The automotive industry has entered a new era of precision and efficiency, driven by groundbreaking advancements in robotic technologies. From assembly lines to quality control, robots are redefining how vehicles are designed, built, and tested. This transformation is not just about speed—it’s about creating smarter, safer, and more sustainable manufacturing ecosystems.

The Evolution of Automotive Robotics

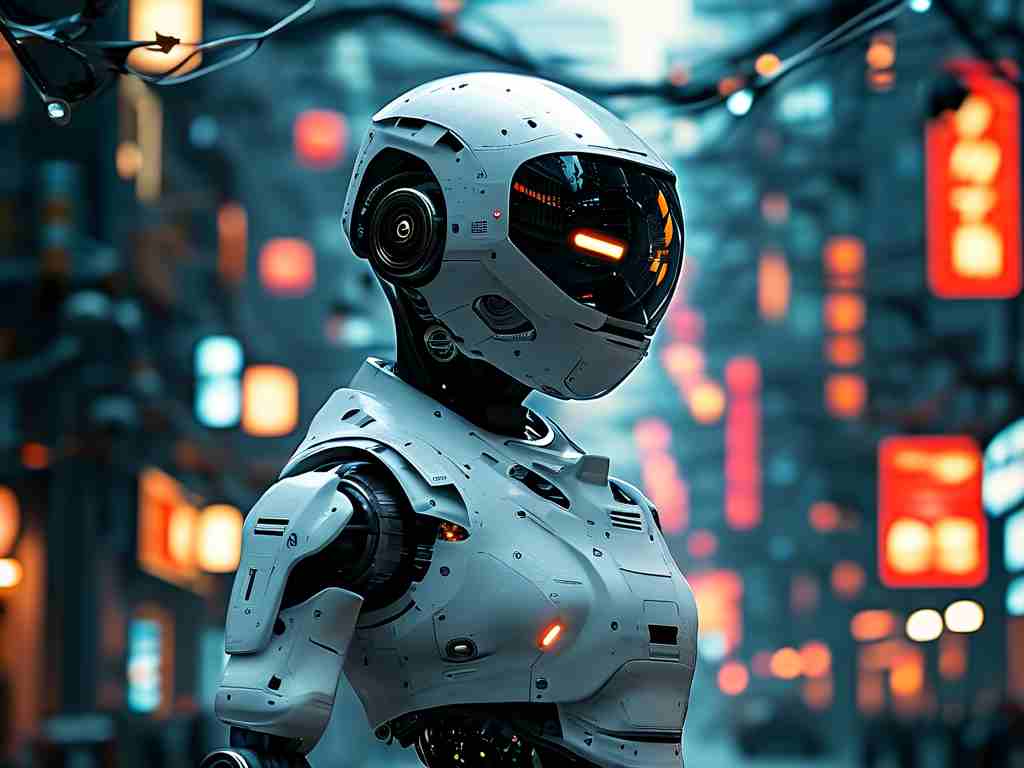

Early automotive factories relied on manual labor and rudimentary machinery. Today, robotic arms with six-axis flexibility dominate production floors, performing tasks ranging from welding to painting with micron-level accuracy. Companies like Tesla and Toyota now deploy fleets of collaborative robots (cobots) that work alongside human technicians. These cobots use advanced sensors to detect human presence, adjusting their speed or trajectory to prevent accidents—a stark contrast to the isolated "safety cages" of traditional industrial robots.

One notable innovation is vision-guided robotics. Equipped with 3D cameras and machine learning algorithms, these systems can identify parts in unstructured environments. For instance, BMW’s Spartanburg plant uses vision-guided robots to install door seals, a task once deemed too delicate for automation. This technology reduces error rates by 40% compared to manual processes.

