The evolution of miniature robotics has revolutionized industries ranging from healthcare to manufacturing. At its core, small robot technology relies on a blend of mechanical engineering, embedded systems, and adaptive algorithms. This article explores the foundational principles driving these compact machines, emphasizing their design constraints, operational frameworks, and real-world applications.

Mechanical Design and Mobility

Miniature robots face unique challenges due to their size limitations. Unlike larger counterparts, they require lightweight materials such as carbon-fiber composites or shape-memory alloys to maintain structural integrity while minimizing energy consumption. Mobility mechanisms vary: some models use micro-wheels with torque-optimized motors, while others employ bio-inspired designs like insectoid legs or flagellar propulsion for fluid environments. A notable example is the use of piezoelectric actuators in medical microbots, which convert electrical signals into precise mechanical movements for navigating blood vessels.

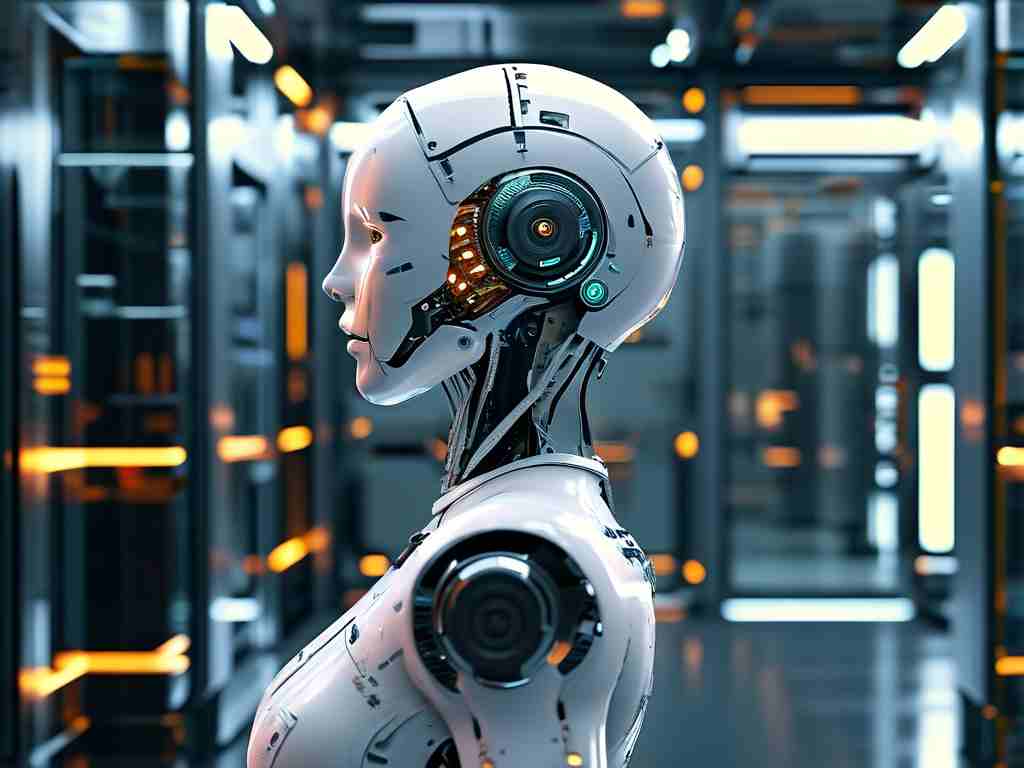

Sensory Integration

Effective environmental interaction depends on advanced sensor arrays. Infrared proximity sensors, MEMS-based accelerometers, and capacitive touch detectors enable real-time spatial awareness. For instance, industrial inspection bots often integrate thermal imaging modules to identify equipment anomalies. Recent advancements include hybrid systems combining LiDAR for 3D mapping with ultrasonic sensors to operate in low-visibility conditions. These components feed data to centralized processing units, where edge computing reduces latency by filtering noise locally before transmitting critical information.

Control Systems and Autonomy

The brain of a small robot typically involves a microcontroller running real-time operating systems (RTOS). Algorithms such as PID controllers adjust motor speeds based on sensor feedback, while machine learning models enable adaptive behaviors. Swarm robotics introduces another layer of complexity, requiring decentralized coordination protocols. Researchers at MIT recently demonstrated a fleet of coin-sized robots that collaboratively assemble structures using Bluetooth Low Energy (BLE) mesh networking and consensus algorithms.

