Embedded platform development requires meticulous planning and execution across multiple technical domains. Unlike general-purpose software engineering, this process demands tight integration between hardware components and low-level software systems. Let’s explore the critical phases of embedded platform development and strategies to streamline workflows while maintaining robustness.

Phase 1: Requirement Analysis and Architecture Design

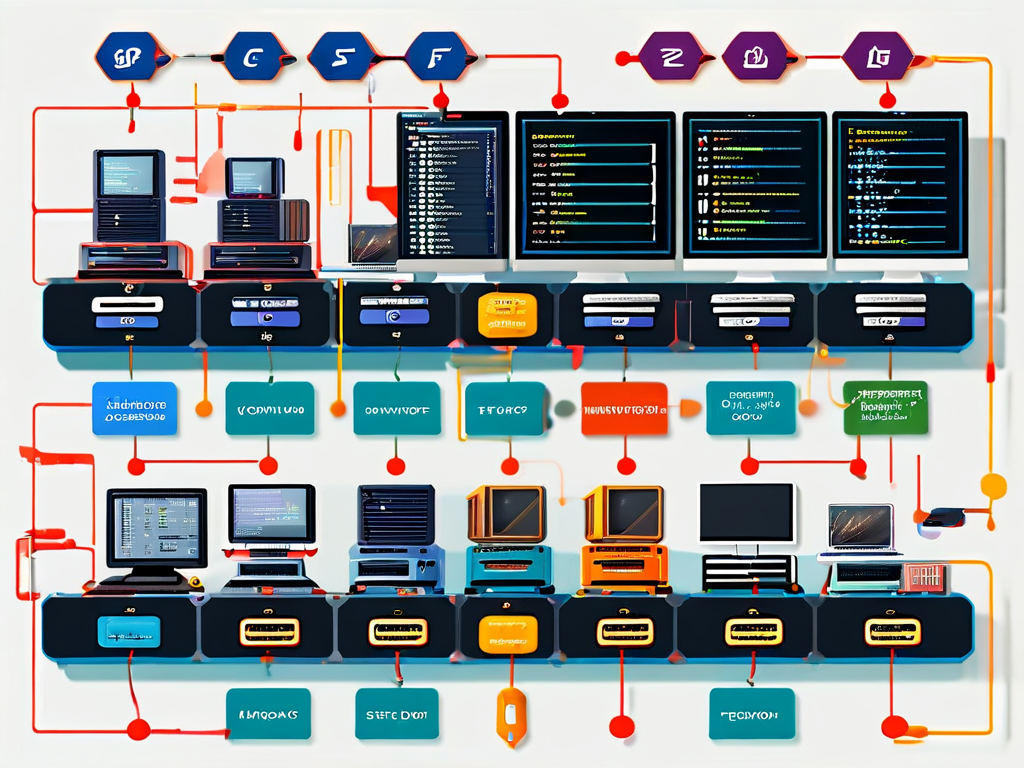

Every successful embedded project begins with precise requirement gathering. Engineers must collaborate with stakeholders to define performance metrics, power constraints, and interface specifications. For instance, a smart thermostat project might require real-time temperature sampling, Wi-Fi connectivity, and ultra-low-power sleep modes. During this phase, creating a system architecture diagram helps visualize interactions between sensors, microcontrollers, and communication modules.

Phase 2: Hardware Prototyping and Validation

Once requirements are finalized, hardware teams develop schematic designs and PCB layouts. Tools like Altium Designer or KiCad enable engineers to simulate circuit behavior before physical production. A common challenge involves balancing component placement for signal integrity and thermal management. Consider a motor control system: improper grounding in the initial prototype could lead to electromagnetic interference (EMI), requiring iterative revisions.

Phase 3: Firmware Development and Cross-Compilation

Software engineers begin coding once hardware prototypes are available. Cross-compilation toolchains (e.g., ARM GCC for STM32 processors) convert high-level C/C++ code into machine-specific binaries. Below is a simplified Makefile snippet for compiling firmware:

CC = arm-none-eabi-gcc

CFLAGS = -mcpu=cortex-m4 -mthumb -Og

TARGET = firmware.bin

all:

$(CC) $(CFLAGS) -o $(TARGET) main.c drivers.c

Real-time operating systems (RTOS) like FreeRTOS or Zephyr are often integrated to manage tasks such as sensor polling and wireless stack operations.

Phase 4: System Integration and Testing

This phase merges hardware and software components while verifying functional requirements. Automated testing frameworks prove invaluable here. For example, a Python script using pytest could validate UART communication:

import serial

def test_uart_response():

ser = serial.Serial('/dev/ttyUSB0', 115200)

ser.write(b'TEST_CMD')

assert ser.read(4) == b'ACK'

Boundary testing becomes crucial—evaluating system behavior under voltage fluctuations or extreme temperatures often uncovers hidden design flaws.

Phase 5: Optimization and Certification

Post-integration optimization focuses on enhancing performance and reducing resource usage. Techniques include:

- Refactoring interrupt service routines (ISRs) to minimize latency

- Applying compiler optimizations (-O2/-O3 flags)

- Implementing sleep states to conserve power

Projects targeting regulated industries (medical, automotive) must undergo certification processes like ISO 26262 or IEC 62304. These standards mandate thorough documentation of design decisions and risk assessments.

Best Practices for Efficient Development

- Version Control for Hardware: Use Git with extensions for managing PCB design files

- Continuous Integration: Automate build and test pipelines using Jenkins or GitHub Actions

- Modular Design: Decouple drivers from application logic to simplify porting across platforms

A case study involving an industrial IoT gateway demonstrates these principles. By adopting a modular firmware architecture, the team reduced debugging time by 40% when migrating from ESP32 to NXP i.MX RT1060 chips.

Mastering embedded platform development requires balancing technical precision with process discipline. By following structured phases—from requirement analysis to certification—and embracing modern toolchains, teams can deliver reliable embedded systems efficiently. As edge computing advances, these methodologies will grow increasingly vital for building next-generation connected devices.