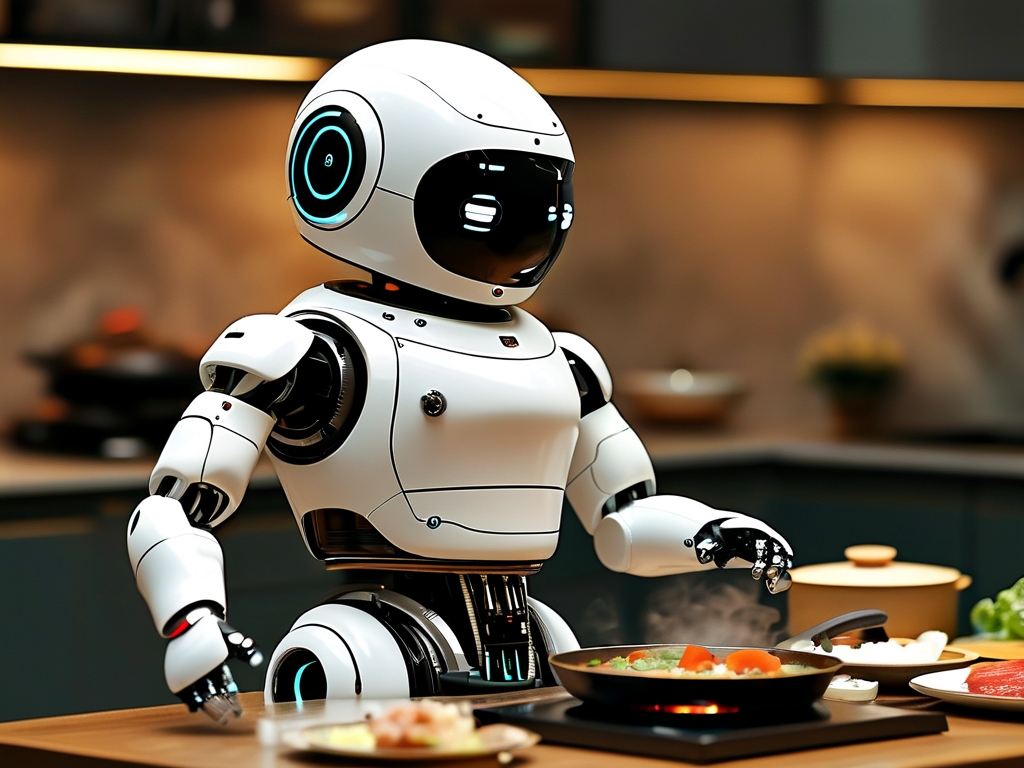

The integration of robotics into culinary practices has revolutionized how meals are prepared, offering a blend of precision engineering and culinary artistry. At its core, robotic cooking technology relies on three fundamental pillars: sensory input processing, algorithmic decision-making, and mechanical execution. This article explores the intricate workflow behind automated cooking systems and their growing impact on modern kitchens.

Sensory Foundations

Modern cooking robots employ multispectral sensors to replicate – and often surpass – human sensory capabilities. Infrared thermometers measure surface temperatures of ingredients with ±0.5°C accuracy, while hyperspectral cameras analyze food composition through wavelength patterns. A prototype developed by MIT's Food Computing Lab demonstrated how such systems can detect potato starch content variations invisible to the human eye, automatically adjusting cooking parameters for optimal crispiness.

Tactile feedback systems represent another breakthrough. The University of Tokyo's "ChefBot" utilizes piezoelectric arrays in its grippers to assess ingredient textures. When handling delicate proteins like salmon, the pressure sensitivity adjusts in real-time to prevent structural damage – a task even skilled chefs find challenging during repetitive tasks.

The Brain Behind the Brawn

At the heart of every cooking robot lies its processing unit, where machine learning models transform raw data into culinary actions. Unlike static programming, these systems employ reinforcement learning algorithms that evolve through continuous feedback. Moley Robotics' flagship model, for instance, improved its pancake-flipping success rate from 72% to 98% over six months by analyzing 12,000 failed attempts.

Natural language processing (NLP) has become crucial for user interaction. When a user commands "make the sauce richer," the system cross-references this instruction with its flavor database containing over 200,000 chemical compound profiles. This semantic analysis enables adjustments in ingredient ratios rather than simple parameter tweaking.

Precision in Motion

The mechanical execution phase showcases remarkable engineering feats. Delta-type robotic arms, favored for their speed and precision, can achieve 0.02mm positional accuracy – essential for tasks like sushi rice placement. Thermal management systems present unique challenges; KUKA's culinary division solved heat distortion in frying arms using liquid-cooled actuators that maintain ±1°C stability during eight-hour operations.

Dexterous end-effectors (tools) demonstrate specialized innovation. Hellmann Engineering's adaptive whisk attachment alters its wire density based on batter viscosity readings, achieving 30% better aeration than manual whisking. For stir-frying, magnetic induction woks paired with titanium spatulas enable 10°C/s temperature changes while withstanding 500,000 stir cycles without wear.

Integration Challenges

Despite technological leaps, obstacles persist in kitchen integration. The "variable resistance problem" – where ingredients like thawing meat alter physical properties during cooking – requires adaptive torque control. Siemens' Foodomat series addresses this through real-time mass spectrometry, adjusting stirrer motor output every 50 milliseconds.

Energy efficiency remains another frontier. Commercial models like Rotenko's RK-9X reduced power consumption by 40% using regenerative braking systems that capture kinetic energy from chopping motions, storing it in supercapacitors for thermal components.

Ethical and Practical Considerations

As these technologies enter home kitchens, new debates emerge. Culinary traditionalists argue that robot-cooked meals lack "soul," while advocates highlight consistency benefits for chain restaurants. Interestingly, a 2023 Stanford study found 68% of participants couldn't distinguish between human- and robot-made dishes in blind tastings, though emotional attachment to the food decreased by 22%.

Looking ahead, the convergence of robotics with molecular gastronomy promises unprecedented culinary possibilities. Experimental models like ETH Zurich's "NanoChef" can assemble dishes at the micron level, creating textures impossible through manual preparation. As costs decrease from current $200,000+ commercial systems to projected $5,000 home models by 2028, robotic cooking may transition from industrial novelty to household staple – redefining our relationship with food preparation in the digital age.