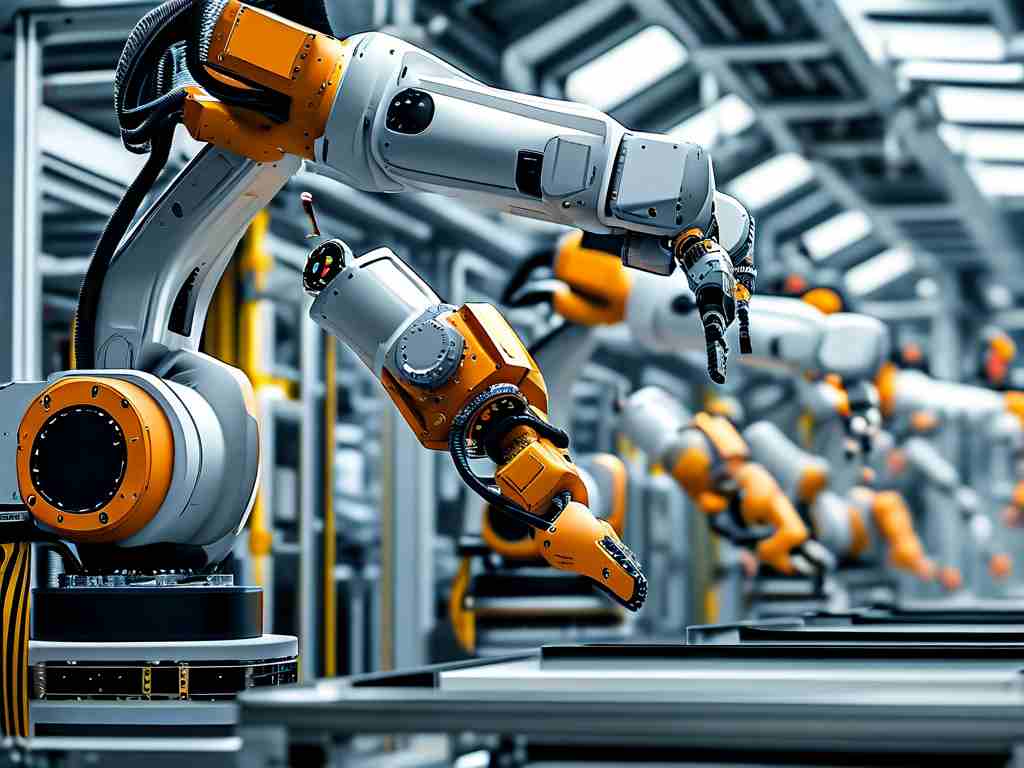

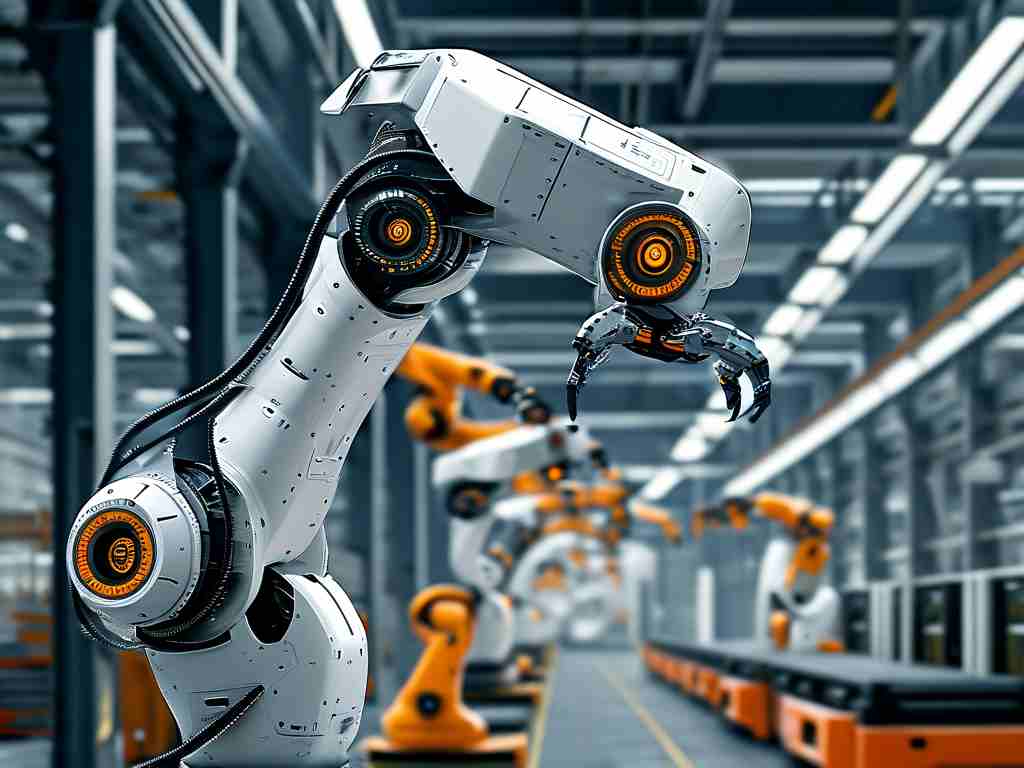

The rapid evolution of robotic systems continues to redefine industries worldwide. Recent advancements in sensor integration and machine learning algorithms have enabled robots to perform tasks with unprecedented precision. This article explores three groundbreaking developments shaping the future of automation.

