In the heart of China’s technological innovation hub, Shanghai Yamaha Robotics has emerged as a trailblazer in advanced automation solutions. Combining decades of engineering expertise with cutting-edge artificial intelligence, the company is redefining efficiency and precision across industries. This article explores how Shanghai Yamaha Robotics is shaping the future of manufacturing, logistics, and beyond.

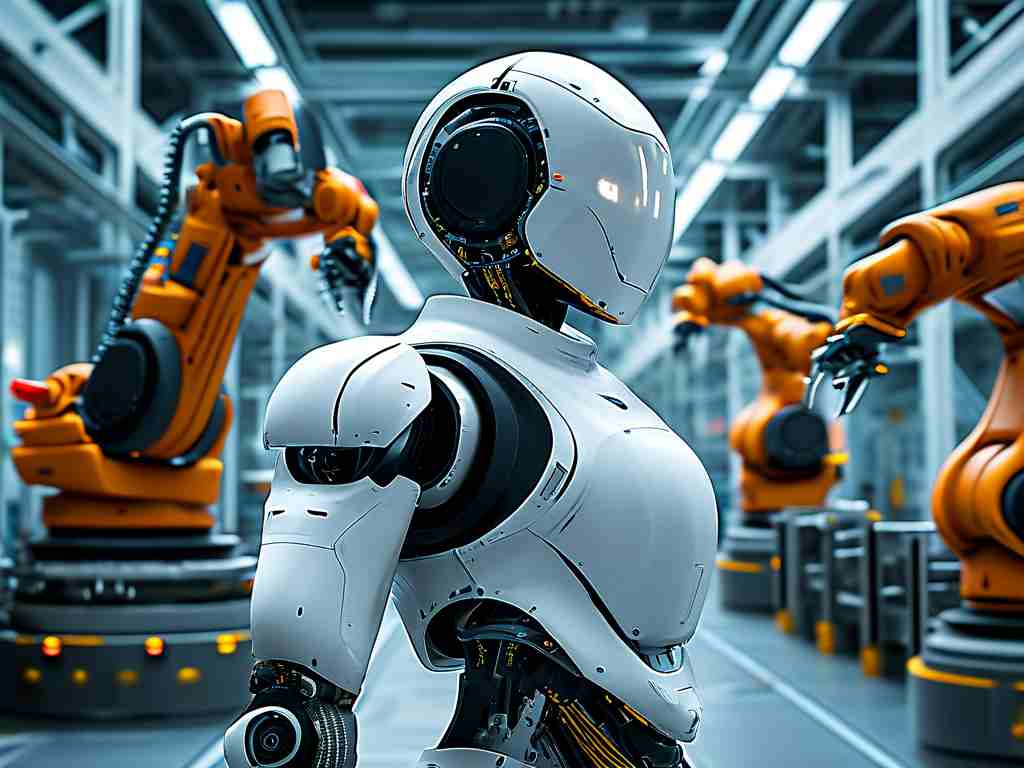

The Evolution of Precision Engineering

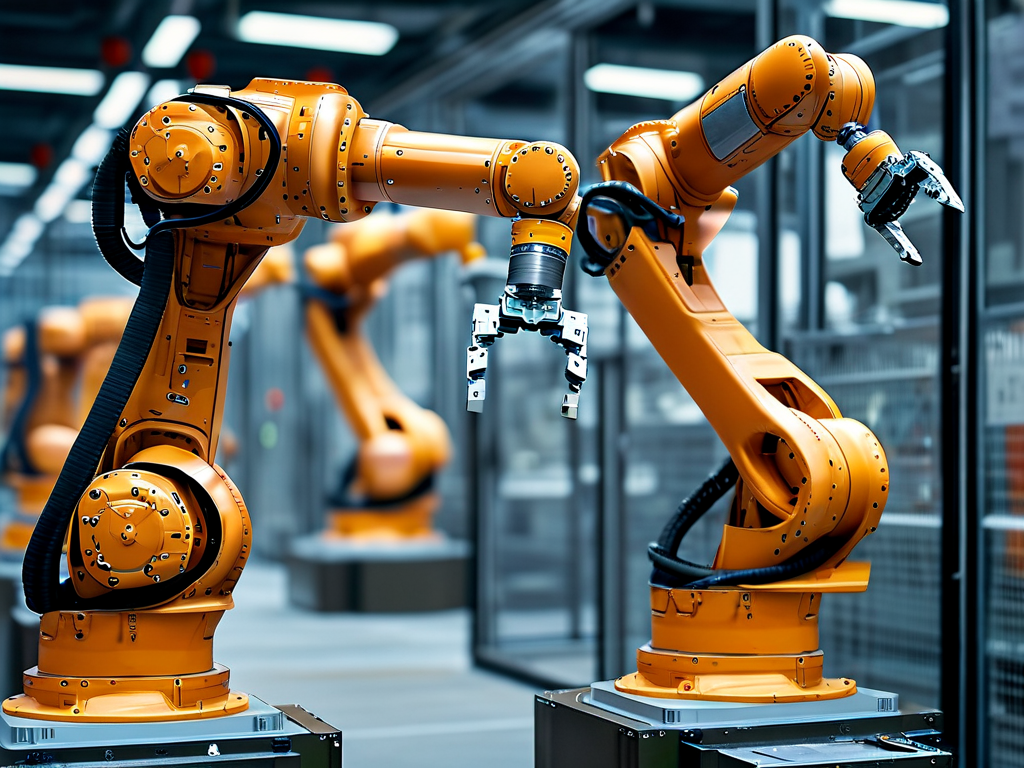

Shanghai Yamaha Robotics distinguishes itself through its proprietary motion control systems, which achieve micron-level accuracy in high-speed operations. Unlike conventional robotic arms, their adaptive algorithms enable real-time adjustments during tasks such as semiconductor assembly or automotive welding. For instance, a recent collaboration with a leading electric vehicle manufacturer demonstrated a 34% reduction in production errors after integrating Yamaha’s vision-guided robotic cells.

