The evolution of robotic assembly technology has revolutionized manufacturing, enabling precision, efficiency, and scalability in production lines. At its core, this technology integrates mechanical engineering, software algorithms, and sensor-based feedback systems to automate complex assembly tasks. Understanding its principles requires dissecting three foundational elements: hardware design, control systems, and adaptive learning mechanisms.

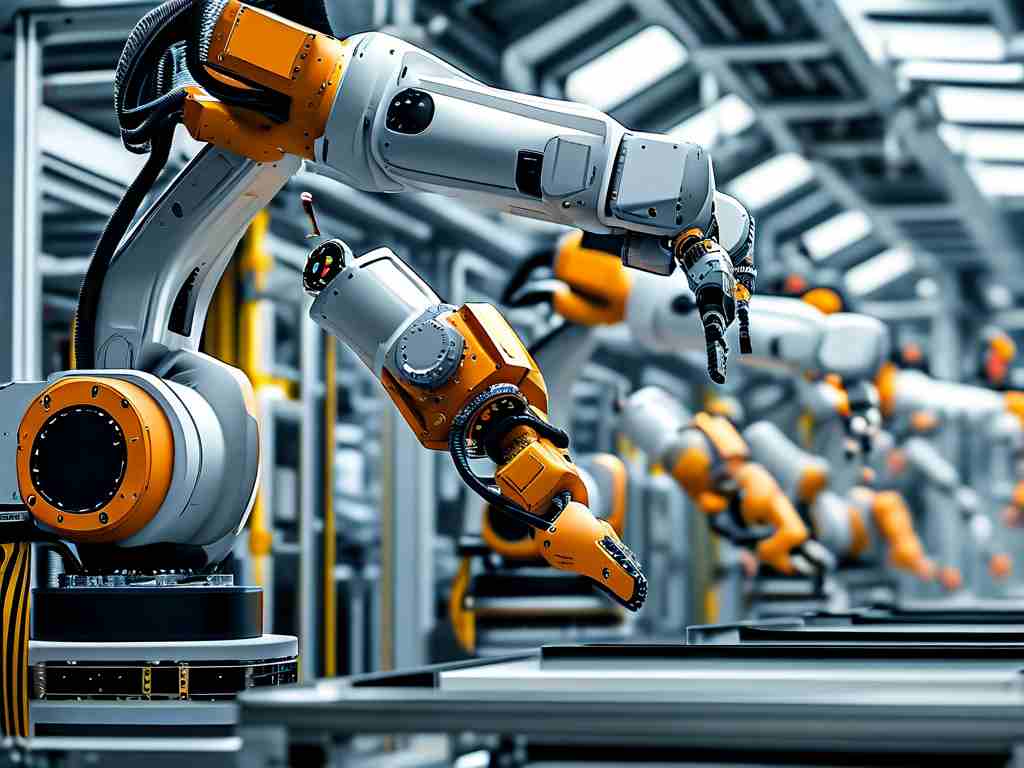

Hardware Design and Mechanical Integration

Modern robotic assembly systems rely on modular hardware architectures. Industrial robots, such as articulated or Cartesian models, are equipped with end-effectors tailored for specific tasks—grippers for part handling, screwdrivers for fastening, or vision-guided tools for alignment. These components are engineered for durability and repeatability, ensuring consistent performance under high-speed operations. For example, collaborative robots (cobots) incorporate lightweight materials and torque sensors to safely interact with human operators, a feature critical in hybrid assembly environments.

