The evolution of robotics has transformed industries ranging from manufacturing to healthcare, with robotics assembly technology standing at the core of this revolution. This field combines mechanical engineering, software development, and precision automation to create systems capable of performing complex tasks with minimal human intervention. But what exactly defines robotics assembly technology, and why does it matter in today’s tech-driven world?

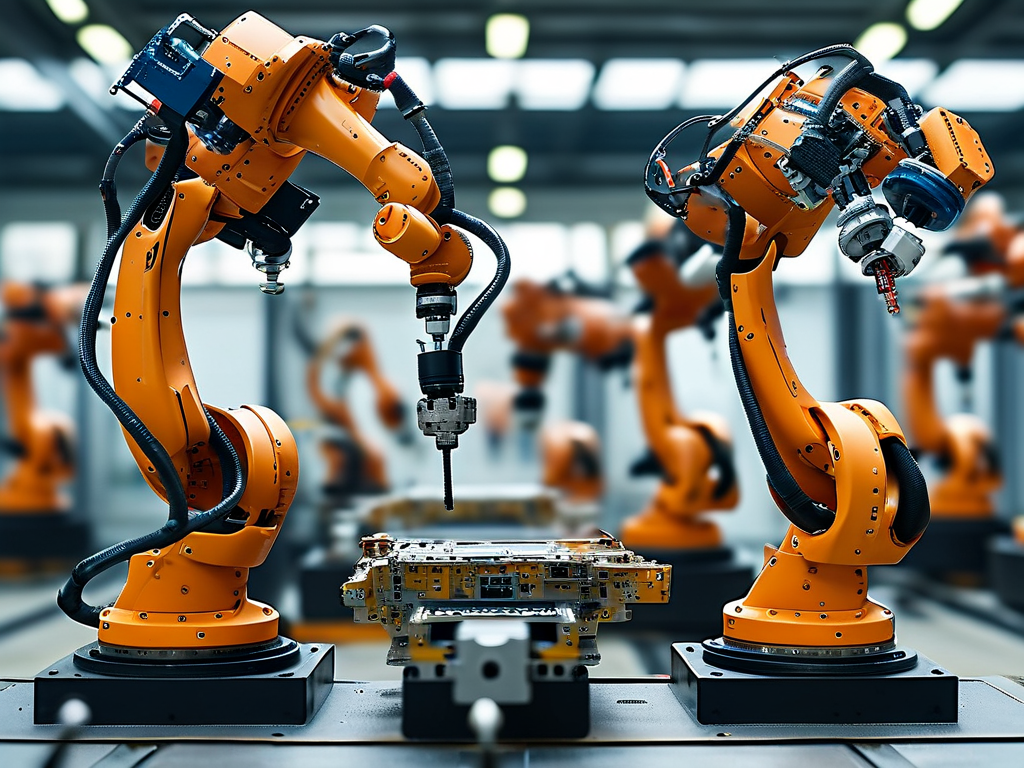

At its essence, robotics assembly technology refers to the methods, tools, and frameworks used to design, build, and program robots for specific operational workflows. Unlike general-purpose robots, assembly-focused systems are tailored for repetitive, high-accuracy tasks such as assembling electronic components, welding automotive parts, or packaging consumer goods. These systems rely on a synergy of hardware components—like actuators, sensors, and end-effectors—and advanced software algorithms that enable decision-making and adaptability.

One critical aspect of robotics assembly is modular design. Modern robotic systems often use interchangeable components, allowing engineers to customize configurations based on task requirements. For example, a robot designed for circuit board assembly might feature ultra-precise grippers and vision systems, while one built for heavy machinery assembly could prioritize torque-resistant joints and collision detection. This flexibility reduces development time and costs, making automation accessible to small and medium-sized enterprises.

Another cornerstone of this technology is sensor integration. Force-torque sensors, LiDAR, and machine vision cameras provide robots with real-time environmental awareness. In automotive assembly lines, robots equipped with 3D vision can identify and align car parts within millimeter-level tolerances, even if components are slightly misplaced. Similarly, force sensors enable delicate operations like inserting microchips into circuit boards without damaging fragile materials. These capabilities blur the line between automated and human-driven precision.