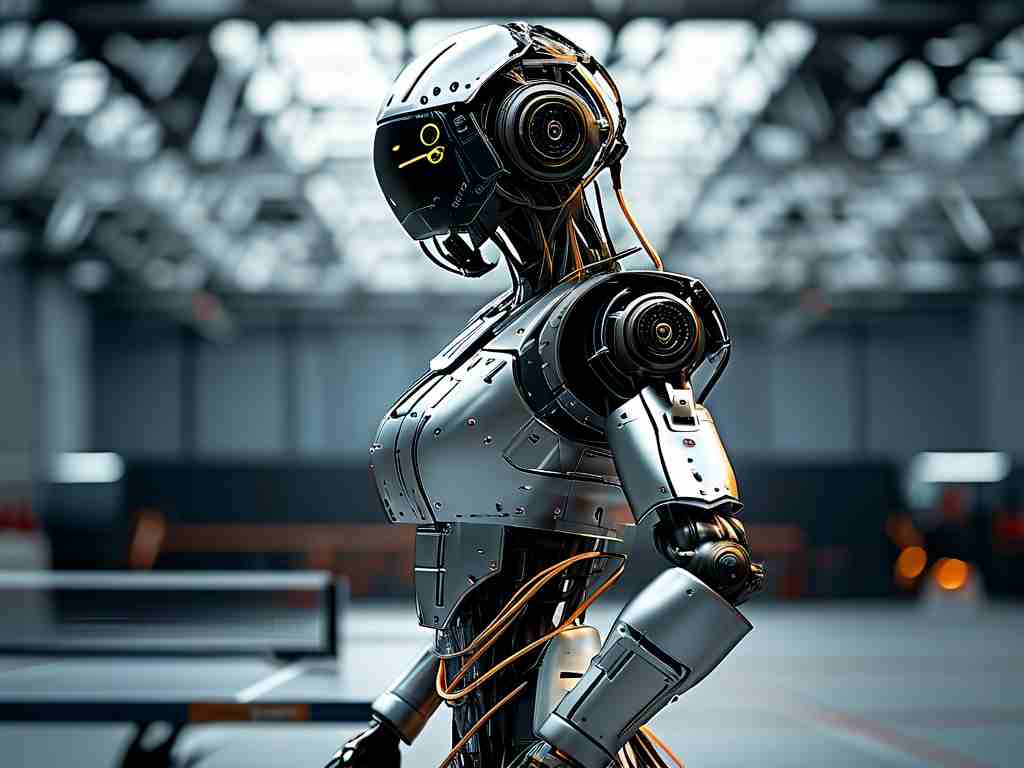

AI-Driven Collaborative Workflows

A hallmark of Shanghai Yamaha’s innovation lies in its collaborative robots (cobots) designed for seamless human-machine interaction. These cobots utilize multimodal sensors and machine learning to predict operator movements, enhancing workplace safety without compromising productivity. In pharmaceutical packaging lines, Yamaha’s cobots have reduced manual handling by 60% while maintaining stringent hygiene protocols—a critical advantage in post-pandemic manufacturing.

