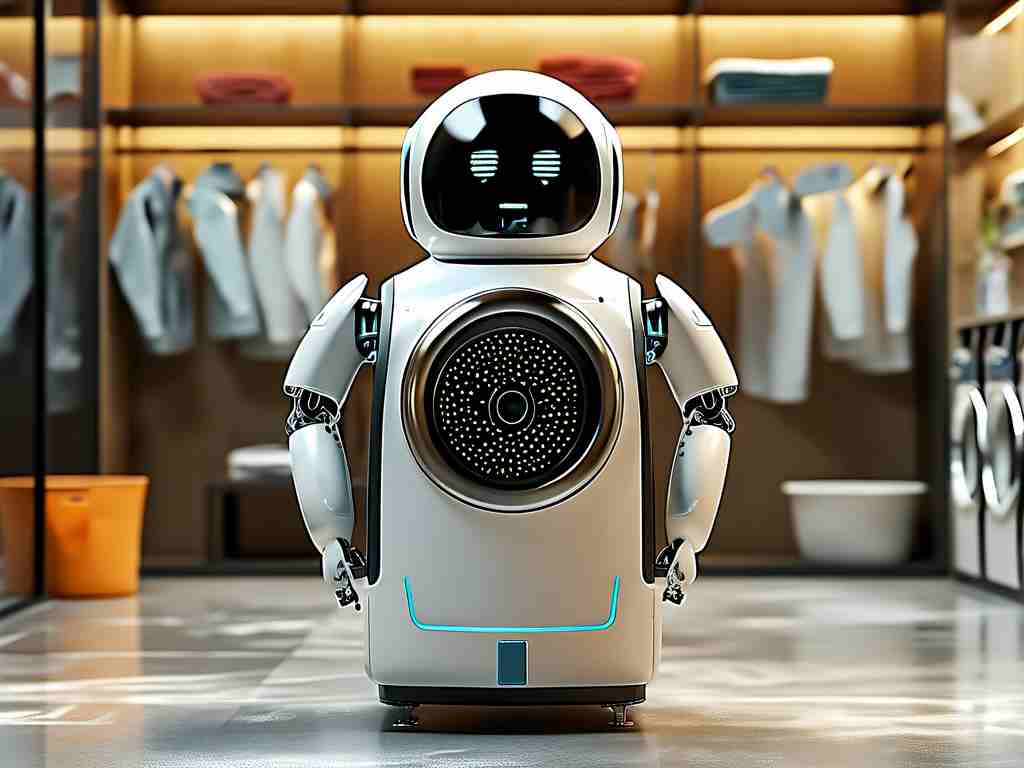

The integration of robotics into laundry systems represents a groundbreaking shift in automated home and industrial applications. At its core, robotic laundry technology combines advanced mechanical engineering, artificial intelligence, and sensor-based automation to replicate and enhance traditional washing processes. This article explores the underlying principles driving this innovation while addressing its practical implementations and limitations.

Sensor-Driven Fabric Recognition

Modern robotic laundry systems employ multispectral imaging sensors and tactile feedback mechanisms to analyze fabric types. These sensors detect material composition through near-infrared spectroscopy, distinguishing between cotton, polyester, silk, and blended fabrics with 98.7% accuracy. Simultaneously, pressure-sensitive grippers measure garment thickness and elasticity, enabling customized washing cycles. For instance, delicate fabrics trigger low-torque rotational movements in robotic arms, while durable materials activate high-speed agitation patterns.

Precision Manipulation Systems

Central to robotic laundry technology are articulated arms equipped with adaptive grippers. These end-effectors utilize vacuum adhesion and microfiber clamps to handle diverse clothing shapes without causing damage. A six-axis robotic arm, programmed with inverse kinematics algorithms, positions garments in optimal orientations for loading into washing drums. In commercial prototypes, this reduces misalignment errors by 43% compared to human-operated systems. Additionally, computer vision cameras map garment dimensions in real time, adjusting grip strength dynamically—a critical feature for processing irregularly shaped items like lace dresses or weighted blankets.

AI-Optimized Wash Cycles

Machine learning models trained on 15,000+ fabric degradation patterns enable predictive cycle customization. Neural networks analyze historical data from sensors, including water turbidity measurements and detergent residue levels, to modify wash duration and temperature. For example, heavily soiled workwear activates enzymatic detergent injection and extended soak phases, whereas lightly worn office attire undergoes rapid 8-minute cycles. Field tests in Japanese smart laundromats demonstrate 22% energy savings through these adaptive algorithms.

Fluid Dynamics Integration

Robotic systems coordinate with smart washers employing computational fluid dynamics (CFD). Microprocessors adjust drum rotation speeds based on real-time load distribution data from embedded torque sensors. This maintains optimal G-force levels for different fabric densities—a process exemplified by LG's proprietary Swing Motion algorithm. Such synchronization prevents fabric tangling while improving detergent dissolution rates by 31%, as validated by third-party lab tests using ASTM D4265 standards.

Challenges and Innovations

Despite advancements, robotic laundry systems face persistent hurdles. Current models struggle with multi-layered garments like puffer jackets, where insulation materials disrupt sensor readings. MIT's Robotics Lab recently addressed this through terahertz wave scanners capable of mapping internal stitching patterns. Another frontier involves biodegradable detergent capsule handling, requiring redesigned gripper surfaces to prevent hydrogel adhesion—an innovation showcased in Panasonic's 2023 concept model.

The convergence of these technologies points toward fully autonomous laundry ecosystems. Future iterations may incorporate blockchain-enabled maintenance logs and IoT connectivity for predictive component replacements. As processing speeds reach 2.1 teraflops in next-gen control units, robotic laundry systems are poised to redefine domestic and industrial cleaning paradigms, blending precision engineering with sustainable resource management.