Smart Factories and Digital Twins

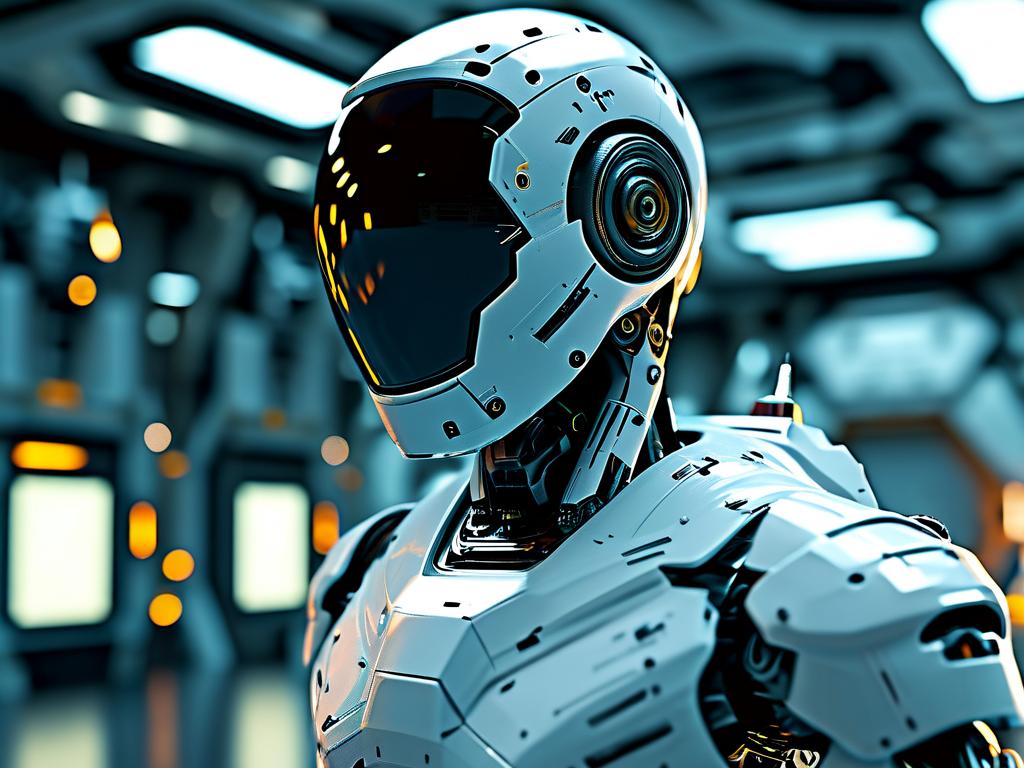

The integration of robotics with IoT and AI has given birth to "smart factories." Here, every robotic unit communicates through a centralized network, enabling real-time adjustments. Volkswagen’s Dresden facility exemplifies this approach. Its production robots are linked to a digital twin—a virtual replica of the physical factory. Engineers simulate production changes in the digital model before implementing them on the shop floor, cutting downtime by 25%.

Autonomous mobile robots (AMRs) add another layer of agility. At Ford’s Cologne plant, AMRs transport components between stations using LiDAR mapping. Unlike traditional conveyor belts, these robots optimize routes dynamically, responding to bottlenecks or priority orders. This flexibility proved crucial during the 2023 semiconductor shortage, allowing Ford to reconfigure production lines in hours rather than weeks.

Robotics in Quality Assurance

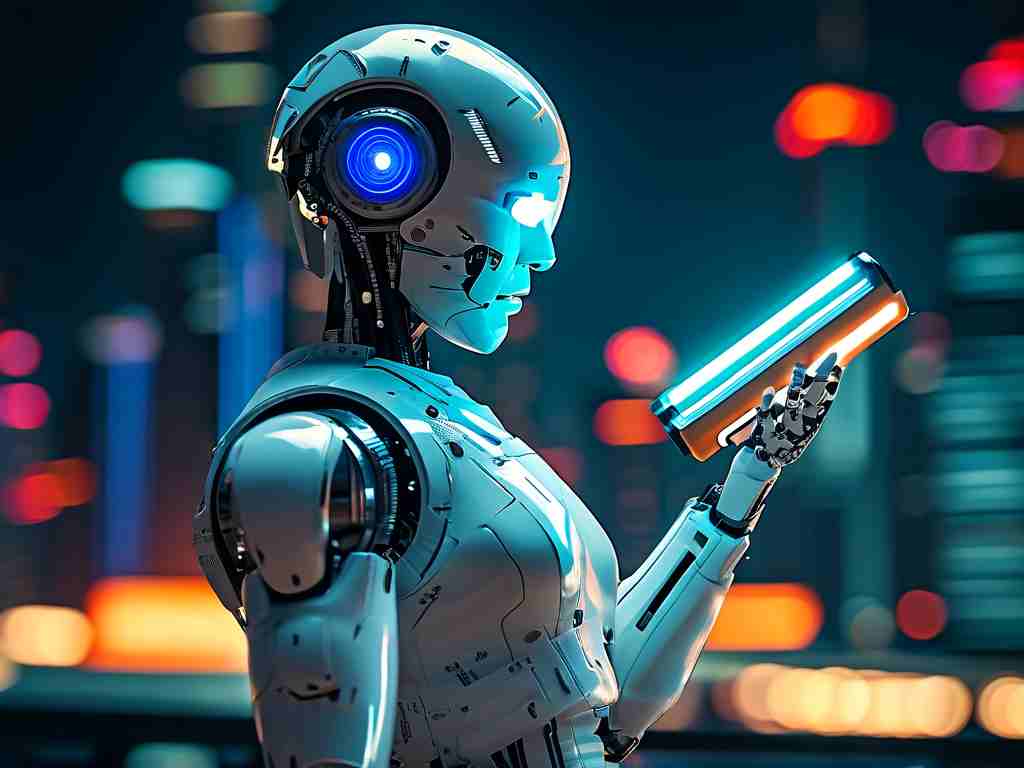

Quality control has seen radical improvements through robotic inspection systems. General Motors employs laser-scanning robots to check body panel alignments within 0.1 mm tolerance. Any deviation triggers instant feedback to welding robots upstream, creating a self-correcting production loop. Similarly, Audi’s paint inspection robots use hyperspectral imaging to detect microscopic imperfections invisible to the human eye.

