The integration of robotic unpacking technology into industrial workflows marks a pivotal shift in modern manufacturing and logistics. As global supply chains grow increasingly complex, businesses are turning to automated solutions to enhance efficiency, reduce labor costs, and minimize errors. This article explores the mechanics of robotic unpacking systems, their applications across industries, and the challenges they aim to address in today’s fast-paced operational environments.

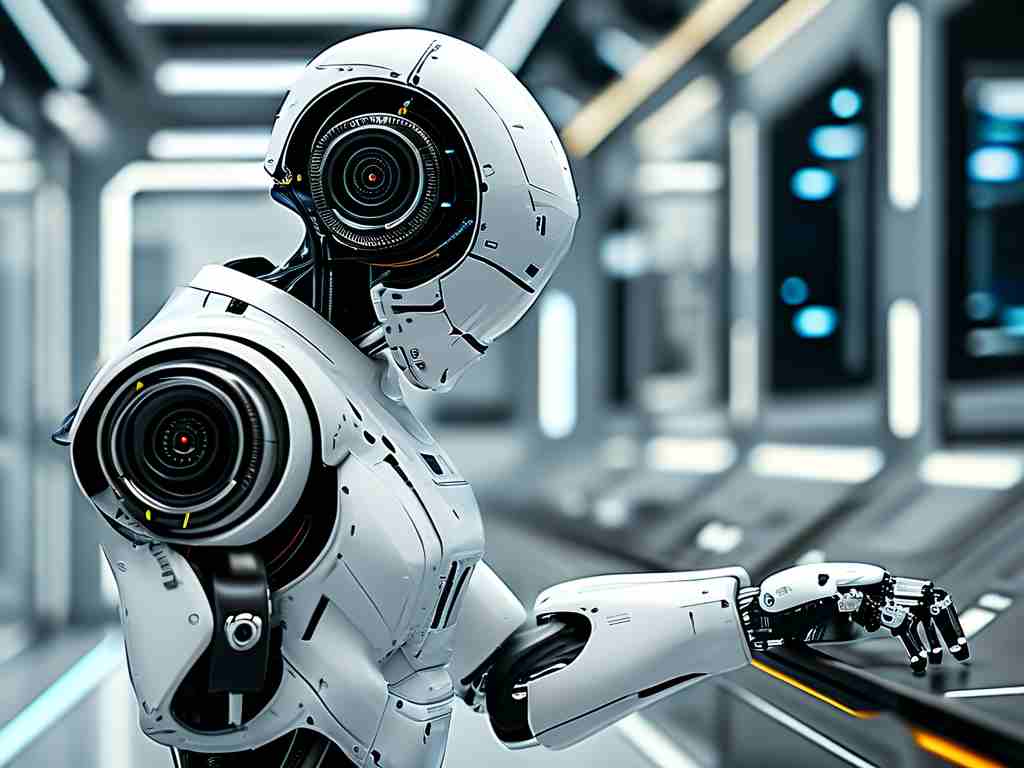

At its core, robotic unpacking technology leverages advanced vision systems, machine learning algorithms, and precision actuators to identify, handle, and process packaged items. Unlike traditional manual methods, these systems utilize 3D cameras and sensors to scan parcels in real time, determining optimal gripping points while avoiding damage to contents. For instance, a robotic arm equipped with force feedback sensors can delicately unwrap fragile electronics or adjust its grip for irregularly shaped objects—capabilities that significantly reduce material waste.

