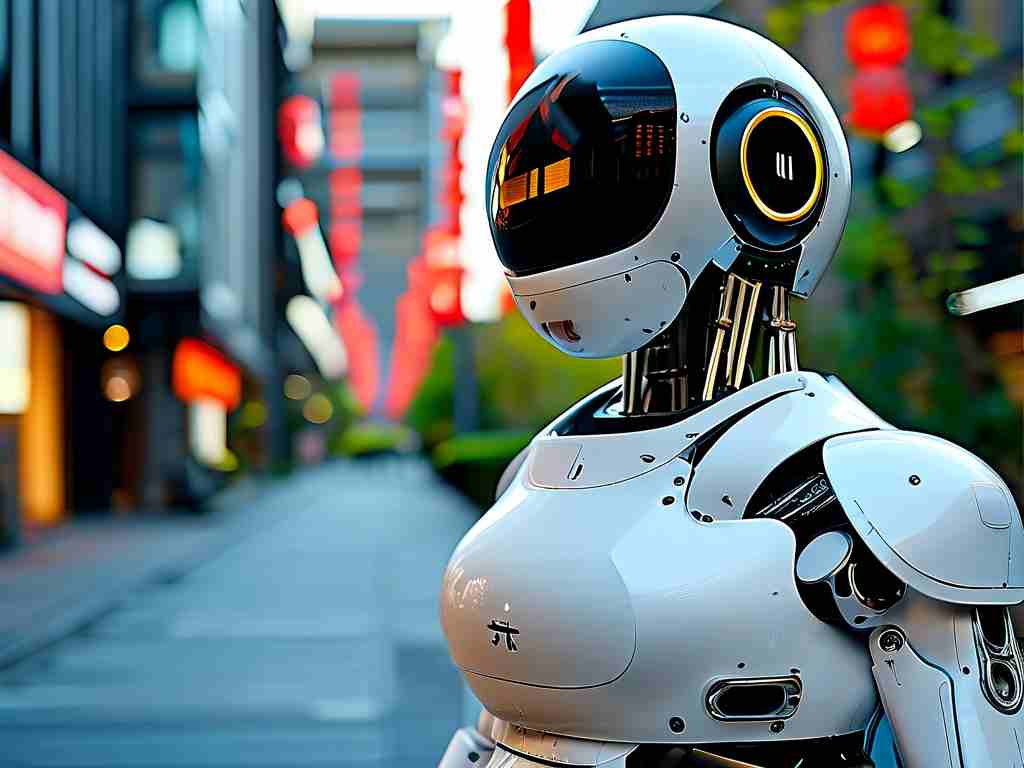

In the rapidly evolving landscape of industrial automation, RunChuan Technology Robotics has emerged as a pioneering force, driving transformative changes across manufacturing, logistics, and precision engineering sectors. Founded on the principle of integrating artificial intelligence with advanced mechanical systems, the company has redefined operational efficiency while addressing critical challenges in modern production environments.

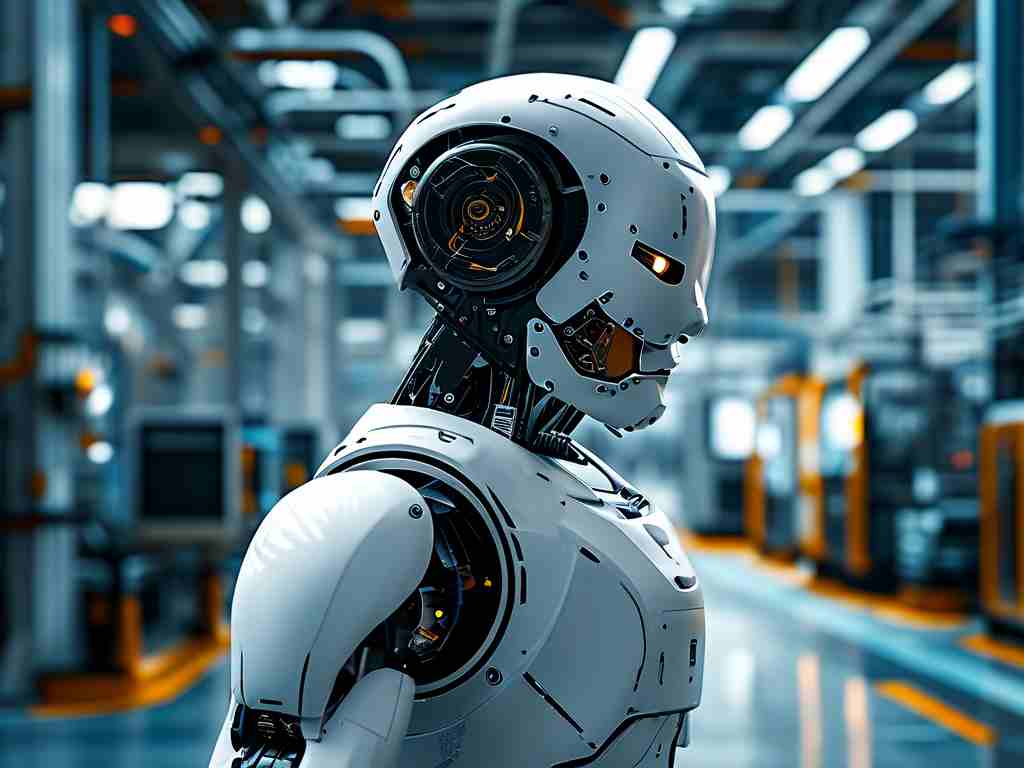

At the core of RunChuan's innovation lies its proprietary adaptive control framework, which combines real-time data analytics with machine learning algorithms. Unlike conventional robotic systems that rely on pre-programmed instructions, RunChuan's robots utilize dynamic path optimization to adjust operations based on environmental variables. For instance, in automotive assembly lines, their robotic arms demonstrate millimeter-level accuracy while autonomously compensating for material inconsistencies or equipment vibrations—a capability proven to reduce production errors by 38% in partnered factories.

The company's recent collaboration with renewable energy manufacturers highlights its versatility. Solar panel installations, traditionally labor-intensive and prone to quality variations, now leverage RunChuan's mobile robotic platforms equipped with hyperspectral imaging. These units autonomously inspect photovoltaic cells for microcracks during assembly, achieving a 99.7% defect detection rate while operating 60% faster than human technicians. Such advancements not only accelerate production cycles but also minimize resource waste—a critical factor in sustainable manufacturing.

RunChuan's impact extends beyond hardware. Its cloud-based platform, RC-Synergy, enables cross-facility coordination through decentralized decision-making protocols. In one documented case, three separate production plants using this system synchronized their inventory management and machine maintenance schedules, reducing downtime by 22% and cutting energy consumption by 15% within six months. This software-hardware integration exemplifies the company's commitment to holistic automation solutions.

Challenges persist in human-robot collaboration, particularly in industries requiring delicate manual operations. RunChuan addresses this through its patented tactile feedback interface, which allows workers to "guide" robots using intuitive hand gestures while maintaining safety protocols. Early adopters in precision electronics assembly report a 40% reduction in training time for hybrid workstations, coupled with a 28% improvement in task completion speed.

Looking ahead, RunChuan is investing in quantum computing-resistant encryption for its industrial IoT networks and exploring swarm robotics for large-scale agricultural applications. As global industries face mounting pressure to balance productivity with sustainability, RunChuan Technology Robotics stands positioned at the forefront of intelligent automation—not merely as equipment providers, but as architects of next-generation industrial ecosystems.