Nestled in China’s southeastern tech corridor, Fuzhou has emerged as a hub for specialized embedded development services. Businesses across industries increasingly seek tailored embedded solutions to optimize operations, and Fuzhou-based developers are answering this demand with cutting-edge expertise. This article explores how custom embedded development in Fuzhou addresses modern technological challenges while maintaining cost efficiency and scalability.

The Rise of Embedded Systems in Industrial Applications

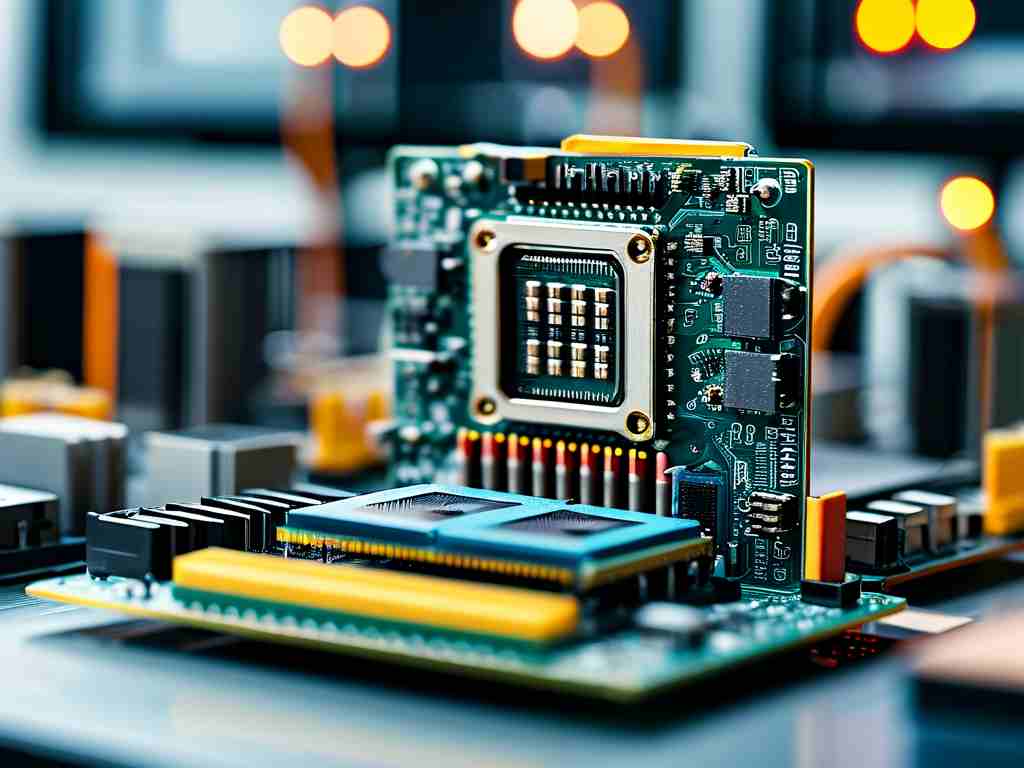

Embedded systems form the backbone of smart devices, IoT networks, and industrial automation. Unlike generic software, these systems require precise hardware-software integration. Fuzhou’s engineering teams excel in designing customized embedded platforms for sectors like manufacturing, healthcare, and logistics. For instance, a local developer recently created a real-time monitoring system for textile machinery, reducing downtime by 40% through predictive maintenance algorithms.

One distinguishing feature of Fuzhou’s approach is its focus on modular architecture. Developers often use code snippets like:

void sensor_data_handler() {

// Custom logic for industrial sensor fusion

process_raw_data();

transmit_via_LoRaWAN();

} This flexibility allows clients to update functionalities without overhauling entire systems.

Balancing Performance and Power Efficiency

A critical challenge in embedded development is optimizing power consumption without compromising processing capabilities. Fuzhou engineers leverage RISC-V architectures and low-power SoC designs to achieve this balance. A case in point is a smart agriculture project where solar-powered soil sensors operate for 18 months on a single charge while transmitting data hourly.

The city’s developers also prioritize secure communication protocols. With cyber threats on the rise, custom solutions now integrate hardware-based encryption modules. One automotive client reported a 70% reduction in vulnerability incidents after migrating to a Fuzhou-developed ECU (Electronic Control Unit) with embedded TLS 1.3 support.

Cross-Industry Adaptation Strategies

What sets Fuzhou’s embedded specialists apart is their adaptive methodology. Rather than offering one-size-fits-all products, teams conduct thorough needs assessments. For a marine navigation startup, this meant developing a saltwater-resistant embedded controller with machine learning-based anomaly detection:

if (sensor_readings > threshold) {

trigger_self_cleaning_routine();

log_incident(SD_CARD);

} Such contextual adaptations explain why 85% of clients report improved operational longevity after implementing these bespoke systems.

Collaboration with Global Standards

Fuzhou’s embedded ecosystem thrives on collaboration. Many firms hold certifications like ISO 26262 for automotive functional safety and IEC 62304 for medical device software. This compliance enables seamless integration with international supply chains. A German robotics manufacturer recently partnered with a Fuzhou developer to create a dual-certified (CE/FCC) motion control system, cutting time-to-market by six months.

Future-Proofing Through R&D Investment

Local universities and tech parks drive innovation through joint R&D initiatives. The Fuzhou Embedded Technology Institute, established in 2021, has filed 23 patents in edge computing and AI-embedded applications. Ongoing projects include neural network accelerators for real-time video analytics and energy-harvesting sensor nodes for smart cities.

As 5G and AI reshape embedded landscapes, Fuzhou’s developers continue evolving. Their commitment to customization—whether refining motor control algorithms for e-bikes or designing fail-safe systems for medical ventilators—positions the city as a global contender in smart hardware solutions. Clients gain not just code, but strategic partners invested in their long-term technological resilience.