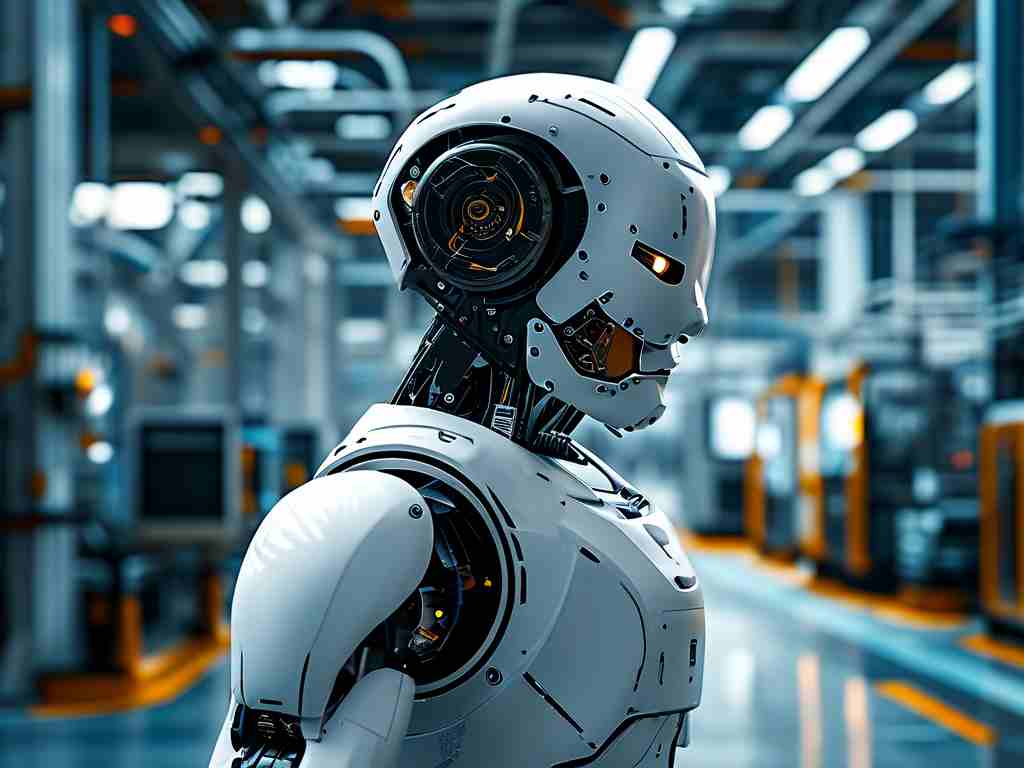

In the evolving landscape of industrial automation, Pinggu Micro-Electrostatic Robotics has emerged as a groundbreaking innovation, blending advanced electrostatic principles with cutting-edge robotic systems. This technology is redefining precision tasks across industries, from semiconductor manufacturing to biomedical research, offering unparalleled control and efficiency.

The Science Behind the Innovation

At its core, Pinggu's micro-electrostatic technology leverages controlled electrostatic charges to manipulate objects at microscopic scales. Unlike traditional vacuum-based or mechanical grippers, this approach eliminates physical contact, reducing contamination risks and minimizing damage to delicate materials. The robots utilize adaptive charge modulation, enabling them to handle diverse materials – from conductive metals to fragile polymer films – with sub-micron accuracy.

Industrial Applications

-

Electronics Manufacturing

In semiconductor fabrication, these robots excel at positioning microchips and circuit components. A major Asian chipmaker reported a 40% reduction in defect rates after integrating Pinggu systems, attributed to the non-contact handling of silicon wafers. -

Pharmaceutical Research

Laboratories employ these robots for assembling drug-delivery microdevices. The electrostatic control allows precise placement of bioactive compounds without compromising sterility, accelerating development cycles for next-generation medications. -

Advanced Materials Development

Graphene researchers now use Pinggu robots to stack atom-thin layers, achieving cleaner interfaces compared to conventional methods. This breakthrough has enabled commercial production of high-performance flexible displays.

Technical Advantages Over Competing Systems

Pinggu's proprietary algorithms dynamically adjust electrostatic fields based on real-time sensor data, overcoming traditional limitations of humidity sensitivity and charge decay. Recent field tests demonstrated 99.2% positioning accuracy in environments with 85% relative humidity – a critical advancement for tropical manufacturing hubs.

