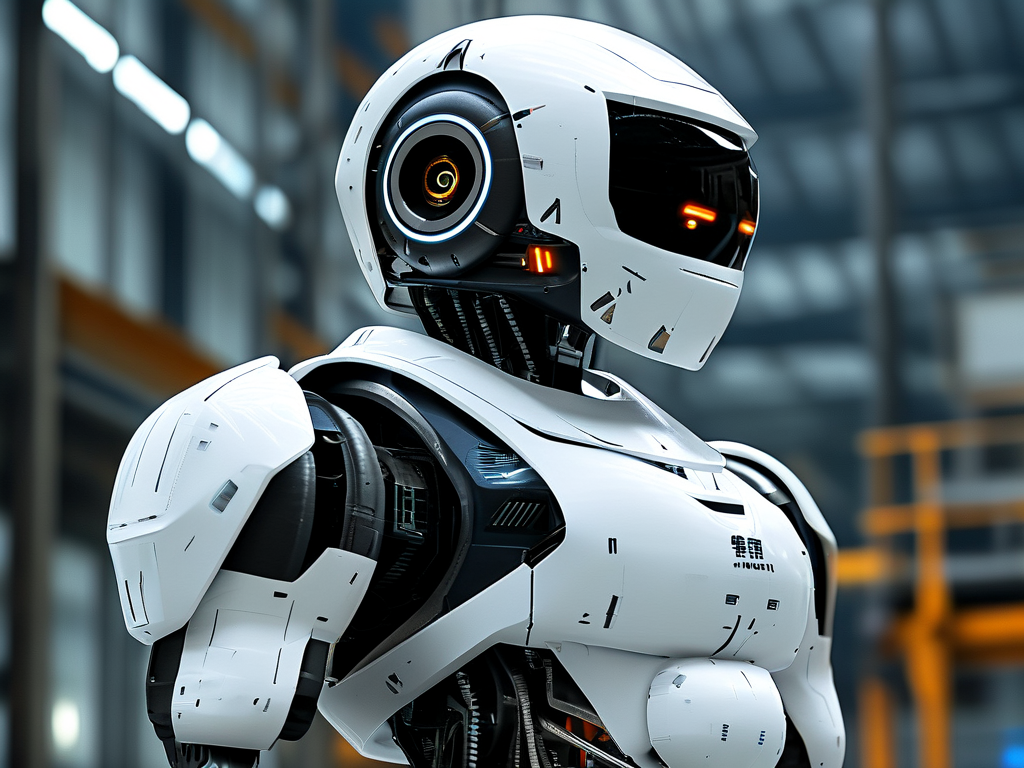

As global automotive manufacturing evolves at breakneck speed, Chery Automobile has emerged as a dark horse in industrial robotics integration. The Chinese automaker's secret weapon lies in its self-developed "Q.Drive" intelligent robotics system, which combines machine vision with adaptive neural networks to achieve millimeter-level assembly precision – a feat that recently helped reduce production defects by 37% at their Wuhu flagship facility.

Unlike conventional robotic arms limited to repetitive tasks, Chery's fourth-generation collaborative robots (cobots) demonstrate unprecedented environmental awareness. Equipped with multi-spectral sensors, these machines can dynamically adjust welding parameters based on real-time metal temperature readings and even predict maintenance needs through vibration pattern analysis. This technological leap enabled the company to shorten model changeover periods from 14 days to 53 hours during their latest production line upgrade.

The true game-changer, however, might be Chery's proprietary "Smart Cell" modular platform. By standardizing robotic workstations into Lego-like units, the automaker achieved 89% equipment reusability across different vehicle platforms. This innovation proved crucial when rapidly retooling factories for electric vehicle production – a strategic move that contributed to their 2023 Q3 export surge of 214% in NEV markets.

Behind these advancements lies a massive R&D push. Chery's robotics division now holds 217 active patents, including groundbreaking work in haptic feedback systems that allow human workers to "feel" a robot's movements through wearable controllers. This human-machine synergy recently earned them the International Federation of Robotics' Innovation Award, marking the first Chinese automaker to receive this honor.

Industry analysts particularly note Chery's strategic partnerships with academic institutions. Their joint laboratory with Harbin Institute of Technology has made strides in quantum computing-optimized path planning algorithms, reducing robotic motion energy consumption by 22%. Meanwhile, collaboration with UBTECH Robotics resulted in mobile inspection robots that autonomously patrol assembly lines, capturing thermal images to prevent equipment failures.

As the automotive world watches, Chery's robotics ambitions extend beyond factory walls. Insider reports suggest active development of service robots for vehicle diagnostics and customer-facing AI assistants capable of explaining technical specifications in 48 languages. With a planned $150 million investment in robotics infrastructure through 2025, this automaker is quietly redefining what's possible at the intersection of mobility and artificial intelligence.