Situated at the heart of China's manufacturing renaissance, Foshan has emerged as a critical hub for industrial robotics development. Local manufacturers combine precision engineering with adaptive automation solutions, positioning the city as a driving force in smart manufacturing across Asia. This article explores how Foshan-based robotics firms are reshaping production paradigms through technological innovation and strategic partnerships.

The competitive edge of Foshan's robotics industry stems from its vertically integrated supply chains. Enterprises like TechBotics and MechInnovate maintain in-house R&D departments working on proprietary motion control algorithms while collaborating with regional universities on material science breakthroughs. This dual approach enables rapid prototyping cycles – some manufacturers have reduced development timelines by 40% compared to international counterparts through modular design architectures.

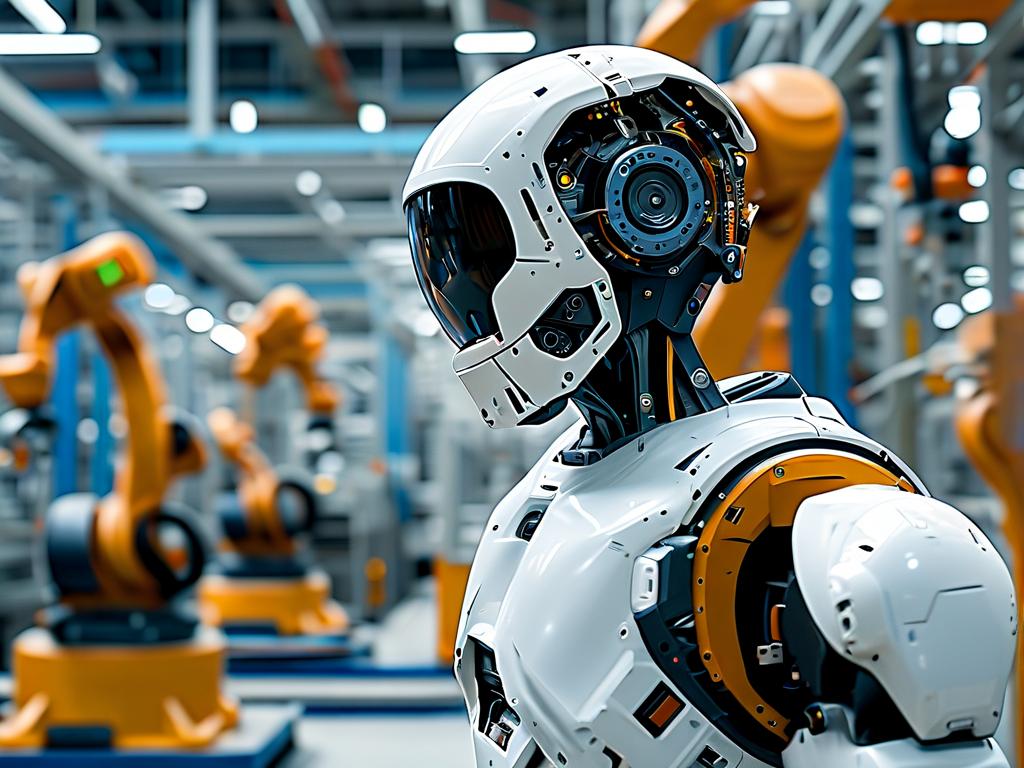

A distinctive characteristic of Foshan's automation ecosystem lies in its focus on human-machine collaboration. Unlike conventional robotic systems requiring safety cages, next-generation cobots produced in the region incorporate advanced force-limiting sensors and machine vision. The FS-900 series collaborative arm, for instance, achieves positional accuracy of ±0.02mm while maintaining compliance thresholds below 150N, making it ideal for delicate assembly tasks in electronics manufacturing.

