The evolution of robotic grinding technology has revolutionized precision manufacturing across industries. By integrating advanced automation with material processing techniques, this innovation addresses critical challenges in surface finishing, deburring, and component shaping. Unlike traditional manual methods, robotic systems deliver consistent quality while operating in hazardous environments – from foundries handling molten metal castings to aerospace facilities processing turbine blades.

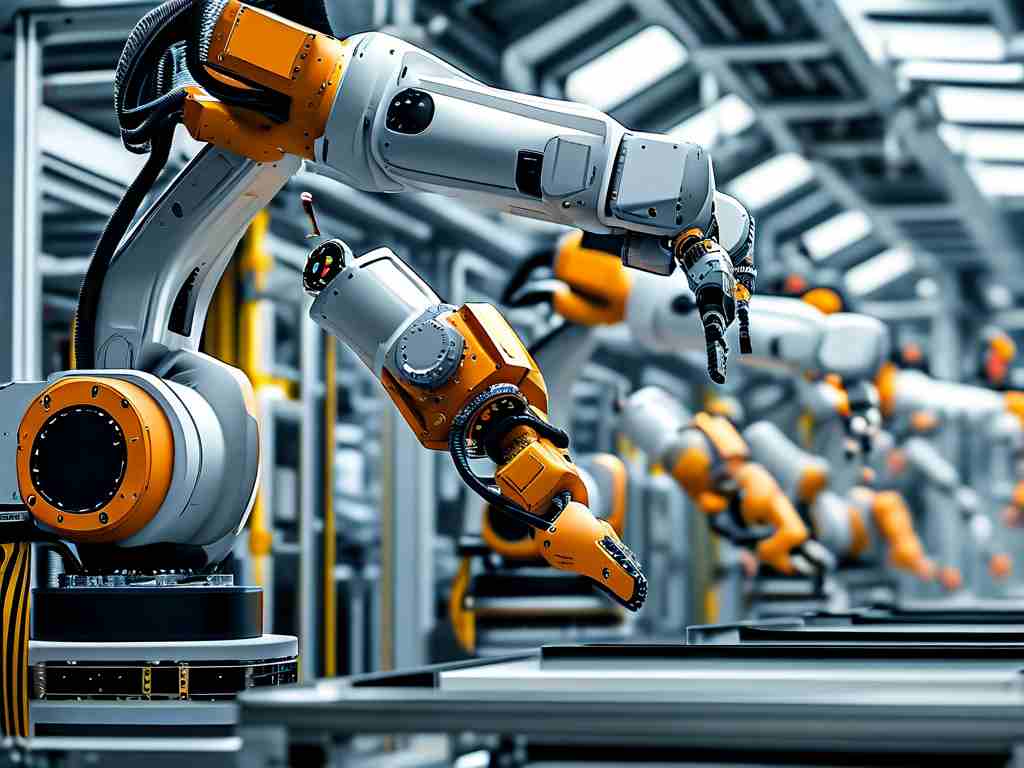

At its core, robotic grinding relies on three interconnected components: adaptive force control systems, real-time path correction algorithms, and multi-axis mechanical articulation. Modern robots employ torque sensors that detect resistance variations as low as 0.5N·m, enabling automatic adjustments to grinding pressure. This proves vital when working with composite materials like carbon fiber-reinforced polymers, where excessive force risks delamination.

The emergence of machine vision has further enhanced capabilities. Vision-guided robots using 3D laser scanners can map irregular surfaces with 20μm accuracy, automatically generating tool paths without CAD models. For instance, automotive manufacturers now use this technology to finish die-cast aluminum engine blocks, achieving surface roughness (Ra) values below 1.6μm – a 40% improvement over manual polishing.

Energy efficiency represents another breakthrough. Variable-frequency drives in modern grinding robots reduce power consumption by 35% compared to conventional systems. When combined with predictive maintenance algorithms analyzing motor current signatures, these systems achieve 95% operational uptime. The automotive sector reports 18-month ROI periods after adopting such solutions for brake drum finishing lines.