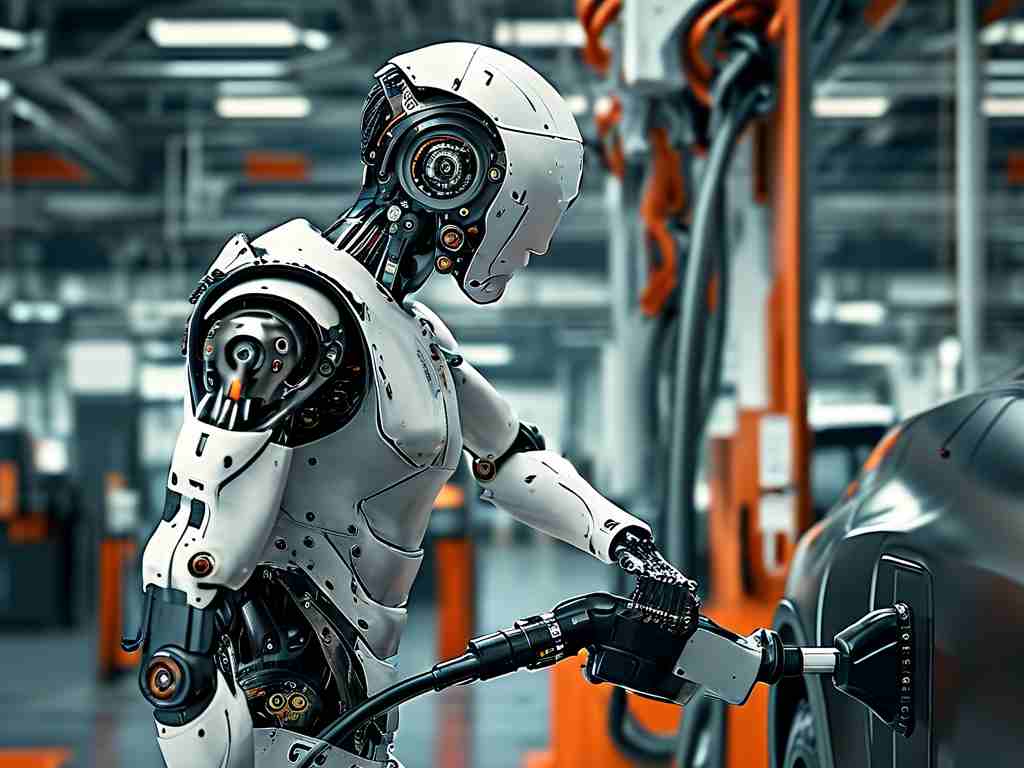

Customization for Industry 4.0 Challenges

Recognizing the diverse needs of modern enterprises, the company offers modular robotic platforms tailored to specific sectors. For logistics giants grappling with e-commerce demands, Yamaha’s autonomous mobile robots (AMRs) optimize warehouse navigation using LiDAR and 3D spatial mapping. One case study revealed a 50% faster order fulfillment rate for a Shanghai-based logistics firm deploying these AMRs alongside smart inventory systems.

