The realm of modern robotics manufacturing has evolved dramatically, driven by cutting-edge technologies that redefine how robots are conceptualized, built, and deployed. This transformation isn't just about assembling metal parts; it's a symphony of artificial intelligence, precision engineering, and sustainable practices reshaping industries from automotive to healthcare. As we delve into this intricate process, it becomes clear that today's robots are not mere machines but intelligent entities crafted through meticulous steps.

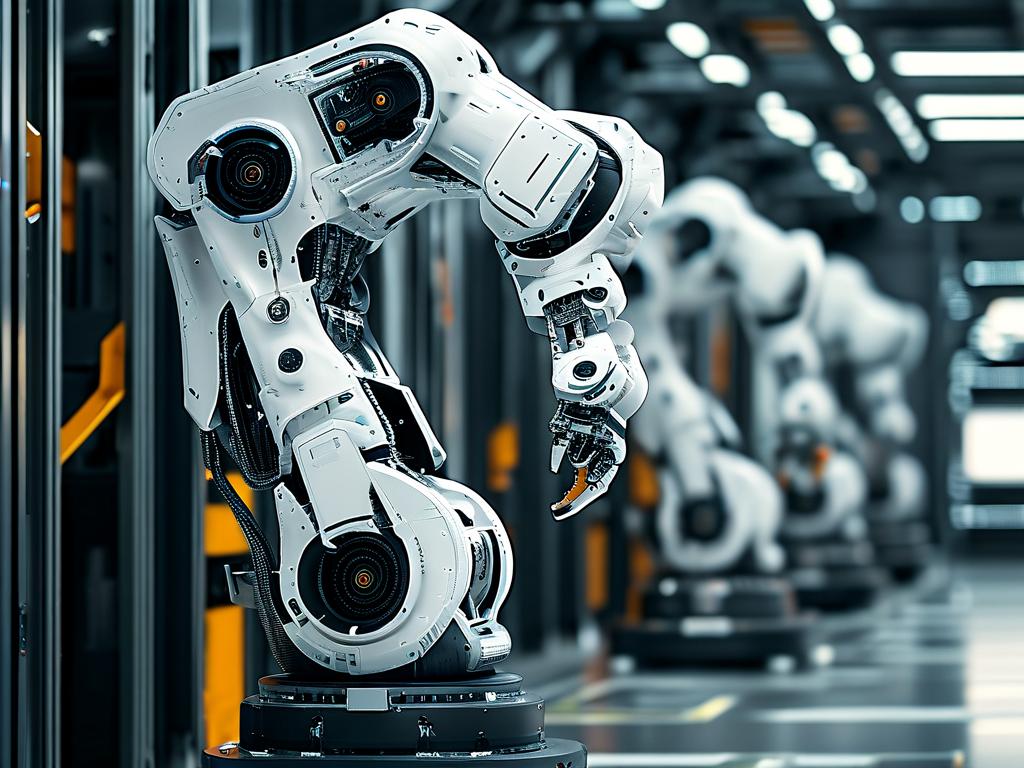

First, the design phase leverages advanced software tools like CAD (Computer-Aided Design) and simulation platforms. Engineers start by modeling virtual prototypes, optimizing for factors such as weight, durability, and energy efficiency. For instance, a robotic arm intended for factory assembly might undergo hundreds of digital iterations before physical creation begins. This virtual testing minimizes real-world errors and accelerates innovation. Here's a simple Python snippet demonstrating how a basic joint movement could be simulated:

import numpy as np

def calculate_joint_angle(desired_position):

# Simplified calculation for robotic joint

current_angle = 0

angle_adjustment = np.arctan2(desired_position[1], desired_position[0])

return angle_adjustment

# Example usage: target = [3, 4] for position in 2D space

print(calculate_joint_angle([3, 4]))

Moving to material selection, modern techniques prioritize lightweight composites like carbon fiber and smart alloys that respond to environmental stimuli. These materials reduce operational costs and enhance longevity, especially in harsh settings like deep-sea exploration or space missions. Coupled with this, additive manufacturing—3D printing—revolutionizes production by enabling complex geometries that were once impossible. A single print run can create intricate components with embedded sensors, slashing waste and lead times compared to traditional machining.

Programming is where intelligence breathes life into robots. Using machine learning algorithms, developers train systems to adapt autonomously. Consider a service robot in a hospital: it learns navigation paths through reinforcement learning, avoiding obstacles while delivering supplies. This isn't static coding but dynamic evolution, where neural networks process real-time data from cameras and LiDAR. Such advancements stem from open-source frameworks like ROS (Robot Operating System), fostering collaboration across global teams.

Testing and integration form the final hurdle, involving rigorous trials in simulated and real environments. Robots undergo stress tests for reliability, with AI-driven diagnostics predicting failures before they occur. This phase ensures seamless deployment, whether in smart factories automating production lines or in homes assisting with daily tasks. Challenges persist, such as ethical concerns over job displacement and cybersecurity risks, but ongoing research aims to balance innovation with societal benefits.

Looking ahead, the fusion of IoT and edge computing promises even smarter robots that communicate in real-time networks. Sustainable manufacturing will gain traction, using recycled materials and energy-efficient processes to combat climate change. As this field advances, it empowers humanity to tackle global issues, from disaster response to personalized medicine. In essence, modern robotics manufacturing isn't just about building machines; it's about crafting a future where technology elevates human potential, making our world safer, more efficient, and infinitely more connected.