However, implementation challenges persist. Material variability remains a critical hurdle – a single batch of stainless steel can exhibit 15% hardness fluctuations. Leading manufacturers like ABB and KUKA have developed hybrid control systems that combine neural networks with physical models. These systems automatically compensate for material inconsistencies by cross-referencing historical process data with real-time spectral analysis of grinding sparks.

The medical device industry demonstrates unique applications. Surgical instrument manufacturers employ micro-grinding robots with 0.01mm precision spindles to finish arthroscopic tools. These sterile-environment systems utilize ceramic grinding wheels and oil-free vacuum extraction, achieving mirror finishes while eliminating cross-contamination risks observed in manual processes.

Looking ahead, the integration of digital twins promises transformative potential. Engineers now simulate entire grinding processes virtually, predicting outcomes with 92% accuracy before physical implementation. This approach recently helped an aerospace supplier reduce titanium alloy part rejection rates from 8% to 0.7% during wing spar production.

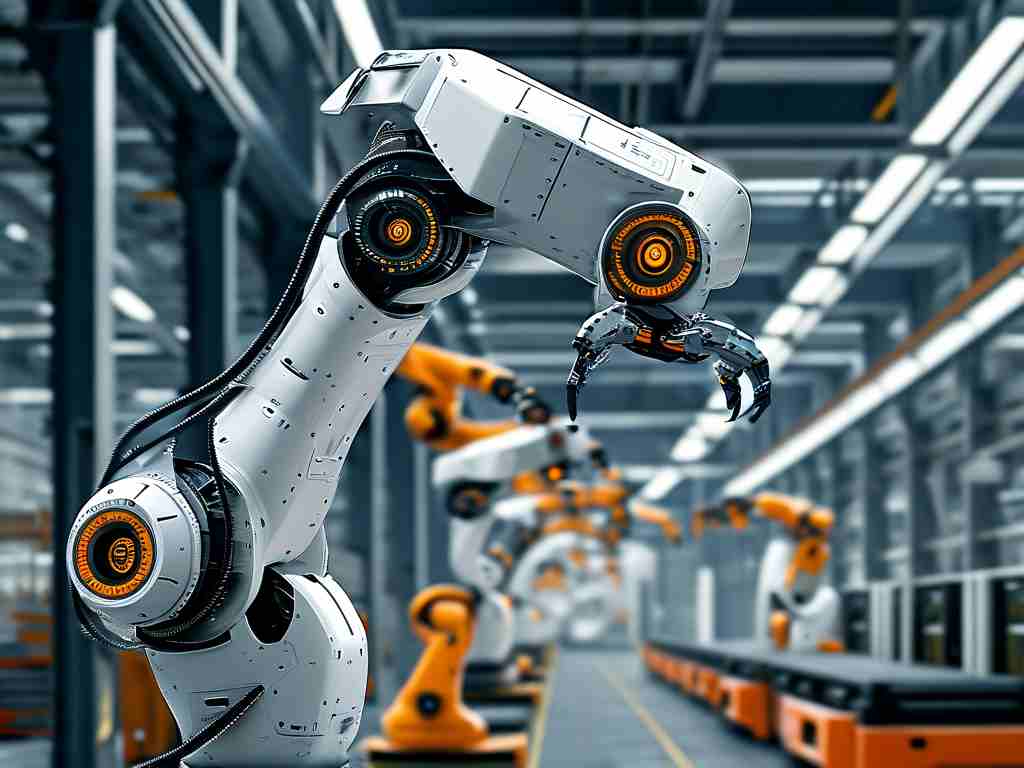

While robotic grinding technology continues advancing, human expertise remains crucial. Skilled technicians program complex contouring sequences and oversee quality assurance – particularly for custom components like hydroelectric turbine runners. The optimal solution blends robotic efficiency with human judgment, creating symbiotic systems that outperform either approach in isolation.

As Industry 4.0 accelerates adoption, robotic grinding stands poised to redefine manufacturing standards. From reducing workplace injuries to enabling new material applications, this technology exemplifies how automation can enhance both productivity and product quality across industrial sectors. Future developments in haptic feedback and quantum computing may further push the boundaries of what's achievable in precision material processing.