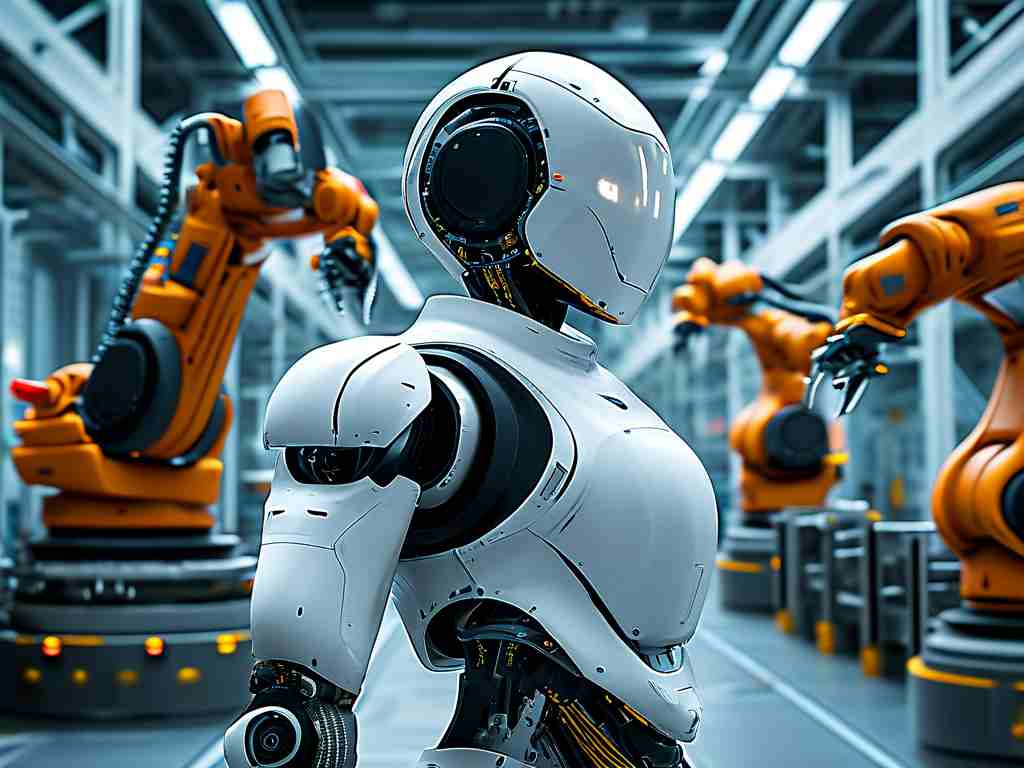

In recent years, Dongguan, a manufacturing powerhouse in southern China, has emerged as a leader in the development and deployment of inspection robot technology. These cutting-edge systems are transforming industrial operations by enhancing efficiency, reducing human error, and minimizing risks in hazardous environments. This article explores the latest advancements in Dongguan’s inspection robotics sector and their implications for modern industries.

The Rise of Inspection Robotics in Dongguan

Dongguan’s transition from traditional manufacturing to high-tech innovation has positioned it as a hub for robotics research. Local companies and startups are leveraging artificial intelligence (AI), computer vision, and IoT integration to create robots capable of performing complex inspections across diverse settings. For instance, the DG-InnoBot series, developed by a Dongguan-based tech firm, utilizes multi-sensor fusion to detect anomalies in machinery with 99.3% accuracy, outperforming manual inspections.

