The relationship between electric arc technology and robotics has become an intriguing topic in modern industrial discussions. While both fields represent advanced technological domains, their fundamental principles and applications reveal distinct characteristics that warrant careful examination.

Understanding Electric Arcs

An electric arc is a visible plasma discharge caused by electrical current ionizing gases. This phenomenon, first documented in the early 19th century, has evolved into critical industrial applications such as welding, metal cutting, and circuit breakers. The intense heat generated by arcs—reaching up to 20,000°C—enables precision material processing that mechanical tools struggle to achieve.

Robotics: A Multidisciplinary Field

Modern robotics integrates mechanics, electronics, and artificial intelligence to create autonomous or semi-autonomous systems. Industrial robots excel in repetitive tasks like assembly line operations, while advanced models incorporate machine learning for adaptive decision-making. The core distinction lies in robotics' focus on programmable motion and environmental interaction.

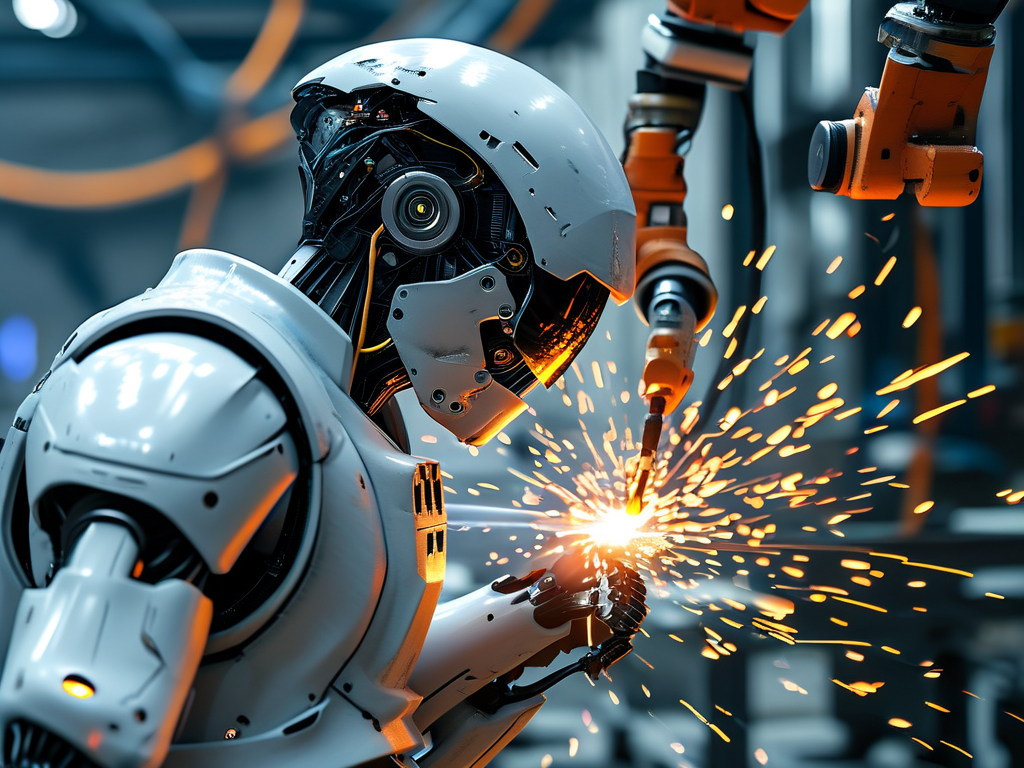

Intersections in Industrial Applications

The connection between arcs and robotics emerges in specialized equipment like arc welding robots. These systems combine robotic manipulators with arc-based tools to perform complex welding tasks in automotive manufacturing. However, the arc itself remains a controlled energy source rather than an intelligent component. Engineers program robots to regulate arc parameters (voltage, current, gas flow), but the arc lacks the decision-making algorithms inherent to robotic systems.

Technical Divergences

- Control Mechanisms: Robots rely on software-driven feedback loops, whereas arc behavior depends on physics principles like ionization and thermal dynamics.

- Adaptive Capacity: Modern robots can adjust operations based on sensor data, while arcs require external control systems to maintain stability.

- Energy Utilization: Arcs convert electrical energy to thermal/light energy, contrasting with robots' mechanical energy conversion.

Emerging Hybrid Technologies

Recent advancements show promising integrations:

- Plasma arc robots for deep-sea pipeline repair

- AI-guided arc systems for precision micro-welding

- Autonomous drones using arc discharges for aerial metal cutting

These innovations blend robotic mobility with arc-based processing, yet maintain clear functional boundaries between the two technologies.

Future Development Trajectories

Industry experts predict three key trends:

- Enhanced arc control through machine learning algorithms

- Development of self-regulating arc systems mimicking basic robotic functions

- Miniaturized arc technologies for medical robotics applications

While these developments suggest convergence, the fundamental distinction remains: arcs serve as energy application tools, whereas robotics encompasses complete electromechanical systems with intelligent control capabilities.

Electric arc technology and robotics represent complementary rather than hierarchical domains. Their collaboration in advanced manufacturing demonstrates how specialized technologies can synergize without losing individual identity. As Industry 4.0 progresses, understanding these boundaries becomes crucial for optimizing technological integration while respecting each field's unique contributions.