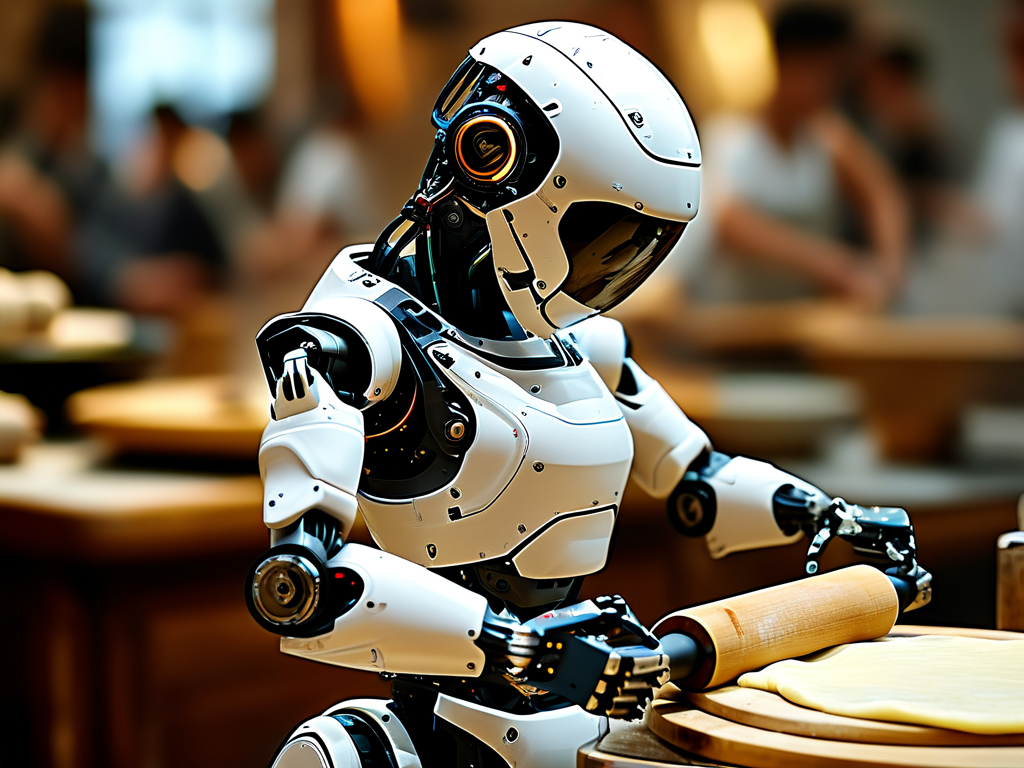

The integration of robotics into culinary processes has reached a groundbreaking milestone with the emergence of automated dough-rolling systems. This article explores the technical foundations and practical implementations of robotic dough manipulation, a field blending precision engineering with gastronomic artistry.