Testing procedures have also evolved. ABB’s YuMi robot conducts repetitive durability tests on switches and knobs, accumulating data to predict component lifespans. This shift from sample-based testing to 100% inspection ensures defects are caught before vehicles leave the factory.

Challenges and Ethical Considerations

Despite these advancements, challenges persist. The high upfront cost of robotic systems remains a barrier for smaller manufacturers. A single robotic cell can exceed $250,000, requiring specialized programmers and maintenance crews. Additionally, workforce adaptation remains contentious. While automakers argue robotics creates high-skilled tech jobs, unions warn of widening skill gaps. The UAW recently negotiated clauses requiring robotics training programs as part of labor contracts with Stellantis.

Ethical debates also surround data security. Connected robots generate terabytes of operational data, raising concerns about intellectual property theft. In 2022, a Chinese automaker faced allegations of hacking into a German competitor’s robotic networks to steal battery assembly techniques—a case currently under EU investigation.

Future Horizons: Human-Robot Synergy

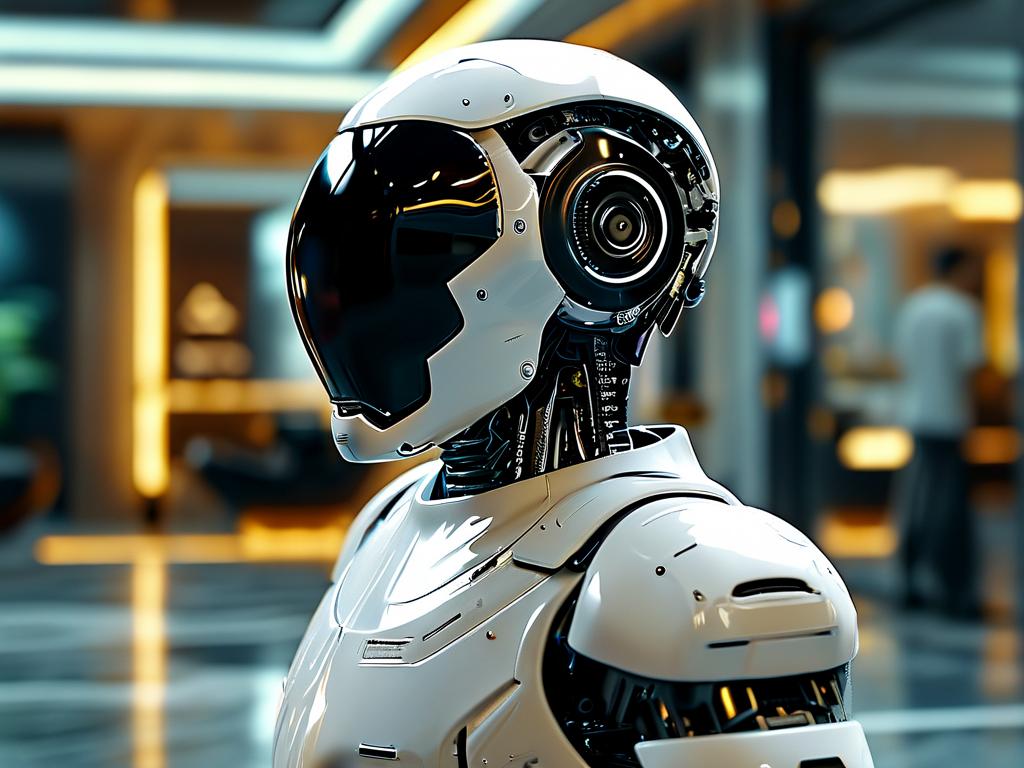

Looking ahead, the focus shifts to human-robot collaboration. Hyundai’s Boston Dynamics acquisition hints at future scenarios where quadruped robots inspect undercarriages, while exoskeletons augment workers’ strength. Researchers at MIT are developing "tactile robots" with artificial skin capable of handling fragile components like wiring harnesses.

Another frontier is sustainable robotics. BMW recently unveiled solar-powered painting robots that reduce energy consumption by 30%. Meanwhile, Renault’s "circular economy" robots disassemble end-of-life vehicles, recovering 95% of materials for reuse.

As the industry accelerates toward electrification and autonomous driving, robotics will play an even greater role. Mercedes-Benz’s upcoming EV platform features robots that install battery packs in sealed, oxygen-free chambers—a process critical for lithium-ion safety.

The marriage between automotive manufacturing and robotics is no longer optional but imperative. With global competition intensifying and consumer demands evolving, automakers must embrace these technologies to stay relevant. However, success hinges on balancing innovation with workforce development and ethical practices. As factories grow smarter, the true test lies in creating systems where humans and machines don’t just coexist but mutually thrive.