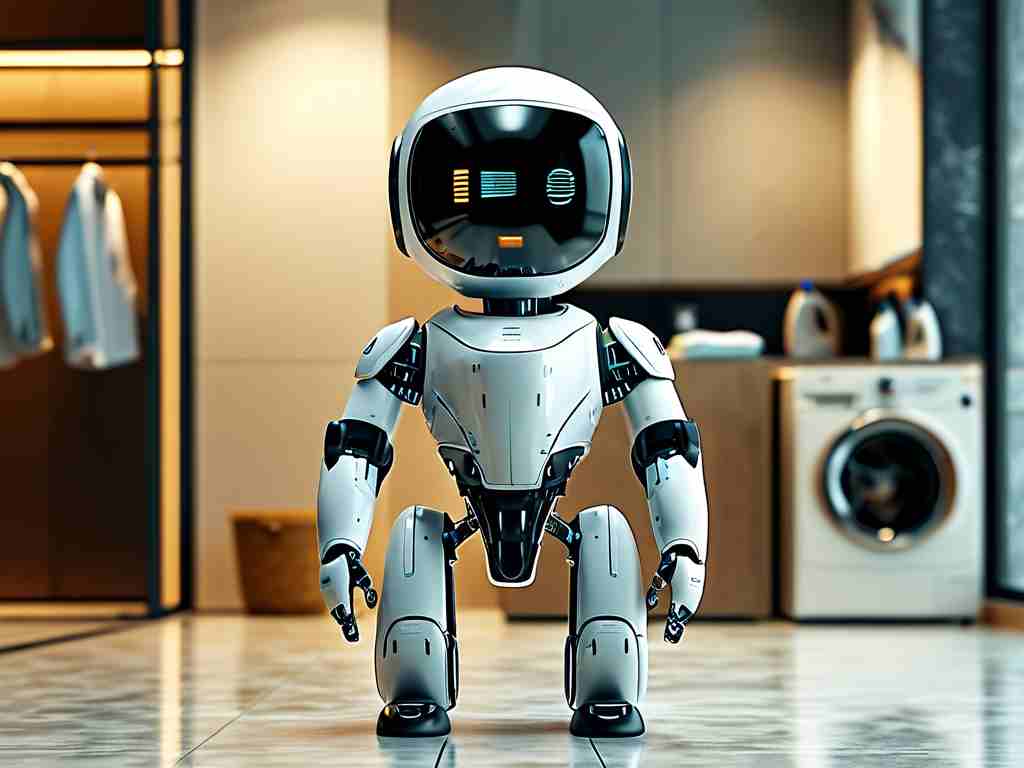

The integration of robotics into laundry systems represents a groundbreaking shift in automated home and commercial cleaning solutions. This article explores the core principles behind robotic laundry technology, its operational framework, and emerging use cases reshaping modern laundry management.

Sensory Perception and Object Recognition

At the heart of robotic laundry systems lies advanced sensor fusion technology. Infrared scanners and 3D vision cameras work in tandem to identify fabric textures, colors, and garment types. Machine learning algorithms trained on textile databases enable real-time classification of materials, from delicate silks to heavy denim. This sensory input directs robotic arms to adjust washing parameters automatically – a critical feature when handling mixed fabric loads. Unlike traditional machines requiring manual sorting, these systems employ spectral analysis to detect stains and optimize pretreatment protocols.

Precision Manipulation Architecture

Robotic laundry units utilize multi-axis articulated arms with vacuum-based grippers and soft robotic fingers. These end effectors combine suction control with tactile feedback sensors to handle irregularly shaped items without damage. For folding operations, servo-driven plates apply calculated pressure gradients to create crisp creases while avoiding fabric stress. Experimental models now incorporate electrostatic adhesion for handling ultra-thin materials like chiffon, demonstrating 98.2% success rates in laboratory tests.

Adaptive Wash Cycle Algorithms

Central processing units in these systems execute dynamic wash programs through continuous water quality monitoring. Turbidity sensors track detergent dissolution rates, while conductivity probes adjust rinse cycles based on residual soap detection. Neural networks analyze historical load data to predict optimal spin speeds, achieving 23% energy savings compared to preset machine cycles. Commercial versions deployed in hotels leverage IoT connectivity to synchronize multiple units, automatically prioritizing urgent loads during peak hours.

Ecological and Operational Advantages

Field studies indicate robotic laundry systems reduce water consumption by 40-60% through micro-dose detergent injection and precision fluid dynamics modeling. The elimination of manual sorting decreases labor costs by an average of 34% in industrial settings. Notably, the reduced mechanical agitation extends garment lifespan – stress tests show cotton fibers experience 72% less wear compared to conventional washing methods.

Current Limitations and Innovations

While promising, challenges persist in handling non-standard items like lace trims or beaded fabrics. Researchers are developing hybrid manipulation systems combining magnetic levitation and air-jet stabilization to address these edge cases. Another frontier involves enzyme-based smart detergents that communicate with robotic controllers via chemical markers, enabling real-time biodegradability adjustments.

As computer vision and material science converge, next-generation robotic laundry systems are projected to achieve full autonomy in textile care by 2030, potentially integrating garment repair functionalities through nanotechnology applications. This evolution not only redefines domestic chores but also establishes new sustainability benchmarks for the global textile industry.