The construction industry is witnessing a paradigm shift with the emergence of robotic wall demolition systems. These machines combine hydraulic force, precision sensors, and advanced algorithms to redefine how structures are dismantled. Unlike traditional manual methods involving sledgehammers or explosive charges, robotic demolition offers unprecedented control while addressing critical challenges like worker safety and environmental impact.

Mechanics of Robotic Demolition

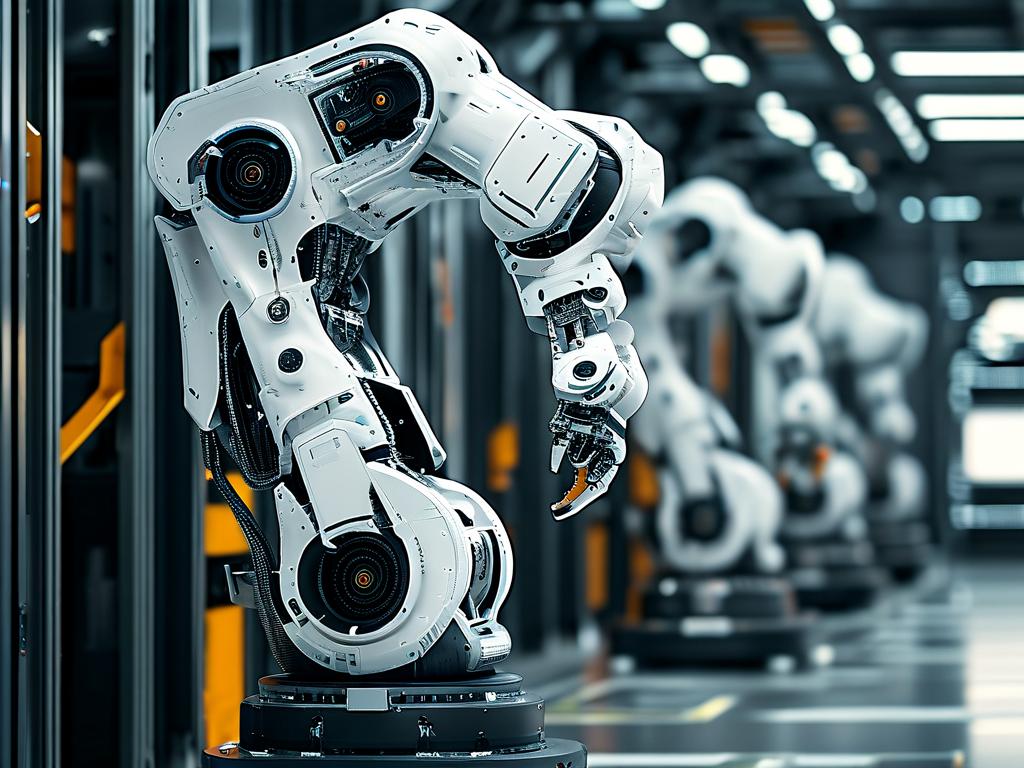

Modern demolition robots employ modular designs with interchangeable attachments – crushers, drills, and hydraulic hammers – that adapt to materials ranging from brittle drywall to reinforced concrete. The Brokk 400, for instance, utilizes a patented shock-absorption system that redirects impact vibrations away from critical components, enabling continuous operation at 3,200 blows per minute. Embedded LiDAR scanners create real-time 3D maps of workspaces, allowing operators to program exclusion zones within ±2cm accuracy, particularly valuable in historic renovations where adjacent structures require protection.

A breakthrough lies in the force feedback systems. When encountering rebar clusters, sensors automatically adjust torque distribution across multiple contact points, preventing equipment jamming. This contrasts sharply with conventional methods where unexpected metal obstructions frequently cause project delays.

Operational Advantages

-

Safety Enhancement: Remote operation capabilities allow workers to control machines from 150-meter distances, drastically reducing injury risks from falling debris. The DustGuard 2.0 filtration system integrated in Husqvarna models captures 98.7% of particulate matter below 10μm, maintaining airborne pollutant levels under 15 μg/m³ – well below OSHA’s 50 μg/m³ threshold.

-

Economic Efficiency: While initial investments range from $85,000 to $300,000, these robots demonstrate ROI within 14-18 months through reduced labor costs. A case study in Chicago showed a 40% cost reduction in demolishing 12,000 sq.ft of masonry walls compared to crew-based approaches.

-

Precision Engineering: Computer-vision systems enable surgical material removal. During the Munich Urban Renewal Project, robots successfully extracted 1940s-era asbestos insulation from brick walls with 0.03% material loss, preserving 92% of original structural elements for reuse.

Technical Limitations and Solutions

Current models face challenges in ultra-high-strength concrete (UHSC) exceeding 150 MPa. However, prototype plasma arc attachments developed by KIBER GmbH show promise, achieving localized thermal stresses of 1,800°C to fracture UHSC matrices without collateral damage. Battery limitations persist, though new solid-state power packs extend operational durations to 9 hours – a 210% improvement over 2020 models.

Environmental Impact Metrics

Robotic demolition reduces carbon footprints through material sorting algorithms. The ECOROBOT-X12 system automatically separates concrete, metal, and wood into distinct streams, achieving 87% recycling rates versus 45% in manual processes. Noise pollution is curtailed to 68 dB(A) at 10 meters – quieter than standard concrete mixers.

Future Developments

The integration of BIM (Building Information Modeling) with demolition robots is underway. Early trials in Singapore demonstrate machines autonomously cross-referencing architectural schematics to identify load-bearing walls with 99.2% accuracy. Swarm robotics represents another frontier – synchronized fleets of 20-kg micro-demolishers recently completed a complex structural takedown in Tokyo 40% faster than traditional single-unit operations.

Regulatory frameworks are adapting to this technology. The EU’s forthcoming Machinery Directive 2025 mandates dual AI validation systems for demolition path planning, requiring redundant neural networks to confirm structural stability calculations before each operation.

As these systems evolve, they’re expanding into niche applications. Underwater demolition bots with pressurized hydraulic systems now assist in dam modifications, while compact 15-kg units help firefighters create emergency passages through collapsed buildings. The convergence of robotics and demolition expertise is creating a $4.7 billion market projected to grow at 11.8% CAGR through 2030, fundamentally transforming how we interact with built environments.