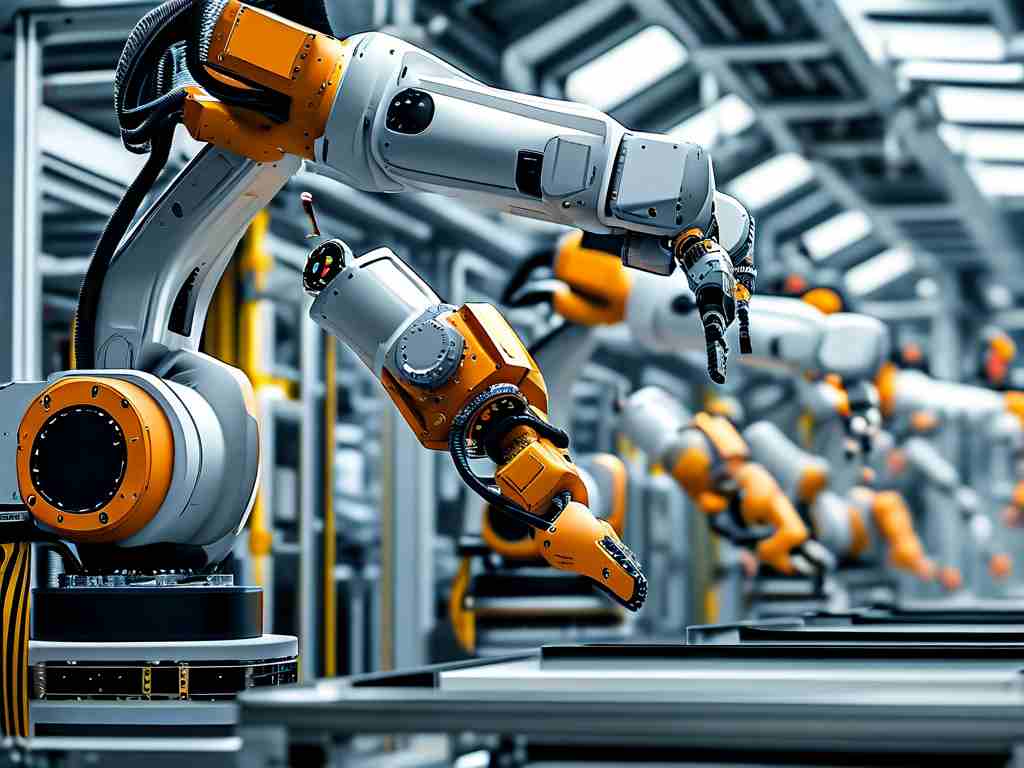

In logistics hubs, this technology streamlines high-volume operations. A major e-commerce company recently reported a 40% reduction in unpacking time after deploying robotic systems in their distribution centers. The robots autonomously sort incoming shipments, remove protective layers, and route items to designated processing zones. This not only accelerates order fulfillment but also minimizes human exposure to repetitive strain injuries—a critical advantage in workplaces prioritizing employee safety.

The manufacturing sector similarly benefits from robotic unpacking solutions. Automotive plants, for example, use these systems to unload components from standardized containers with submillimeter accuracy. By integrating with enterprise resource planning (ERP) software, robots can verify part numbers against production schedules, flagging discrepancies before assembly lines face delays. Such synchronization between physical unpacking and digital data systems exemplifies Industry 4.0 principles in action.

Despite its advantages, implementing robotic unpacking technology presents challenges. Initial setup costs remain substantial, particularly for small and medium enterprises. Customizing robots to handle diverse packaging materials—from rigid plastic clamshells to biodegradable wraps—requires ongoing software updates and hardware modifications. Additionally, maintaining peak performance in dynamic environments demands continuous calibration. A food processing facility in Germany encountered this firsthand when their system initially struggled with frost-covered frozen food packages until engineers refined the thermal imaging protocols.

Looking ahead, innovations in artificial intelligence promise to expand robotic unpacking capabilities. Reinforcement learning models now enable robots to "practice" unpacking tasks in virtual simulations, reducing real-world trial periods by up to 70%. Collaborative robots (cobots) designed to work alongside humans are also gaining traction, combining automated efficiency with human problem-solving for complex unpacking scenarios.

Ethical considerations accompany these advancements. While automation boosts productivity, workforce reskilling initiatives become imperative to mitigate job displacement concerns. Forward-thinking companies are addressing this by creating hybrid roles where employees oversee robotic systems while developing technical troubleshooting skills—a model observed in Scandinavian warehousing firms.

In , robotic unpacking technology represents more than mere mechanical innovation; it embodies the convergence of engineering precision and intelligent automation. As industries worldwide embrace these systems, the focus must remain on balancing operational gains with sustainable workforce strategies. The unpacking robots of today are not just tools—they are catalysts for redefining how industries approach efficiency, safety, and scalability in an increasingly automated future.