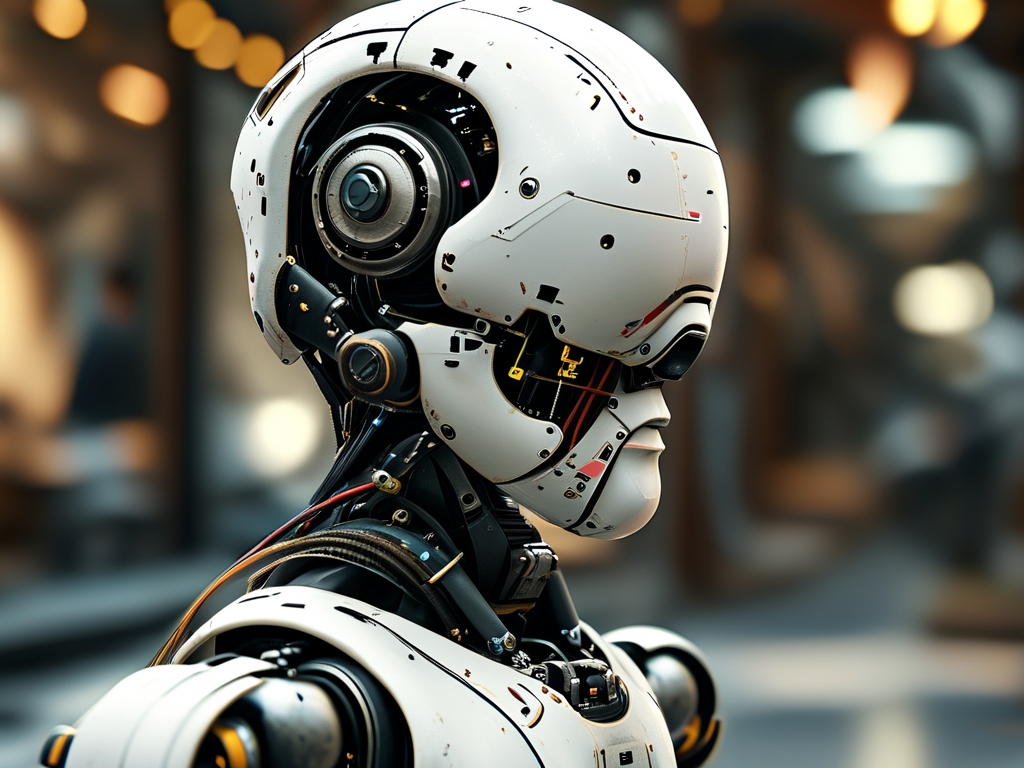

Software plays an equally vital role. Motion planning algorithms ensure that robotic arms move efficiently between tasks, avoiding collisions and minimizing idle time. Machine learning models further enhance adaptability by enabling robots to learn from past errors or optimize workflows based on data patterns. For instance, collaborative robots (cobots) in electronics manufacturing can adjust their grip strength after analyzing feedback from failed pick-and-place attempts, improving success rates over time.

However, implementing robotics assembly technology isn’t without challenges. System calibration demands meticulous attention to detail, as even minor misalignments can lead to operational failures. Engineers must also address interoperability issues when integrating robots with existing machinery or IoT-enabled production lines. Cybersecurity is another growing concern, as networked robots become potential targets for malicious attacks that could disrupt entire assembly processes.

The applications of this technology extend beyond traditional factories. In healthcare, surgical robots assemble microscopic instruments during procedures, enhancing precision in operations like neurosurgery. Agricultural robots use similar principles to automate crop harvesting and sorting, while logistics companies deploy assembly-line robots to manage warehouse inventory. As the technology matures, its adoption in unconventional sectors—such as construction and space exploration—continues to expand.

Looking ahead, advancements in artificial intelligence and edge computing are set to redefine robotics assembly. AI-driven predictive maintenance could reduce downtime by anticipating mechanical wear, while 5G connectivity enables real-time data exchange between distributed robotic systems. Meanwhile, the rise of digital twins—virtual replicas of physical robots—allows engineers to simulate and optimize assembly processes before deploying them in the real world.

In , robotics assembly technology represents a fusion of innovation and practicality, driving efficiency across global industries. By understanding its components—from modular hardware to intelligent software—businesses can harness its potential to streamline operations, reduce costs, and push the boundaries of what automation can achieve. As this field evolves, staying informed about emerging trends will be key to maintaining a competitive edge in an increasingly automated landscape.