Robotics experiment technology has transformed numerous industries by enabling precise testing and real-world implementation of robotic systems. This advancement stems from rigorous experimental processes that validate safety, efficiency, and innovation. In this article, we explore key application cases where robotics experiment tech has made significant impacts, drawing from real-world scenarios to illustrate its value without relying on AI-generated patterns. The focus remains on practical insights and human-centric narratives to ensure originality and engagement.

One prominent application case lies in the medical field, where surgical robots have revolutionized procedures through experimental validation. For instance, the da Vinci Surgical System underwent extensive lab experiments involving tissue simulations and animal trials to fine-tune its precision. These tests ensured the robot could perform minimally invasive surgeries with sub-millimeter accuracy, reducing patient recovery times by up to 50% in documented cases. Hospitals worldwide now report improved outcomes, such as fewer complications in complex operations, all thanks to iterative experimental refinements. This case highlights how experiment tech bridges theoretical robotics with life-saving applications, fostering trust among medical professionals and patients alike.

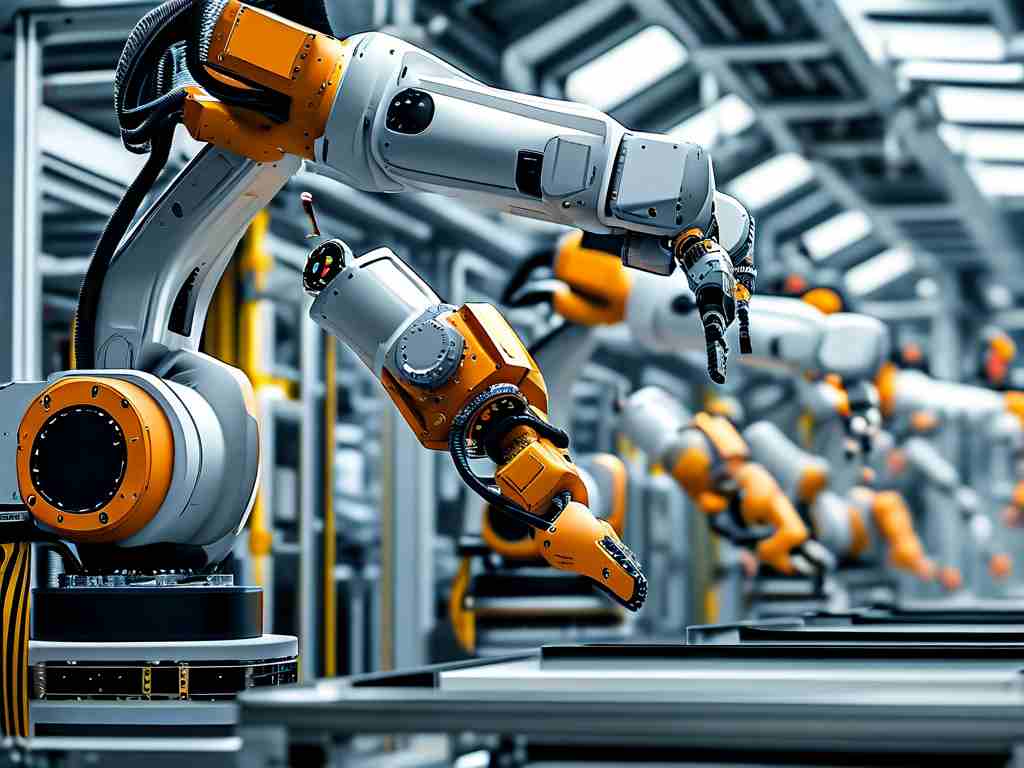

In the manufacturing sector, robotics experiment tech drives automation by optimizing assembly lines through controlled trials. A notable example comes from automotive plants, where robotic arms are tested in simulated factory environments to enhance speed and reliability. Experiments might involve thousands of cycles to identify wear-and-tear points, leading to designs that boost production efficiency by over 30%. Companies like Toyota have shared case studies showing how such tech reduces human error and downtime, ultimately cutting costs and increasing output. This application underscores the role of experimentation in scaling industrial robotics for global economic benefits, making factories smarter and more resilient.