Mechanized Dough Handling Fundamentals

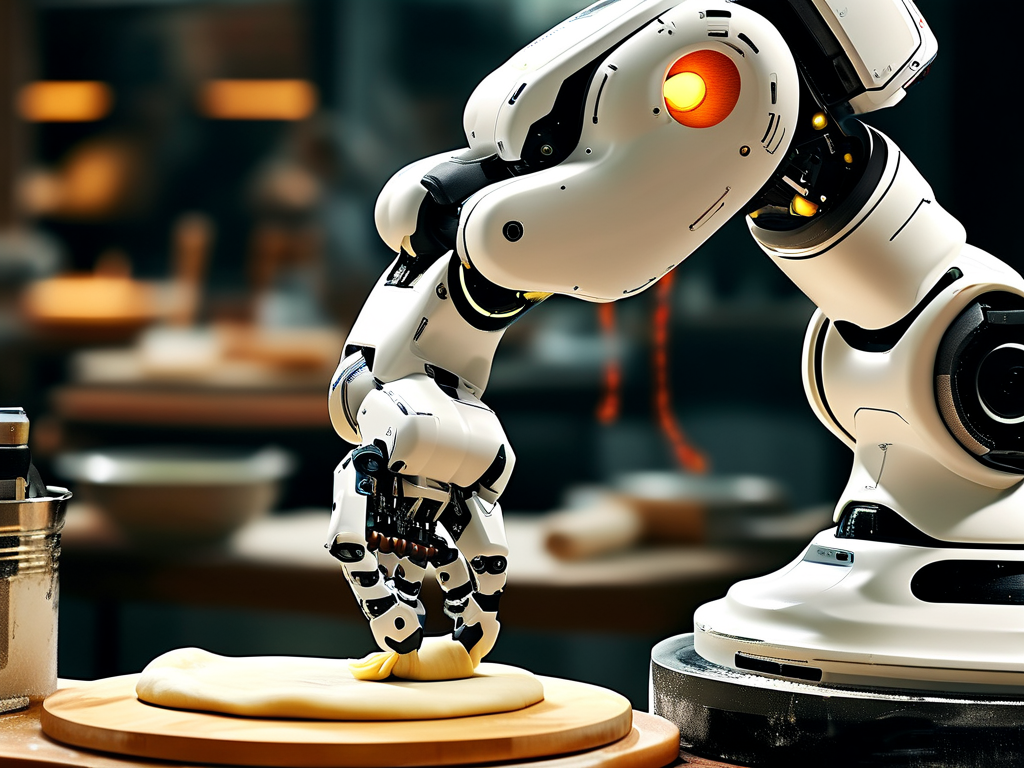

Modern dough-rolling robots employ multi-axis articulated arms equipped with specialized end-effectors. These custom-designed tools combine pressure-sensitive rollers with infrared surface scanners, enabling real-time thickness monitoring. The system's core innovation lies in its adaptive pressure control algorithm, which automatically adjusts rolling intensity based on dough elasticity measurements taken through embedded torque sensors.

A critical challenge engineers have overcome involves replicating the nuanced "feel" of human dough manipulation. Advanced models now incorporate machine learning frameworks trained on thousands of manual rolling patterns. This allows robots to mimic regional dough preparation techniques – from the paper-thin wrappers of Cantonese dim sum to the layered textures of French puff pastry.

Sensor Fusion Architecture

The technological backbone comprises three integrated subsystems:

- Viscoelasticity measurement module using ultrasonic wave propagation analysis

- Thermal regulation unit maintaining optimal dough temperature (±0.5°C)

- Surface texture recognition through hyperspectral imaging

This sensor fusion approach enables dynamic adjustments during operation. For instance, when detecting uneven gluten development, the system initiates compensatory rolling patterns while automatically activating moisture control mechanisms.

Industrial Implementation Cases

Leading food manufacturers have adopted these systems for mass production scaling. A Beijing-based dumpling factory reported 40% throughput increase after installing dough-rolling bots, while reducing material waste by 18%. Commercial pizza chains utilize the technology for consistent crust production, with one Neapolitan-style franchise achieving 98% thickness uniformity across 2,000 daily bases.

Technical Limitations and Solutions

Current systems face challenges with high-hydration doughs (above 75% water content). Recent prototypes address this through vacuum-assisted rolling chambers that prevent sticking while preserving moisture levels. Another development involves hybrid human-robot stations where automated systems handle bulk processing, with chefs performing final manual adjustments for artisanal products.

Future Development Trajectory

Next-generation models aim to integrate molecular-level analysis using Raman spectroscopy for real-time ingredient quality assessment. Researchers are also experimenting with quantum computing algorithms to predict dough behavior under varying environmental conditions. The ultimate goal involves creating fully autonomous "dough evolution" systems that can adapt recipes based on flour protein content and atmospheric humidity.

The convergence of robotics and culinary science continues to redefine food preparation standards. As these technologies mature, they promise to enhance both industrial-scale production and precision-focused artisanal crafting, while preserving the irreplaceable human touch in final culinary presentation.