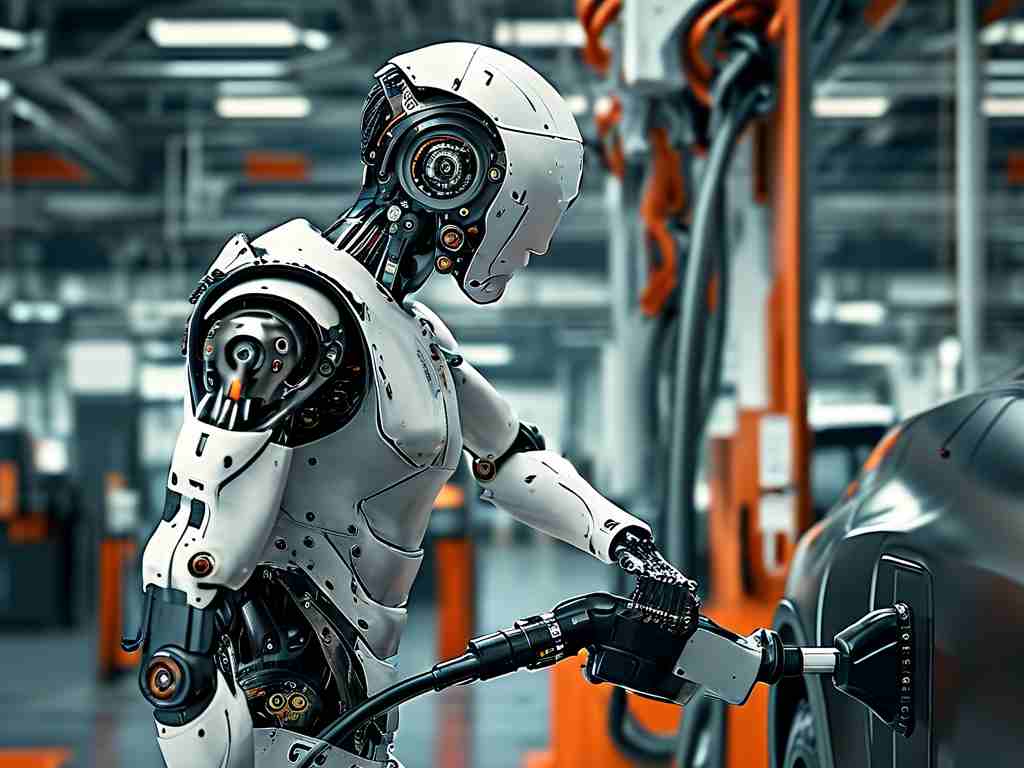

Power Management Challenges

Energy efficiency remains a bottleneck for sustained operation. Many miniature robots rely on lithium-polymer batteries with energy densities up to 250 Wh/kg, but frequent recharging limits autonomy. Innovations like wireless inductive charging pads or energy-harvesting systems (e.g., solar cells or kinetic generators) aim to address this. A breakthrough came in 2023, when a team at Stanford unveiled a 5mm robot powered by supercapacitors recharged via ambient radio frequencies, achieving 12-hour continuous operation.

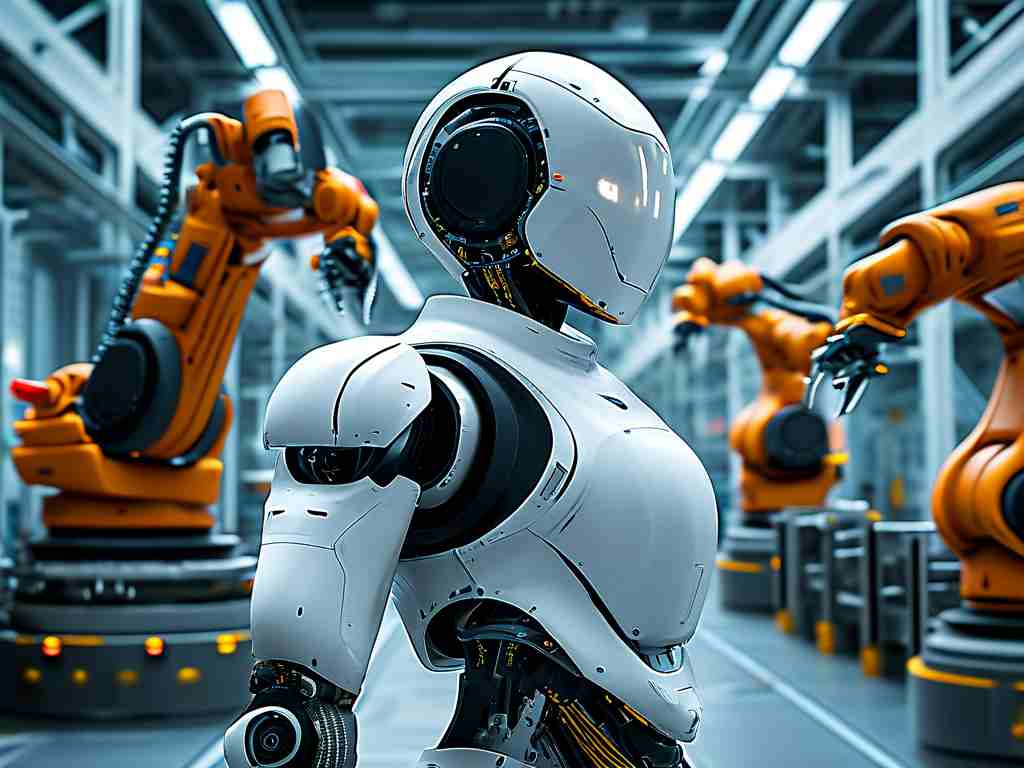

Applications Across Industries

In healthcare, sub-gram robots perform targeted drug delivery or biopsy sampling with sub-millimeter precision. Agricultural microbots monitor soil pH and moisture levels, relaying data to irrigation systems. Consumer electronics benefit, too—think of self-cleaning camera lenses using nano-robotic brushes. Defense sectors deploy stealth reconnaissance bots equipped with gas sensors and encrypted communication modules.

Future Directions

Emerging trends focus on material science and AI integration. Graphene-based circuits could enhance processing power without increasing size, while neuromorphic chips mimic human neural networks for decision-making. Another frontier is soft robotics, where silicone-based actuators enable safer human-robot interaction. As quantum computing matures, it may solve optimization problems currently limiting swarm intelligence scalability.

In summary, the principles underpinning small robot technology intertwine engineering ingenuity with computational sophistication. By overcoming size-related constraints through innovative design and smart resource allocation, these machines continue to expand the boundaries of automation.