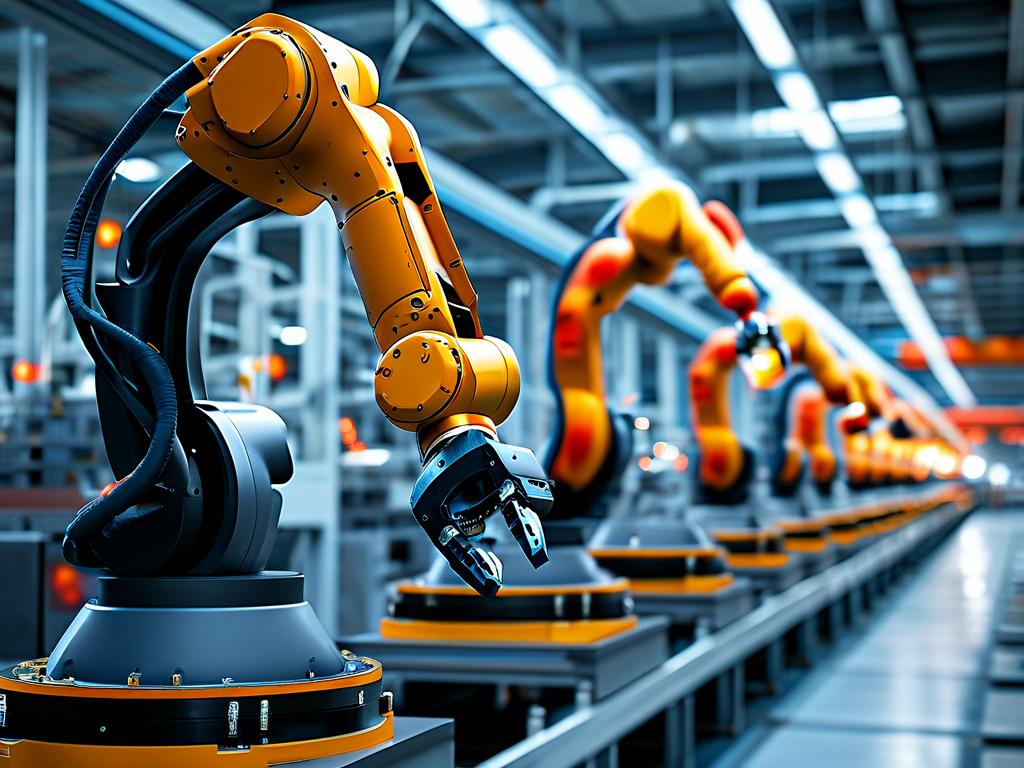

Energy efficiency represents another frontier for local innovators. The latest generation of delta robots from Foshan plants demonstrates 22% lower power consumption through regenerative braking systems and optimized servo motor configurations. These advancements align with China's carbon neutrality goals while providing cost savings for high-volume production facilities.

Customization capabilities distinguish Foshan manufacturers in global markets. Rather than offering standardized solutions, companies employ configurable kinematic chains that adapt to specific industrial workflows. A notable case involves the automotive sector, where robotic welding cells can be reconfigured within 72 hours to accommodate new vehicle chassis designs – a flexibility benchmark surpassing European competitors.

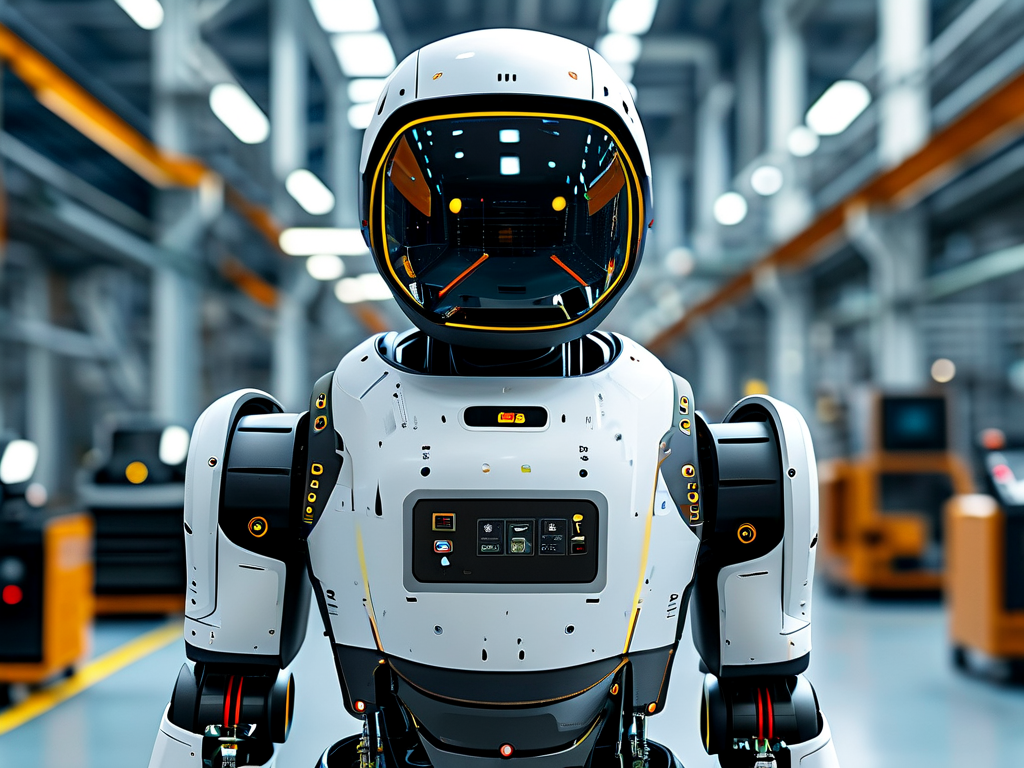

The integration of industrial IoT platforms with robotic systems marks Foshan's progression towards Industry 4.0 standards. Proprietary operating systems like RoS-Connect enable real-time performance monitoring across multiple production lines, with predictive maintenance algorithms reducing downtime by up to 35%. This digital transformation extends to remote troubleshooting capabilities, allowing engineers in Germany or Mexico to diagnose and resolve equipment issues through secure cloud channels.

Material innovation plays a crucial role in enhancing robotic durability. Partnerships with metallurgy institutes have yielded specialized aluminum alloys that reduce manipulator weight by 18% without compromising structural integrity. Such advancements prove particularly valuable in high-speed packaging applications where reduced inertia translates to faster cycle times.

Workforce development initiatives ensure sustained technological leadership. The Foshan Robotics Academy collaborates with manufacturers to deliver certified training programs, producing over 2,000 automation specialists annually. This talent pipeline supports the city's ambition to capture 15% of the global industrial robotics market by 2028.

As global manufacturers seek resilient supply chains, Foshan's robotics firms are expanding international partnerships. Recent joint ventures with Southeast Asian automotive suppliers demonstrate the export potential of modular automation solutions tailored for emerging markets. With continued investment in AI-driven vision systems and quantum computing applications for path optimization, Foshan's industrial robotics sector stands poised to redefine smart manufacturing in the coming decade.