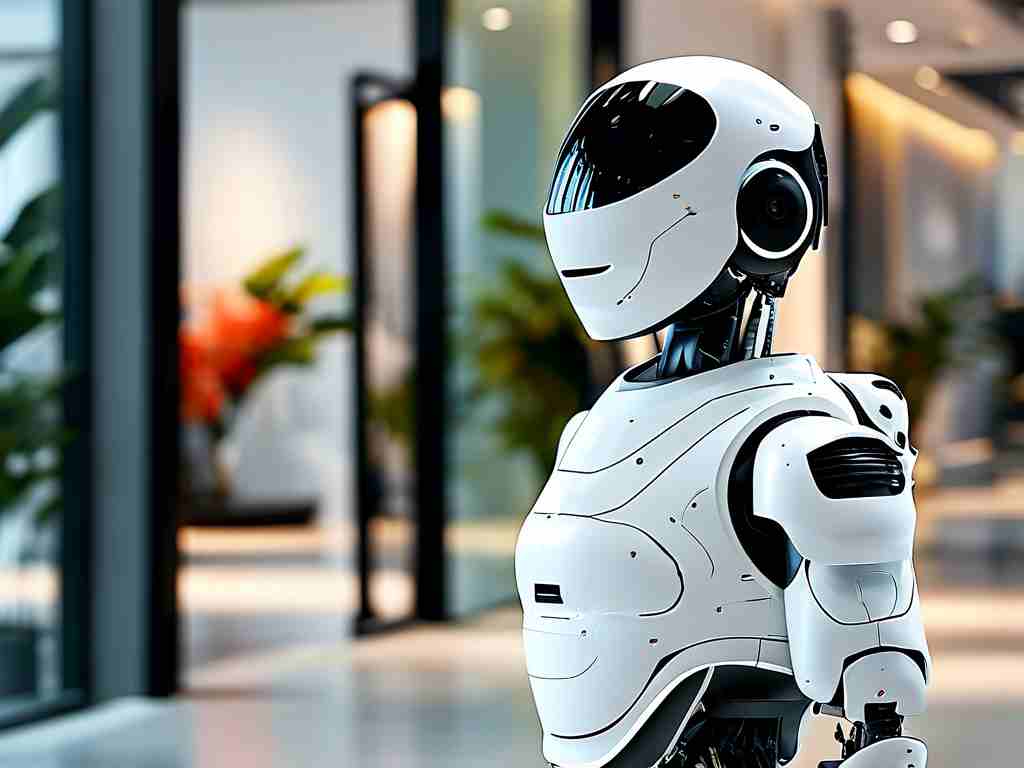

Dongguan, a bustling manufacturing hub in Southern China, has emerged as a pioneering force in adopting inspection robot technology to revolutionize its industrial landscape. This innovation involves deploying autonomous robots equipped with advanced sensors and artificial intelligence to perform routine checks across factories, power plants, and infrastructure sites, ensuring safety, efficiency, and cost savings. As global industries shift towards automation, Dongguan's embrace of this tech underscores its commitment to maintaining a competitive edge in the modern economy.

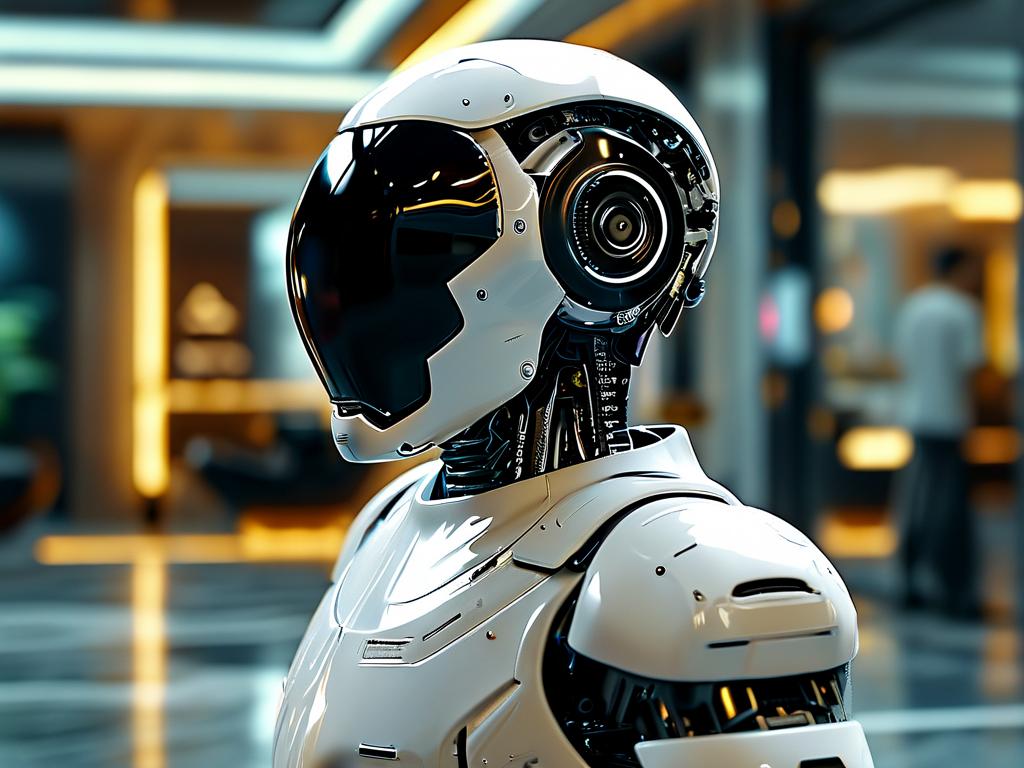

The core of inspection robot technology lies in its ability to automate tedious and hazardous tasks that were traditionally handled by human workers. For instance, in Dongguan's sprawling electronics factories, robots now navigate complex assembly lines using computer vision to detect defects in real-time. These machines are programmed with machine learning algorithms that allow them to learn from each inspection cycle, improving accuracy over time. Beyond manufacturing, they are deployed in critical sectors like energy, where they monitor pipelines for leaks or structural weaknesses, reducing the risk of accidents and costly downtimes. This shift not only boosts productivity but also addresses labor shortages, as skilled workers can focus on higher-value activities while robots handle the repetitive work.

Dongguan's rapid adoption of inspection robots is driven by its dense industrial base, which includes thousands of factories producing everything from consumer electronics to automotive parts. The city's government and private enterprises have invested heavily in research and development, collaborating with tech firms to tailor solutions to local needs. A notable example is the integration of these robots in smart factories, where they work alongside human teams to conduct 24/7 surveillance, ensuring compliance with strict quality standards. This synergy has led to measurable outcomes, such as a 30% reduction in inspection times and a significant drop in workplace injuries, according to industry reports. However, challenges persist, including the high upfront costs of deploying these systems and the need for continuous software updates to handle evolving operational demands.

Looking ahead, the future of inspection robot technology in Dongguan appears promising, with trends pointing towards greater AI sophistication and broader applications. Innovations like swarm robotics, where multiple units coordinate for large-scale inspections, are on the horizon, potentially transforming sectors like logistics and urban management. As Dongguan continues to innovate, it sets a benchmark for other industrial regions worldwide, demonstrating how robotics can drive sustainable growth. In , this technology not only enhances Dongguan's industrial resilience but also paves the way for a smarter, safer future in global manufacturing.