In an era where technological advancement dictates market competitiveness, Deepseek Robotics has emerged as a trailblazer in redefining industrial automation. By integrating adaptive intelligence with modular hardware systems, the company is addressing longstanding challenges in manufacturing, healthcare, and logistics. This article explores how Deepseek’s innovations are reshaping workflows, enhancing precision, and unlocking new possibilities for human-robot collaboration.

The Evolution of Adaptive Robotics

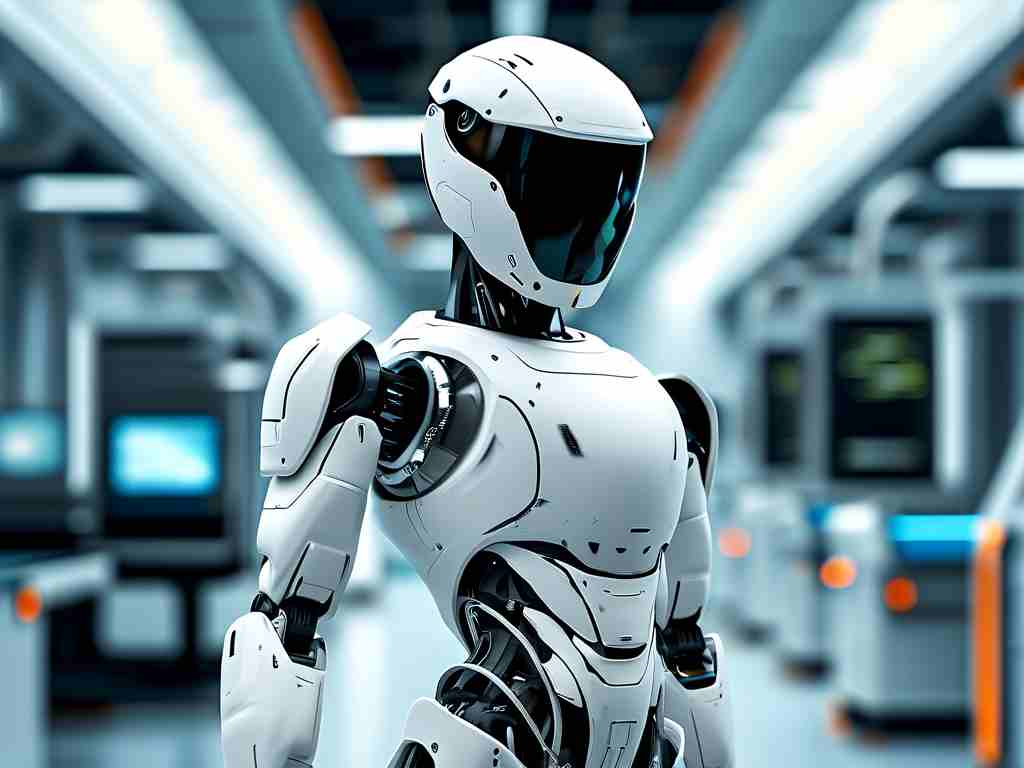

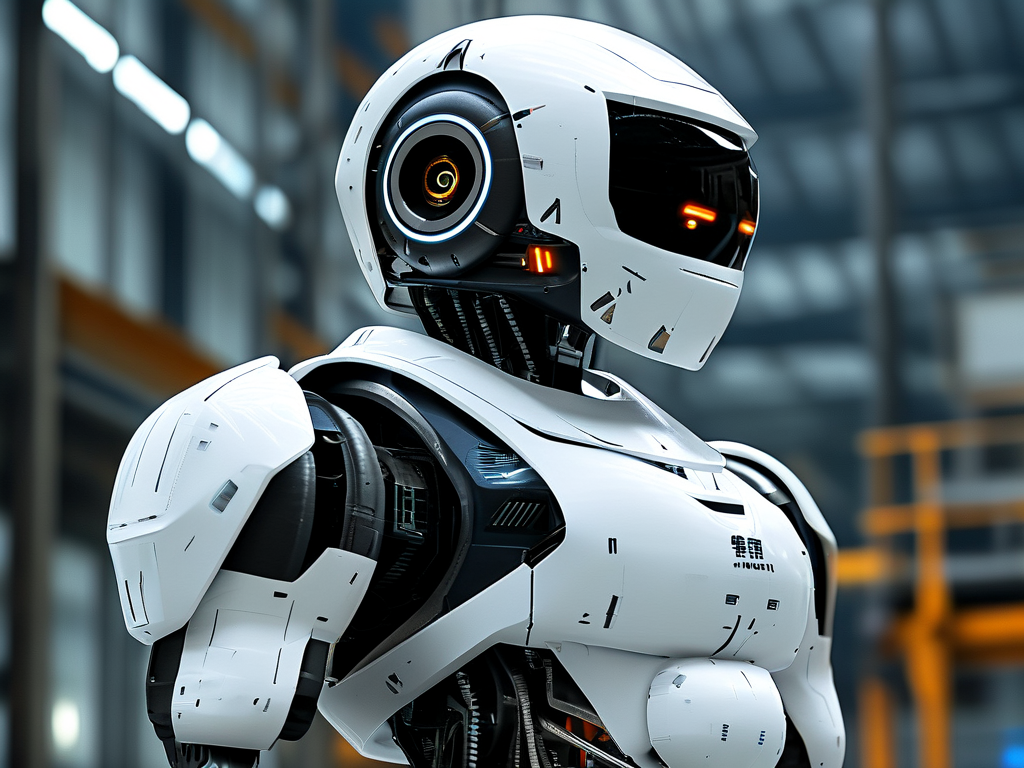

Traditional industrial robots, while efficient, often lack the flexibility to adapt to dynamic environments. Deepseek’s approach centers on “context-aware” robotics—systems capable of real-time