Robot wall drilling technology represents a cutting-edge advancement in construction and demolition, where automated systems precisely bore through walls without human intervention. This innovation leverages sophisticated principles to enhance safety, accuracy, and efficiency in various industries, from building renovations to infrastructure development. At its core, the technology relies on a combination of sensory inputs, intelligent control systems, and mechanical execution to achieve flawless results.

The fundamental principle begins with environmental perception. Robots are equipped with advanced sensors like lidar or ultrasonic detectors that scan the wall surface in real-time. These sensors create detailed 3D maps, identifying obstacles such as pipes, wires, or structural reinforcements hidden within the wall. By analyzing this data, the system calculates optimal drilling points to avoid hazards, ensuring minimal damage and maximum precision. For instance, lidar sensors emit laser pulses to measure distances and surface irregularities, while cameras provide visual feedback for fine-tuning positions. This sensory integration mimics human vision but with superior consistency, reducing errors that often plague manual operations.

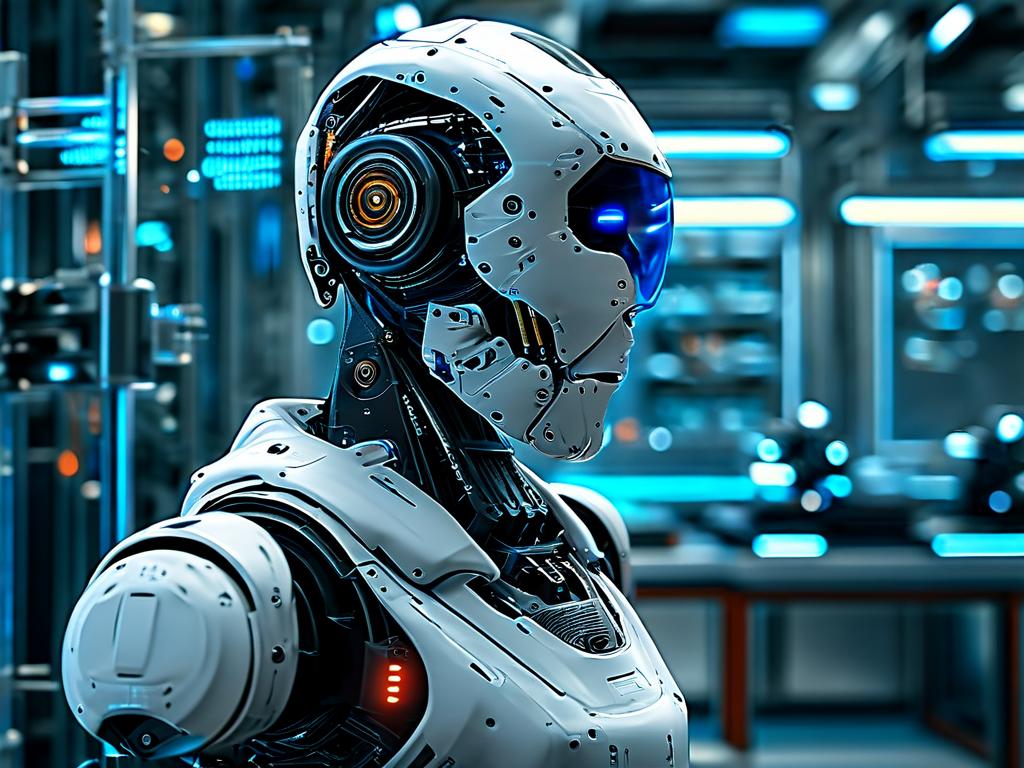

Next, the control system acts as the brain of the operation. It processes sensor data using algorithms based on artificial intelligence or machine learning. These algorithms interpret the wall's composition—whether it's concrete, brick, or drywall—and adjust drilling parameters like speed, pressure, and depth accordingly. The system continuously monitors feedback during drilling, making micro-adjustments to maintain stability. If unexpected resistance is detected, it can pause or alter the approach dynamically. This adaptive control not only prevents equipment damage but also conserves energy by optimizing power usage. Such intelligence stems from years of research in robotics, where predictive models learn from past tasks to improve future performance, creating a self-correcting loop that evolves with each job.

Mechanical execution forms the final pillar of the technology. A robotic arm, often articulated with multiple joints for flexibility, maneuvers the drill bit with high precision. The arm is driven by servo motors that provide smooth, controlled movements, while the drill itself incorporates features like variable torque settings and automatic bit changes. During operation, the robot applies consistent force, avoiding human fatigue-related inconsistencies. This mechanical synergy ensures clean, uniform holes for applications like installing utilities or creating access points. Moreover, safety protocols are embedded throughout; for example, emergency stop functions activate if sensors detect nearby movement, protecting workers in shared environments.

Applications of this technology span diverse fields. In construction, robots handle repetitive drilling tasks in hazardous areas like high-rise buildings or confined spaces, boosting productivity by up to 50% compared to manual labor. Demolition projects benefit from controlled precision, reducing debris and minimizing structural risks. Even in disaster response, these robots can swiftly create openings for rescue operations without endangering human teams. However, challenges persist, such as high initial costs and the need for specialized maintenance, which limit widespread adoption. Future advancements may integrate more AI for predictive analytics or use collaborative robots that work alongside humans, making the technology more accessible and versatile.

In essence, robot wall drilling technology embodies a transformative shift towards automation, driven by principles that prioritize safety, efficiency, and adaptability. As industries embrace smarter solutions, this innovation promises to reshape how we interact with built environments, paving the way for safer, more sustainable practices in the years ahead.