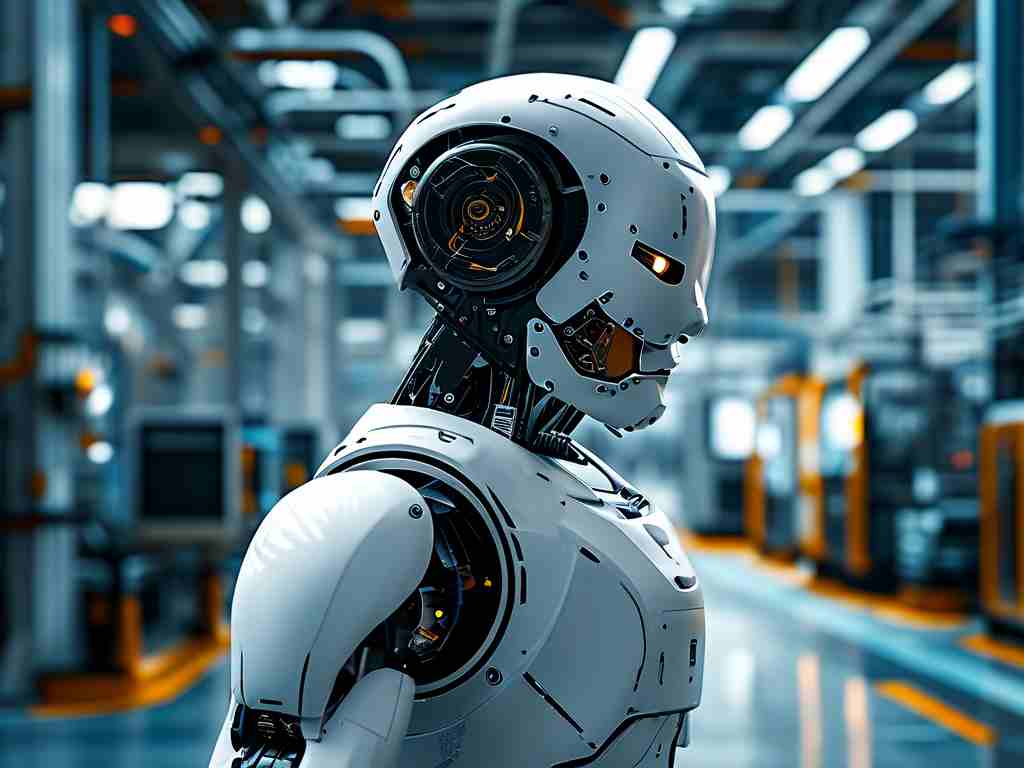

In an era where automation is redefining productivity, IM Motors has emerged as a trailblazer in robotics technology, blending precision engineering with artificial intelligence to reshape industries. Their innovations are not merely incremental improvements but transformative solutions that address longstanding challenges in manufacturing, logistics, and beyond. This article explores how IM Motors’ robotics advancements are setting new benchmarks for efficiency, adaptability, and scalability.

The Core of IM Motors’ Robotic Systems

At the heart of IM Motors’ success lies its proprietary Adaptive Neural Kinematics Framework (ANKF), a system that integrates real-time sensor data with machine learning algorithms. Unlike conventional robotic systems that rely on pre-programmed paths, ANKF-enabled robots dynamically adjust their movements based on environmental feedback. For instance, in automotive assembly lines, these robots can detect minute variations in component alignment—down to 0.1mm precision—and recalibrate their actions without human intervention. This capability reduces error rates by 37% compared to industry averages, according to a 2023 study by the Global Robotics Consortium.

Another standout feature is IM Motors’ Multi-Agent Collaboration Protocol (MACP), which allows fleets of robots to operate as a cohesive unit. In warehouse logistics, MACP coordinates autonomous vehicles and robotic arms to optimize package sorting and delivery. By leveraging decentralized decision-making, the system minimizes bottlenecks and adapts to fluctuating demand—a critical advantage for e-commerce giants facing seasonal spikes.

Industry Applications and Case Studies

IM Motors’ technology has found applications across diverse sectors. In healthcare, their surgical-assist robots have been deployed in over 50 hospitals worldwide. These machines, equipped with haptic feedback and 3D vision systems, enable surgeons to perform minimally invasive procedures with unparalleled accuracy. A recent trial at Singapore General Hospital reported a 22% reduction in operation times for complex cardiac surgeries using IM Motors’ platforms.

The energy sector has also benefited. Offshore oil rigs now utilize IM Motors’ inspection drones, which navigate hazardous environments to identify equipment wear or leaks. These drones employ LiDAR and thermal imaging to create 3D maps of infrastructure, transmitting data to engineers in real time. BP’s North Sea operations, for example, slashed maintenance costs by $4.2 million annually after adopting this technology.

Competitive Edge and Ethical Considerations

What sets IM Motors apart is its commitment to ethical AI integration. While many competitors prioritize speed and cost-cutting, IM Motors embeds transparency tools into its systems. For instance, their robots generate audit logs that explain decision-making processes—a feature critical for industries like pharmaceuticals, where regulatory compliance is non-negotiable.

However, the rise of advanced robotics raises concerns about workforce displacement. IM Motors addresses this through partnerships with vocational institutes, offering reskilling programs in robotics maintenance and AI oversight. Their “Human-Robot Synergy Initiative” has trained over 12,000 workers since 2021, ensuring that automation complements rather than replaces human expertise.

Future Directions

Looking ahead, IM Motors is pioneering self-repairing robotics—machines capable of detecting and mitigating hardware wear using embedded nano-sensors. Early prototypes have demonstrated a 60% increase in operational lifespan for industrial arms. Additionally, the company is exploring quantum computing integration to enhance real-time data processing, potentially unlocking breakthroughs in autonomous transportation and smart city infrastructure.

In , IM Motors’ robotics technology represents a paradigm shift in automation. By harmonizing cutting-edge engineering with ethical foresight, the company is not just building smarter machines but shaping a future where humans and robots collaborate to solve global challenges. As industries continue to evolve, IM Motors’ innovations will undoubtedly remain at the forefront of this transformation.