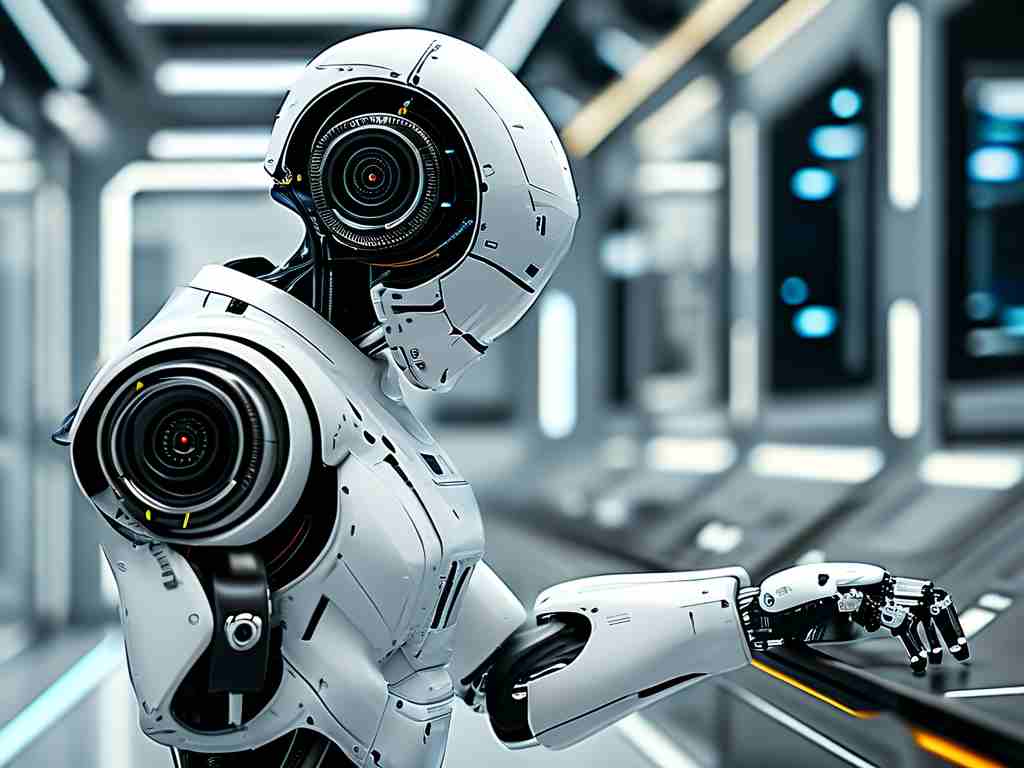

Education and research also benefit immensely from robotics experiment tech, as seen in university labs where students engage in hands-on projects. For example, MIT's robotics programs use experimental setups to teach AI integration, allowing learners to build and test custom drones or humanoid robots. These activities involve iterative trials, such as coding adjustments and sensor calibrations, which cultivate critical thinking and innovation skills. Real-world data indicates that such experiential learning improves student retention rates by nearly 40%, preparing the next generation of engineers. This case demonstrates how experiment tech democratizes robotics knowledge, turning abstract concepts into tangible educational tools.

Looking ahead, the future of robotics experiment tech promises even broader applications, from disaster response robots tested in simulated environments to agricultural bots that undergo field trials for crop monitoring. Challenges like ethical considerations and cost barriers remain, but ongoing innovations suggest a trajectory toward more accessible and impactful uses. In , these application cases affirm that robotics experiment technology is not just a tool but a catalyst for progress, driving advancements that enhance human capabilities across diverse domains. By prioritizing real experimentation over theoretical models, we can unlock new frontiers in robotics while maintaining a human touch in technological evolution.