decision-making through sensor fusion and machine learning. For instance, their flagship model, the DS-9000, employs a proprietary neural network that processes visual, tactile, and auditory data simultaneously. This enables tasks like sorting irregularly shaped objects or adjusting grip strength during delicate surgical procedures—a leap beyond preprogrammed movements.

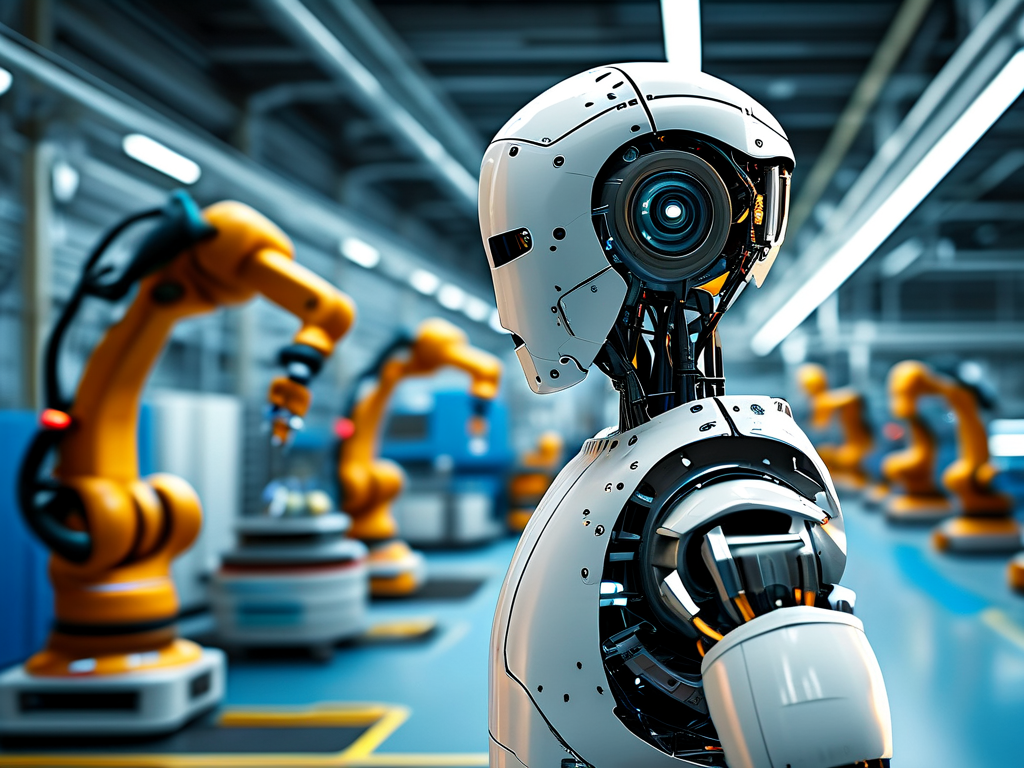

A case study from a German automotive plant illustrates this shift. After deploying Deepseek’s robotic arms, the facility reduced assembly line errors by 43% while handling 15 distinct vehicle models on a single production track. Unlike conventional systems requiring physical recalibration for each design, Deepseek’s solution achieved this through software updates and in-situ learning.

