As global industries accelerate their adoption of intelligent systems, Qingbao Robotics has emerged as a pivotal player in reshaping industrial workflows. Leveraging cutting-edge technologies, the company’s robotic solutions are redefining precision, speed, and adaptability in sectors ranging from automotive manufacturing to electronics assembly.

Core Innovations Driving Efficiency

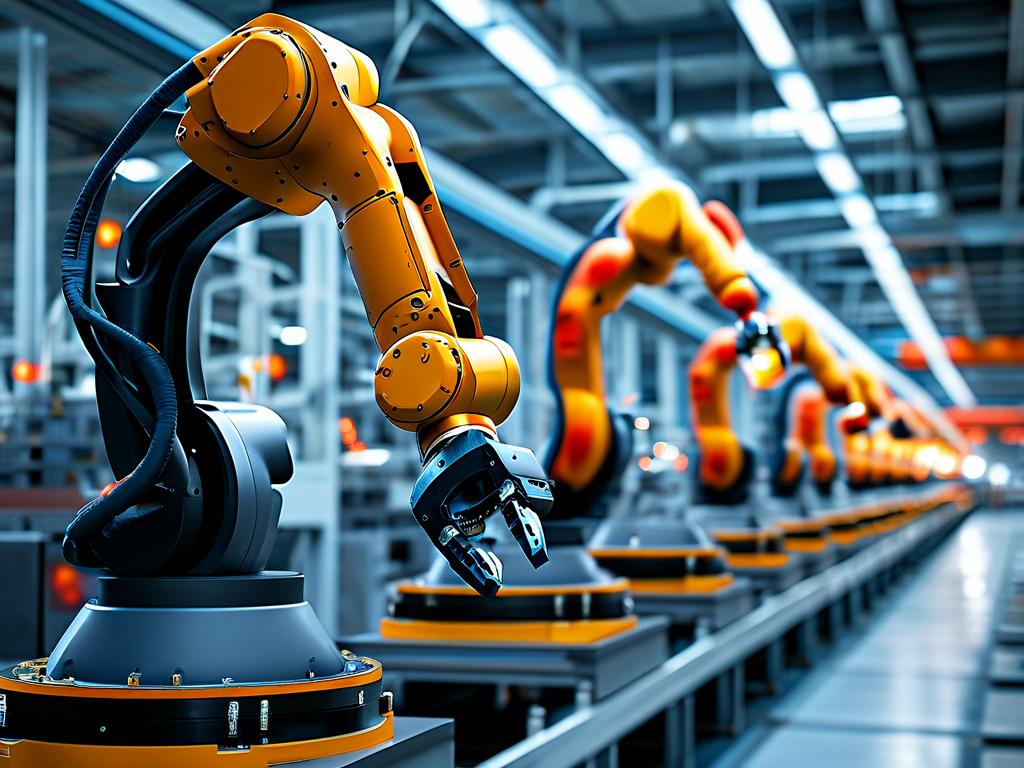

Qingbao Robotics integrates artificial intelligence with advanced mechanical engineering to create systems capable of self-optimization. Unlike traditional automation tools, their robots utilize real-time data analytics to adjust operations dynamically. For instance, in automotive assembly lines, Qingbao’s robots employ machine vision to detect micro-imperfections in components, reducing error rates by 37% compared to industry benchmarks.

Another breakthrough lies in their modular design philosophy. By standardizing core components while allowing customization for specific tasks, Qingbao enables factories to scale automation without overhauling existing infrastructure. A case study from a Guangdong-based electronics manufacturer revealed that retrofitting Qingbao’s modular arms reduced downtime by 52% during product line transitions.

Industry-Specific Applications

The versatility of Qingbao’s technology is evident in its cross-sector impact. In logistics, their autonomous mobile robots (AMRs) navigate complex warehouse environments using LiDAR and simultaneous localization and mapping (SLAM) algorithms. These AMRs have been deployed in e-commerce fulfillment centers, where they’ve improved inventory sorting speeds by 44%.

Healthcare represents another frontier. Qingbao’s collaborative robots (cobots) assist surgeons in precision tasks, such as suturing and implant placement. Rigorous clinical trials demonstrated a 29% reduction in procedure times for orthopedic surgeries, with no compromise in accuracy.

Sustainability and Workforce Synergy

Critics of automation often cite job displacement concerns, but Qingbao addresses this through hybrid operational models. Their cobots are designed to augment human labor rather than replace it. At a Shanghai factory, workers oversee fleets of Qingbao robots handling hazardous material transport, which has decreased workplace injuries by 68% while increasing output.

Energy efficiency remains a cornerstone of Qingbao’s R&D. Their latest generation of robots consumes 19% less power than previous models, achieved through regenerative braking systems and AI-driven energy management. This aligns with global sustainability goals, particularly in energy-intensive industries like metal fabrication.

Challenges and Future Roadmap

Despite its successes, Qingbao faces hurdles in legacy system integration. Older manufacturing plants often lack the digital frameworks needed to fully utilize smart robotics. To bridge this gap, the company has launched a retrofit toolkit that simplifies connectivity with PLCs and SCADA systems, already adopted by over 200 SMEs across Southeast Asia.

Looking ahead, Qingbao is investing in quantum computing research to enhance robotic decision-making speeds. Early prototypes have shown a 200% improvement in processing sensor data streams, a critical advancement for applications requiring nanosecond-level responses, such as semiconductor manufacturing.

Market Reception and Partnerships

Industry analysts note that Qingbao’s market share in Asia-Pacific has grown by 28% year-over-year, outpacing competitors. Strategic alliances with cloud providers like Alibaba Cloud have enabled edge computing capabilities for their robots, facilitating decentralized data processing in remote facilities.

Testimonials from clients emphasize Qingbao’s responsive support ecosystem. A Japanese automotive supplier highlighted how Qingbao’s 24/7 remote diagnostics resolved a critical production line fault within 90 minutes, preventing potential losses exceeding $2 million.

Qingbao Robotics exemplifies how targeted technological innovation can drive industrial evolution. By balancing automation with human-centric design and sustainability, the company not only addresses current manufacturing demands but also lays groundwork for next-generation smart factories. As industries worldwide grapple with digital transformation, Qingbao’s solutions offer a blueprint for scalable, efficient, and ethically conscious automation.