Key Technological Breakthroughs

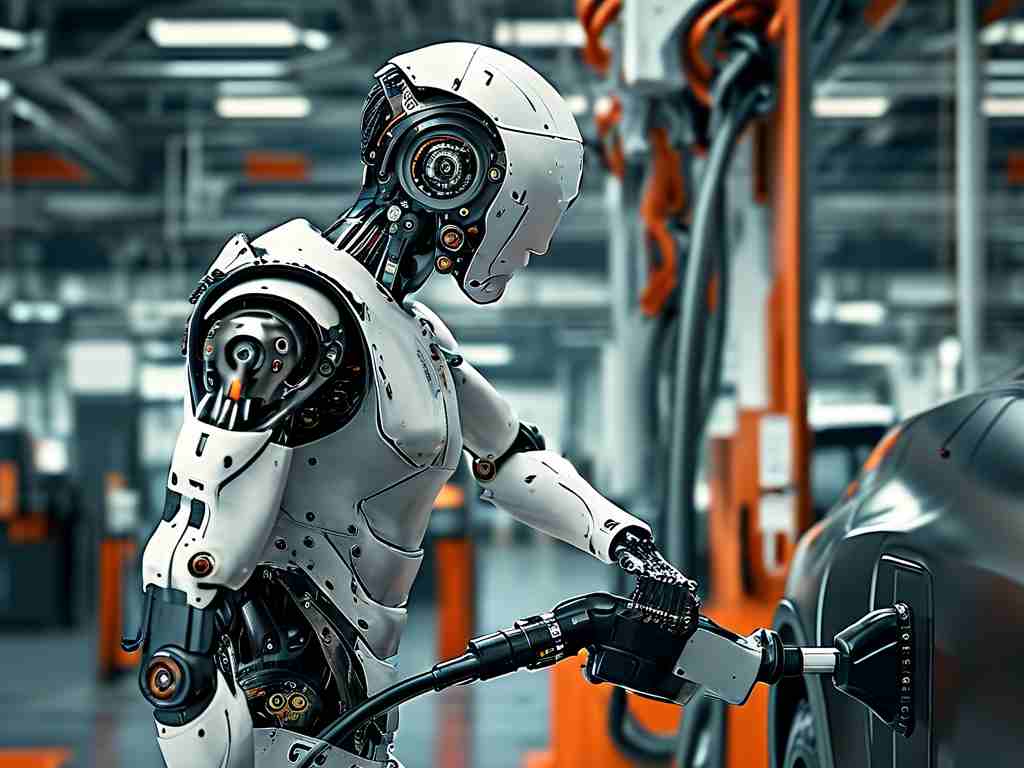

One standout innovation is the integration of 5G connectivity into inspection robots. This enables real-time data transmission and remote control, allowing operators to monitor equipment in chemical plants or power stations from safe distances. Additionally, adaptive algorithms enable these robots to “learn” from historical data, improving defect recognition over time. A case study at a Dongguan semiconductor factory revealed that AI-driven inspection robots reduced downtime by 42% within six months of implementation.

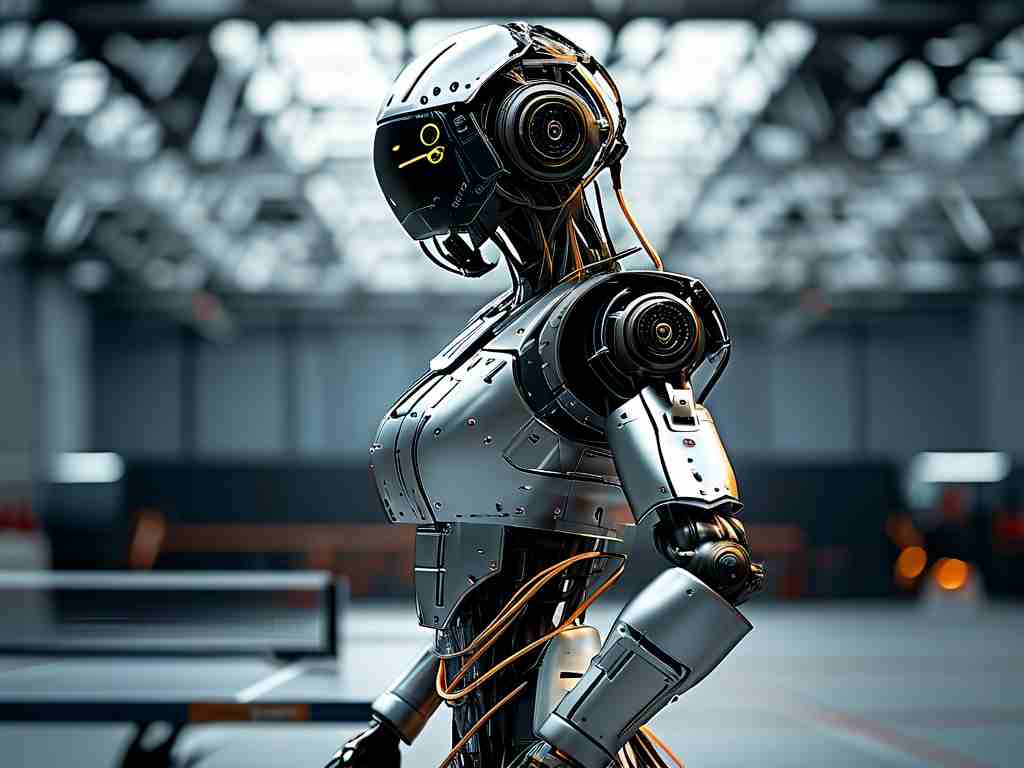

Applications Across Industries

- Manufacturing: Robots equipped with thermal cameras and ultrasonic sensors conduct 24/7 quality checks on assembly lines.