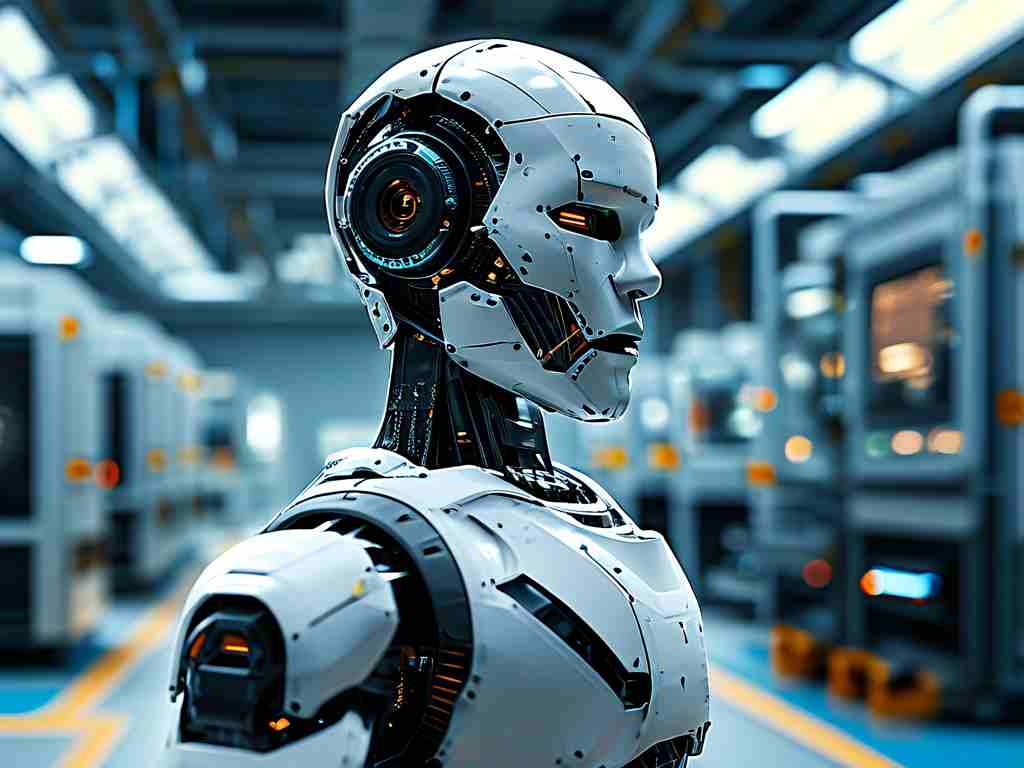

Modular Design for Scalable Solutions

Another cornerstone of Deepseek’s strategy is modularity. Their robotic units feature interchangeable components—grippers, sensors, and mobility bases—that can be reconfigured within minutes. A logistics company in Singapore reported a 78% reduction in downtime after adopting this system, as technicians replaced faulty modules instead of entire units. This design philosophy extends to software: the company’s open API allows third-party developers to create custom plugins, fostering an ecosystem of industry-specific applications.

