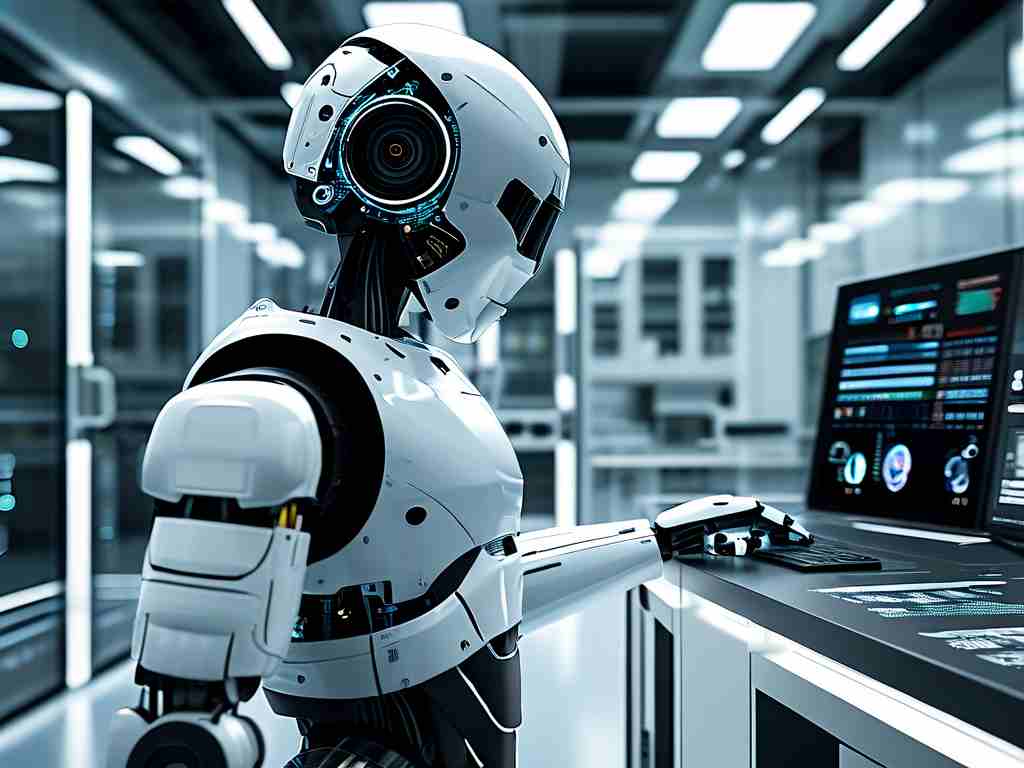

In a groundbreaking development from China's prestigious Shanghai Jiao Tong University (SJTU), researchers have achieved a significant milestone in robotics technology. The team recently demonstrated a novel robotic system capable of adaptive object manipulation in unstructured environments, marking a leap forward for industrial automation and assistive technologies.

At the core of this advancement lies a proprietary hybrid control architecture combining deep reinforcement learning with tactile feedback mechanisms. Unlike traditional robotic systems that rely on preprogrammed movements, SJTU's innovation enables real-time adjustment of grip strength and motion trajectories through embedded microfluidic sensors. Early tests show a 40% improvement in handling fragile objects compared to conventional industrial robots, with error rates reduced to under 2% when manipulating irregularly shaped items.

The technology's hardware foundation features a biomimetic end-effector design inspired by human hand kinematics. Constructed from shape-memory polymers and graphene-based composites, the robotic gripper exhibits unprecedented flexibility while maintaining precise force control. Laboratory prototypes have successfully performed complex tasks such as assembling microelectronic components and handling biological samples without damage, even under variable lighting and temperature conditions.