- Energy Sector: Autonomous drones inspect wind turbine blades and solar panel arrays, identifying micro-cracks invisible to the human eye.

- Logistics: Mobile robots with LiDAR mapping ensure warehouse safety by detecting obstacles and monitoring inventory conditions.

Challenges and Solutions

While the technology shows promise, challenges remain. Environmental factors like extreme temperatures and electromagnetic interference can affect sensor performance. Dongguan engineers are addressing this through ruggedized designs and redundant systems. For example, the newly launched StormGuard series features waterproof casings and failsafe navigation protocols tested in local electronics factories.

Economic and Safety Impacts

The adoption of inspection robots has yielded measurable benefits. A 2023 industry report estimates that Dongguan’s manufacturing sector saved over ¥800 million annually through reduced labor costs and accident-related expenses. Moreover, workplace injuries in high-risk inspection roles dropped by 67% year-on-year after robotic deployment.

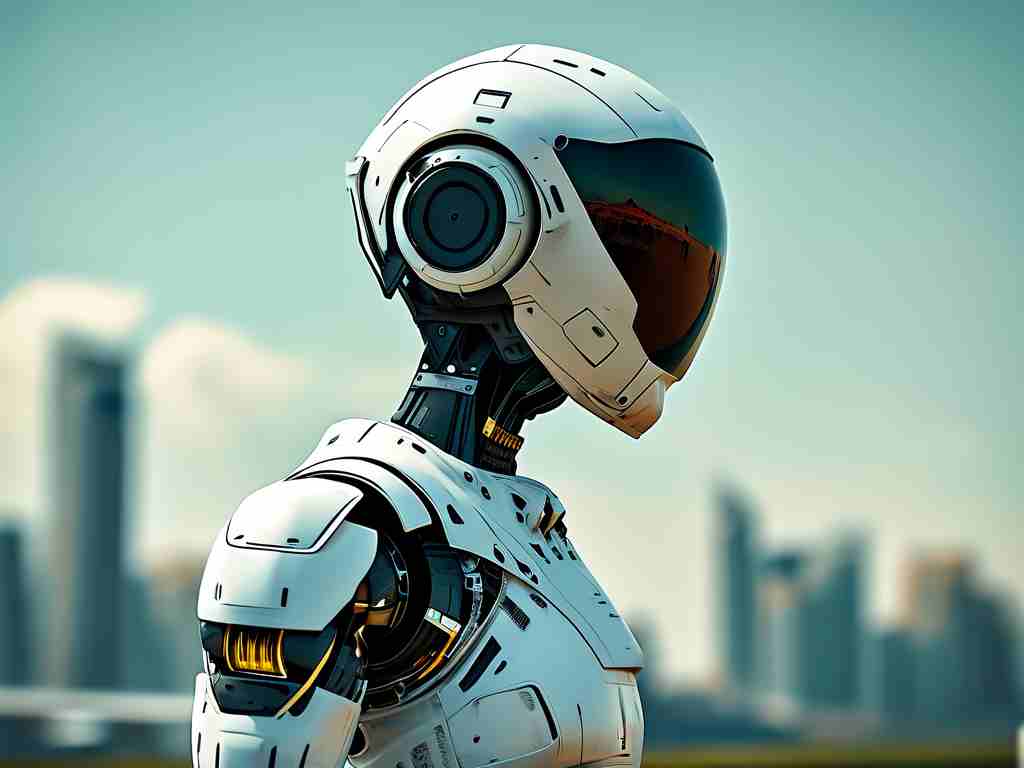

Future Outlook

Looking ahead, Dongguan’s R&D institutes are focusing on swarm robotics—coordinated fleets of small robots for large-scale inspections. Collaborative projects with universities aim to develop biodegradable inspection drones for environmental monitoring by 2025. As global demand for smart manufacturing grows, Dongguan’s expertise in inspection robotics positions it to become a key player in shaping Industry 4.0 standards.

In , Dongguan’s inspection robot technology represents a convergence of innovation and practicality. By continuing to bridge technological gaps and address industrial pain points, the region is setting new benchmarks for automated quality control worldwide.