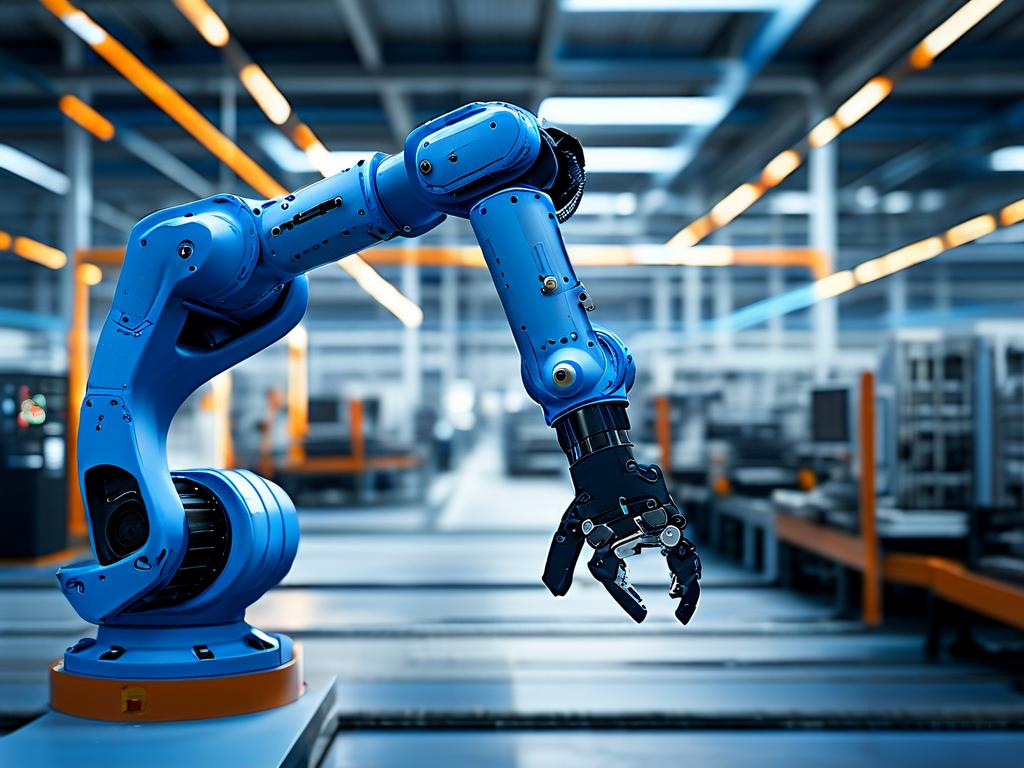

Control Systems and Real-Time Decision Making

The "brain" of robotic assembly lies in its control software. Programmable Logic Controllers (PLCs) and motion controllers synchronize robotic movements with conveyor belts, part feeders, and quality inspection stations. Advanced systems employ machine vision to identify component orientations or detect defects. A case in point is the use of 3D cameras paired with convolutional neural networks (CNNs) to adjust gripper paths dynamically, compensating for variances in part placement. Real-time data processing ensures sub-millimeter accuracy, even when assembling microelectronics or aerospace components.

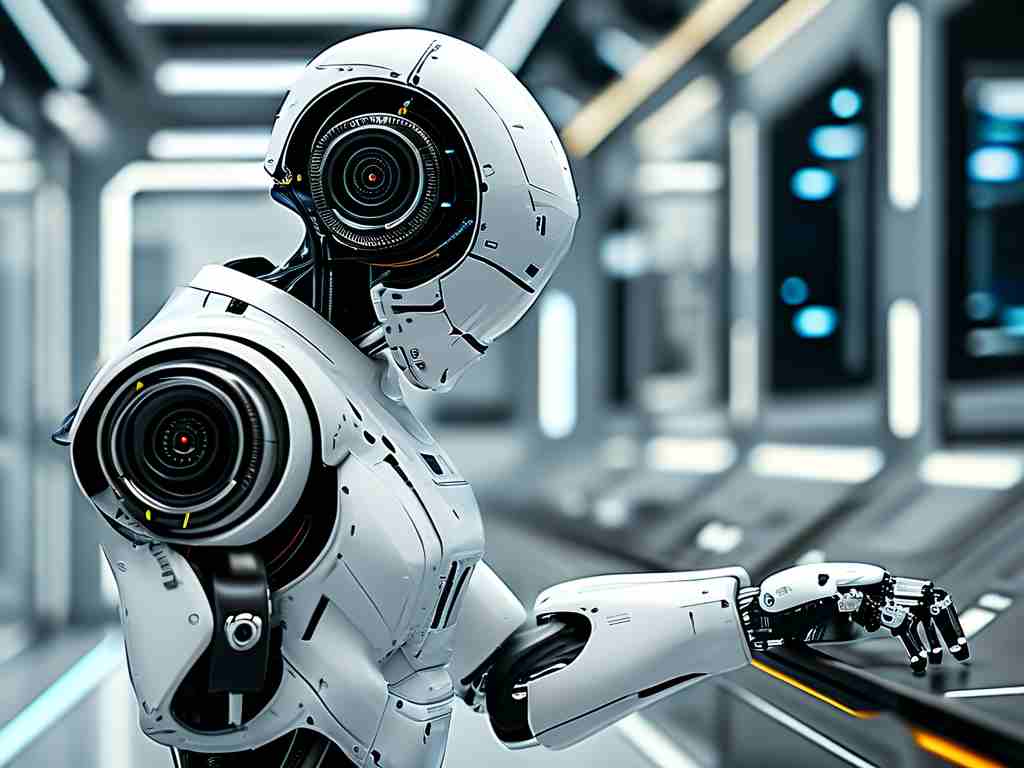

Adaptive Learning and AI-Driven Optimization

Unlike traditional automation, next-gen robotic assembly leverages artificial intelligence to self-optimize. Reinforcement learning algorithms enable robots to refine motion trajectories based on historical performance data. For instance, a robot might reduce cycle times by 15% after analyzing thousands of iterations of a welding sequence. Additionally, digital twin technology simulates assembly workflows before deployment, identifying bottlenecks or collision risks. This proactive approach minimizes downtime and enhances system resilience.

Challenges and Future Directions

Despite advancements, challenges persist. High initial costs and integration complexity deter small-scale manufacturers. Moreover, assembling deformable materials (e.g., cables or rubber) remains problematic due to unpredictable physics. Researchers are addressing these gaps through innovations like soft robotics and tactile sensors that mimic human dexterity. Another frontier is swarm robotics, where multiple robots collaborate on large-scale assemblies—a concept tested in automotive battery module production.

In , robotic assembly technology is a synergy of precision engineering and intelligent computation. As industries push toward Industry 4.0, advancements in AI, material science, and human-robot collaboration will further redefine manufacturing paradigms. Companies adopting these systems today position themselves at the forefront of productivity and innovation.