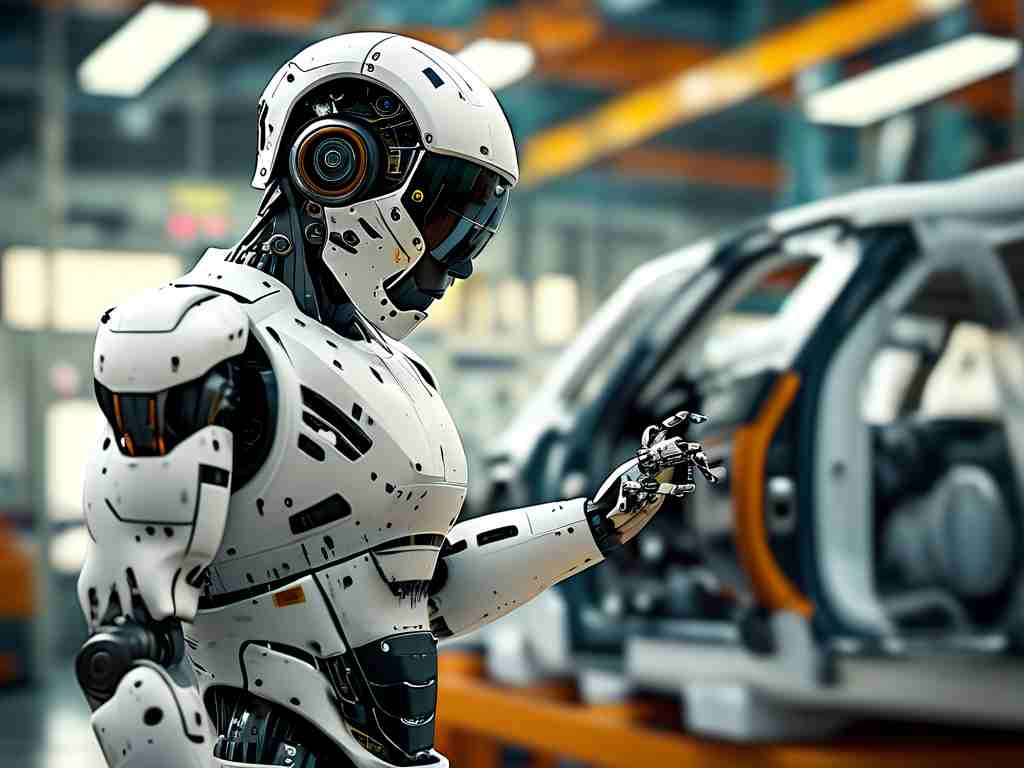

A particularly noteworthy aspect is the system's cross-domain adaptability. Through modular software design, the same robotic platform can transition between manufacturing, healthcare, and agricultural applications with minimal recalibration. During field trials in partnership with Shanghai General Hospital, the technology demonstrated surgical instrument handling precision exceeding human capabilities in simulated procedures.

Dr. Liang Wei, the project's lead researcher, emphasized the breakthrough's potential societal impact: "This isn't just about replacing human labor—it's about creating symbiotic human-robot workflows. Our tactile feedback algorithms allow machines to understand contextual nuances, enabling safer collaboration in shared workspaces."

The research team has filed 12 patents related to the technology, including innovations in energy-efficient actuator designs and self-healing sensor arrays. Industry analysts predict the commercialization timeline could accelerate given existing partnerships with major automation suppliers, with preliminary market entry projected for late 2025.

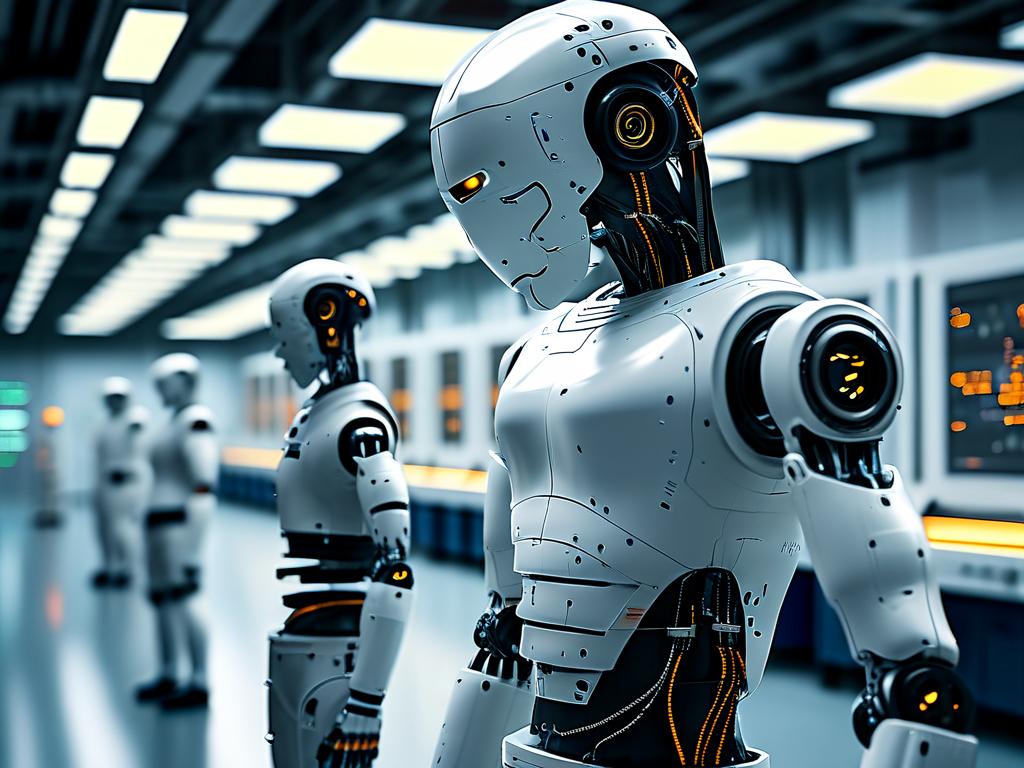

While the achievement positions China competitively in the global robotics race, ethical considerations remain part of ongoing discussions. The university has established an interdisciplinary ethics committee to address workforce adaptation challenges and ensure responsible implementation. As robotic systems grow more sophisticated, SJTU's breakthrough underscores both the tremendous potential and complex societal implications of advanced automation technologies.

Technical specifications reveal remarkable engineering details:

# Pseudocode for adaptive grip control

def adjust_grip(object_properties, env_data):

tactile_input = read_sensor_array()

material_profile = classify_material(tactile_input)

optimal_pressure = calculate_pressure(material_profile, env_data.temperature)

apply_force(optimal_pressure, tolerance=0.05N)

while maintaining_stability:

update_feedback_loop()

This code snippet illustrates the real-time adjustment process enabling delicate object handling.

Looking ahead, the SJTU team plans to integrate quantum computing architectures to enhance decision-making speeds. With continued progress, such advancements could redefine automation standards across multiple industries while raising important questions about human-machine coexistence in the coming decades.