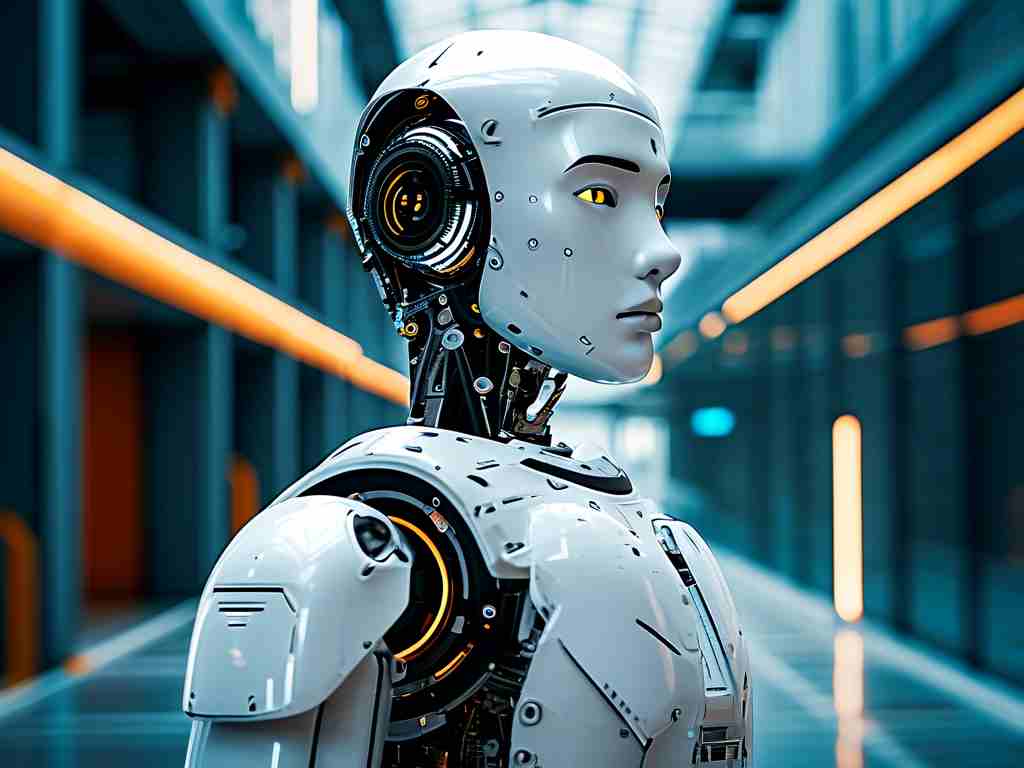

Ethical AI and Human Collaboration

While automation often sparks concerns about job displacement, Deepseek emphasizes collaborative robotics (“cobots”). Their HRC-5 model, equipped with force-limited joints and predictive collision avoidance, works alongside human operators in electronics assembly. Sensors detect when a worker’s hand enters a shared workspace, triggering micro-adjustments to the robot’s trajectory. Early adopters in Japan’s electronics sector have seen a 31% productivity increase without workforce reductions, as employees shifted to supervisory and programming roles.

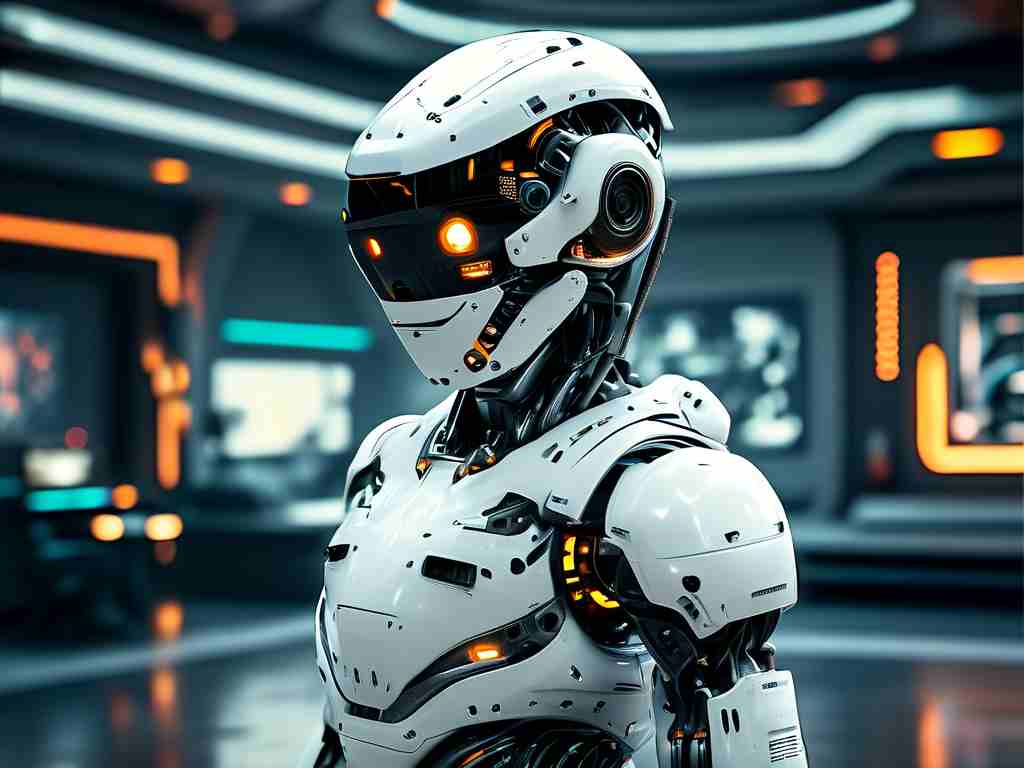

Challenges and Future Directions

Despite progress, obstacles remain. The high computational demands of real-time adaptation require edge computing upgrades, and regulatory frameworks struggle to keep pace with self-learning systems. Deepseek’s R&D head, Dr. Elena Voss, notes, “Our next breakthrough lies in quantum-optimized algorithms to cut decision latency below 50 milliseconds.” Concurrently, the company is expanding into agricultural robotics, testing vine-pruning robots in Italian vineyards that analyze soil moisture and plant health data.

Deepseek Robotics exemplifies how intelligent automation can transcend repetitive tasks, enabling systems that learn, adapt, and collaborate. By prioritizing flexibility and human-centric design, the company is not just advancing robotics but redefining their role in society. As industries worldwide face pressures from labor shortages to sustainability mandates, solutions like Deepseek’s adaptive platforms offer a roadmap for harmonizing technological progress with operational and ethical imperatives.