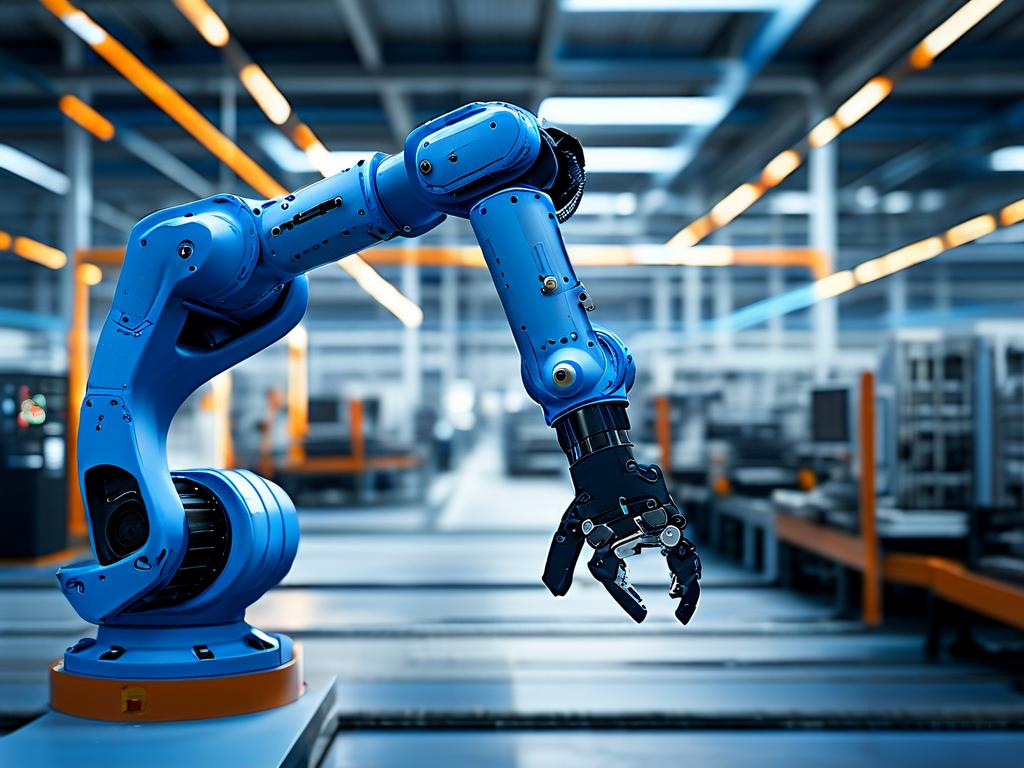

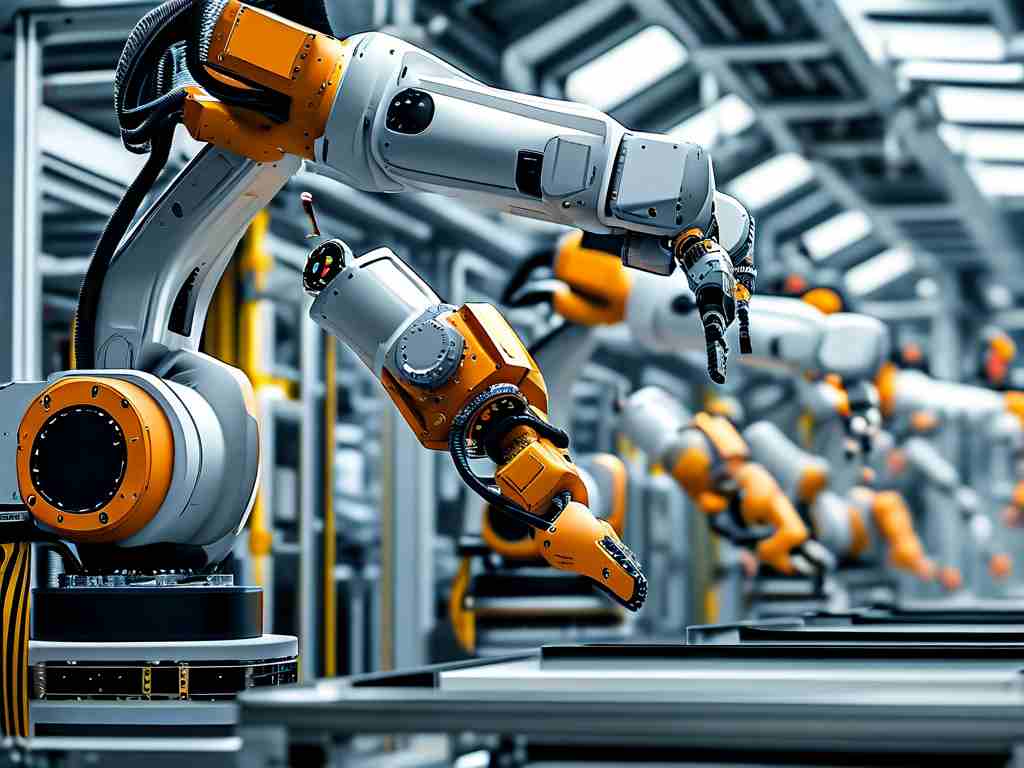

Industrial robot technology stands at the forefront of modern manufacturing, driving unprecedented efficiency and innovation across global industries. This transformative field merges advanced mechanics with artificial intelligence to create systems that perform tasks with remarkable precision and speed. Historically, industrial robots emerged in the mid-20th century, primarily in automotive assembly lines, but today they permeate diverse sectors like electronics, healthcare, and logistics. Key advancements include the integration of sophisticated sensors and machine learning algorithms, enabling robots to adapt to dynamic environments. For instance, vision systems allow machines to detect defects in real-time, reducing errors by up to 90% in quality control processes. Such capabilities stem from ongoing research in areas like collaborative robotics, where robots work alongside humans without safety cages, enhancing workplace flexibility.

The benefits of industrial robot technology are manifold, boosting productivity while lowering operational costs. In automotive plants, robotic arms assemble vehicles at speeds unattainable by human workers, cutting production times by half. Similarly, in electronics manufacturing, miniature robots handle delicate components with micron-level accuracy, minimizing waste and improving yield rates. Beyond efficiency, these systems enhance worker safety by taking over hazardous duties such as welding or handling toxic materials. Statistics show that factories adopting robotics report a 50% reduction in workplace injuries. However, challenges persist, including high initial investments and the need for specialized maintenance. Concerns about job displacement also arise, though many experts argue that robotics creates new roles in programming and supervision, fostering a skilled workforce evolution.

Looking ahead, emerging trends promise even greater revolutions. The rise of AI-driven autonomous robots will enable self-optimizing systems that learn from data, predicting failures before they occur. Innovations in soft robotics and IoT connectivity will expand applications into sectors like agriculture, where drones and automated harvesters address labor shortages. Despite hurdles like cybersecurity risks and ethical debates, the future shines bright as governments and corporations invest heavily in this tech. Ultimately, industrial robot technology not only reshapes industries but also propels humanity toward a smarter, more sustainable era, where machines and humans collaborate for shared progress.