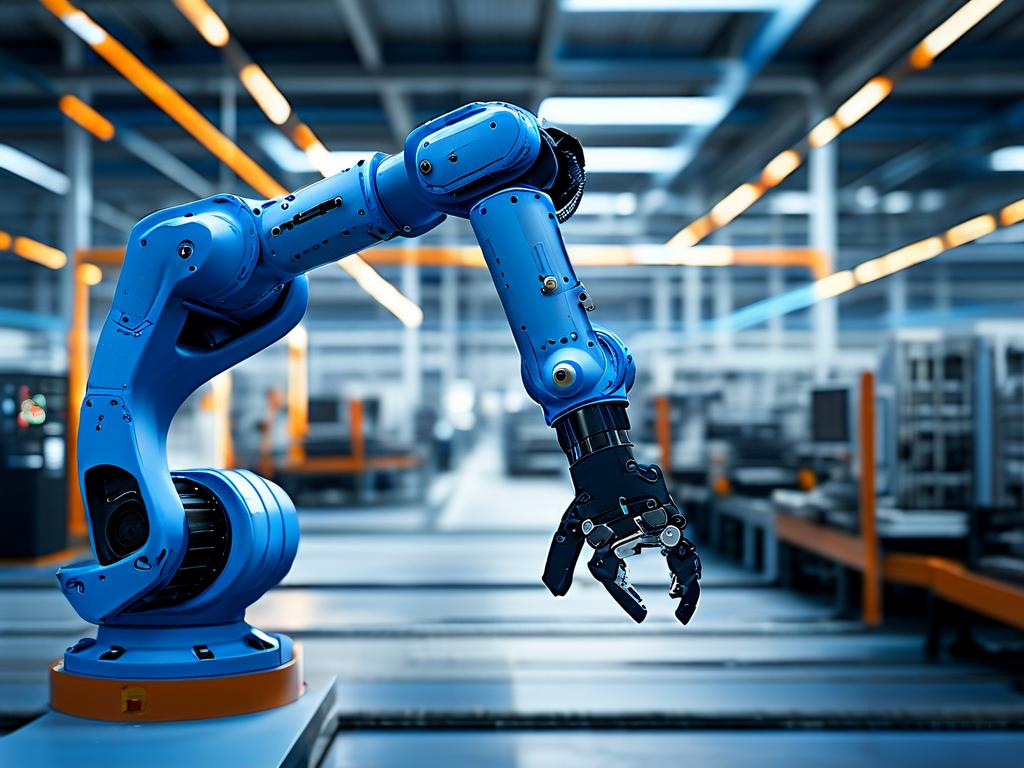

One significant breakthrough lies in adaptive grasping mechanisms. Traditional robotic arms relied on pre-programmed movements, but next-gen systems now utilize real-time tactile feedback. Engineers at Boston Dynamics recently demonstrated a prototype capable of manipulating irregularly shaped objects—from delicate glassware to deformable packaging materials—with human-like dexterity. This innovation stems from combining force-torque sensors with convolutional neural networks trained on 15 million simulated grip scenarios.

The healthcare sector has witnessed transformative applications through surgical assistance robots. The da Vinci Xi System, now deployed in over 2,000 hospitals globally, exemplifies this trend. Unlike earlier models limited to steady-hand functions, newer iterations incorporate augmented reality overlays. Surgeons can view 3D anatomical reconstructions during operations, while haptic feedback systems provide resistance simulations matching actual tissue responses. Clinical trials at Johns Hopkins Hospital revealed a 37% reduction in procedure times for complex neurosurgeries when using these enhanced systems.

Agricultural automation has reached new heights through autonomous crop management drones. Startups like FarmWise deploy fleets of solar-powered robots that identify weeds with 99.3% accuracy using multispectral imaging. What sets these apart is their decision-making architecture: instead of relying solely on cloud-based processing, edge computing modules analyze field data locally. This reduces latency to 0.8 seconds—critical when navigating through crops at 12 km/h. California almond farmers reported 22% higher yields during pilot tests last growing season.

Underpinning these advancements is the maturation of neuromorphic computing chips. IBM's TrueNorth processor, mimicking biological neural networks, consumes 0.1% of the energy required by conventional GPUs for pattern recognition tasks. When integrated with Boston University's SLAM (Simultaneous Localization and Mapping) algorithms, these chips enable robots to navigate dynamic environments without external positioning systems. Warehouse robots equipped with this technology reduced collision incidents by 89% in Amazon's latest fulfillment centers.

Despite these leaps, technical hurdles persist. Energy density limitations constrain mobile robot operational durations, though MIT's solid-state battery prototype (demonstrating 500Wh/kg) shows promise. Ethical considerations also emerge as automation displaces certain job categories—a 2024 World Economic Forum report predicts 23 million manufacturing roles will transition to robotics maintenance positions by 2030.

The fusion of quantum computing with robotic systems looms as the next frontier. Early experiments at CERN leverage qubit processors to optimize particle accelerator maintenance robot paths, achieving 94% faster route calculations than classical computers. As these technologies mature, we approach an era where robots not only replicate human actions but develop problem-solving strategies through quantum-enhanced reinforcement learning.

From assembly lines to operating theaters, robotic innovations demonstrate that we're not merely automating tasks—we're reengineering the boundaries of intelligent machinery. These developments underscore a crucial reality: the robotics revolution isn't coming; it's already here, reshaping our world one algorithm at a time.