The system's modular design allows seamless integration with existing production lines. A case study at a German automotive supplier showed full deployment within 72 hours, requiring only standard 220V power and Ethernet connectivity.

Sustainability Impact

By eliminating consumables like suction cups and reducing energy consumption by 60% compared to pneumatic systems, Pinggu robots align with global decarbonization goals. The technology has received certification from the International Clean Technology Association (ICTA) for its near-zero particulate emissions.

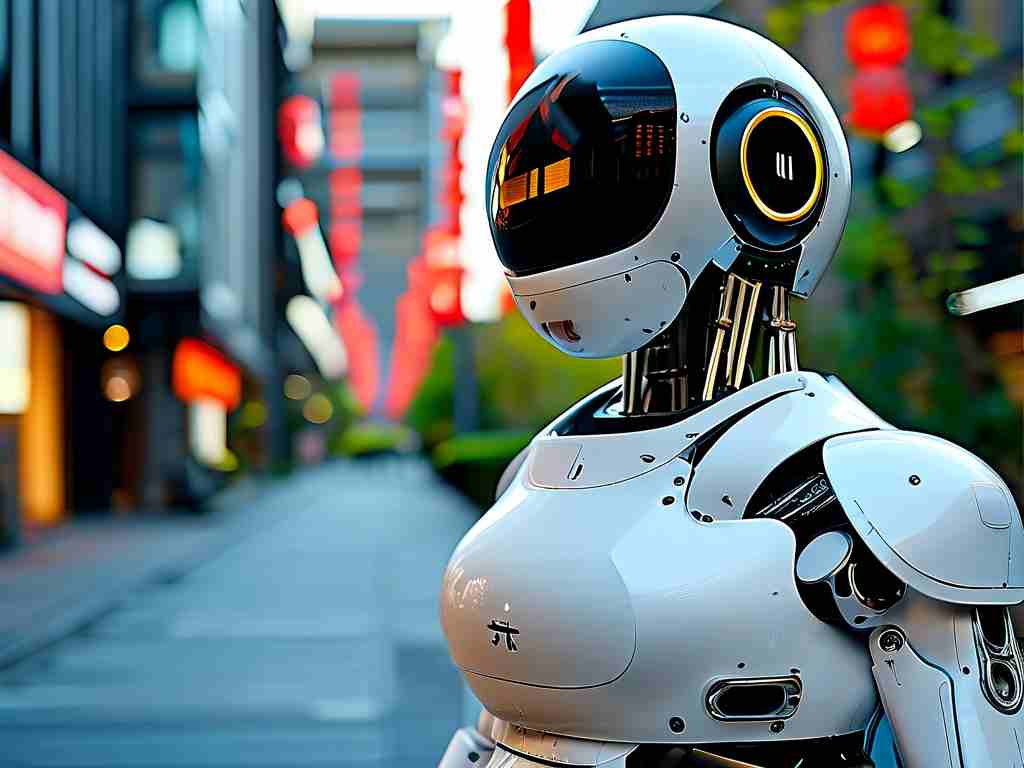

Future Roadmap

Pinggu's R&D team recently unveiled prototypes incorporating AI-driven predictive maintenance. Early adopters in the aerospace sector are testing these models for satellite component assembly, where reliability is paramount. The company plans to launch a nano-scale version in 2025, targeting quantum computing hardware production.

Challenges and Solutions

While initial costs remain higher than conventional robots (approximately $120,000 per unit), lifecycle analyses show 300% ROI over five years through reduced waste and downtime. Financing partnerships with major industrial banks are making the technology accessible to SMEs.

Regulatory compliance has been streamlined through collaborations with standardization bodies. The Pinggu ESD-9000 series became the first electrostatic robotics line to receive ISO Class 1 cleanroom certification in 2023.

As industries push the boundaries of miniaturization and precision, Pinggu Micro-Electrostatic Robotics stands at the forefront of this silent revolution. With ongoing advancements in material science and AI integration, these systems are poised to become indispensable tools in high-tech manufacturing – transforming how we build everything from smartphones to life-saving medical devices.