Sustainability at the Core

Beyond operational efficiency, Shanghai Yamaha Robotics prioritizes energy-conscious designs. Their latest generation of servomotors consumes 22% less power than previous models, aligning with global carbon neutrality goals. Additionally, predictive maintenance algorithms extend equipment lifespans by up to 40%, reducing electronic waste—an increasingly vital consideration for environmentally conscious manufacturers.

Navigating Global Supply Chain Dynamics

The 2023 global chip shortage underscored the importance of agile production systems. Shanghai Yamaha responded by developing hybrid robotic workstations capable of rapid retooling for different components. This flexibility proved instrumental for electronics manufacturers in Shenzhen, enabling them to pivot between product lines within hours rather than days during supply chain disruptions.

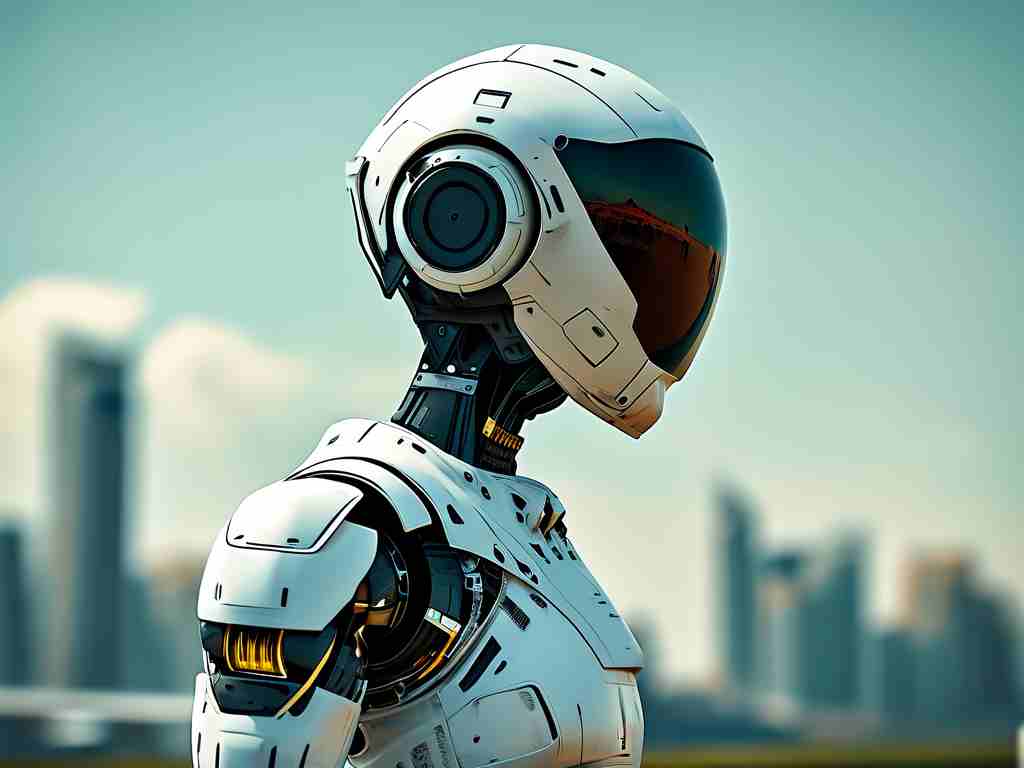

Future Horizons: From Factories to Smart Cities

Looking ahead, Shanghai Yamaha Robotics is expanding its scope beyond traditional industrial applications. Pilot projects in urban infrastructure include AI-powered inspection robots for subway maintenance and automated waste-sorting systems. These initiatives position the company at the forefront of China’s smart city ambitions, blending industrial robotics with civic innovation.

As industries worldwide grapple with labor shortages and sustainability mandates, Shanghai Yamaha Robotics offers a blueprint for intelligent automation. By continuously refining its technology stack and embracing cross-sector challenges, the firm not only addresses current manufacturing pain points but also lays the groundwork for next-generation automation ecosystems. Their journey underscores Shanghai’s growing role as a nexus of robotics innovation, where precision engineering meets transformative artificial intelligence.