The whir of servos and the precise movement of articulated limbs signal a quiet revolution: humanoid robots are no longer just pre-programmed automatons; they are evolving into entities capable of acquiring complex technical skills. This leap forward, moving beyond rigid task execution towards genuine learning and adaptation, fundamentally reshapes our understanding of automation's potential. It heralds a future where robots transition from tools to collaborators, capable of mastering intricate procedures once thought exclusive to human expertise.

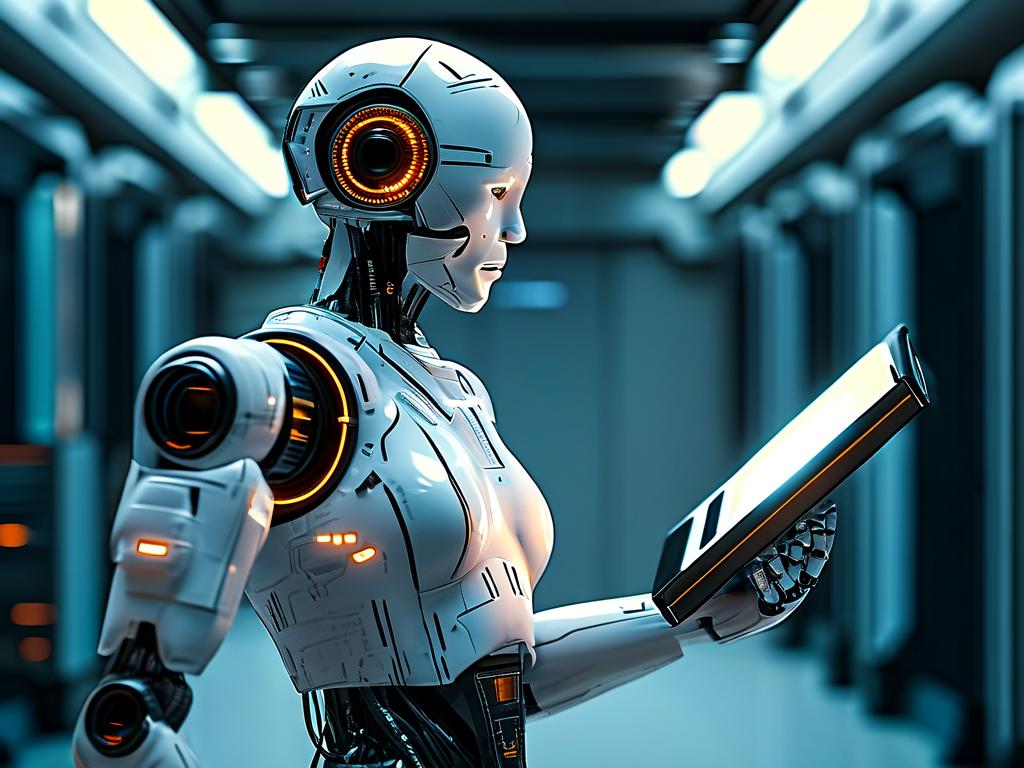

The core of this transformation lies in sophisticated machine learning architectures, particularly deep reinforcement learning and advanced computer vision systems. Unlike traditional robots confined by meticulously coded instructions, modern humanoids learn through observation and practice, much like human apprentices. Equipped with high-resolution cameras and depth sensors, they visually deconstruct tasks performed by human experts. Advanced neural networks then process this visual data, identifying key actions, sequences, and environmental interactions crucial for success. This observational learning phase is often augmented by kinesthetic teaching, where a human physically guides the robot's limbs through the desired motions, providing crucial haptic feedback that refines the robot's internal model of the task.

Simulation plays an indispensable role. Before attempting a complex skill in the physical world, robots rehearse countless times within highly realistic virtual environments. These digital sandboxes allow them to explore different approaches, encounter simulated failures, and iteratively refine their techniques without risk of damage. Reinforcement learning algorithms drive this process; the robot receives digital 'rewards' for successful actions and 'penalties' for failures, gradually converging on the optimal strategy through trial and error. This simulated mastery is then transferred to the real world, where fine-tuning occurs through interaction with actual tools and environments. For instance, a robot learning intricate circuit board soldering might perfect its solder flow control and component placement precision entirely in simulation before handling expensive hardware.

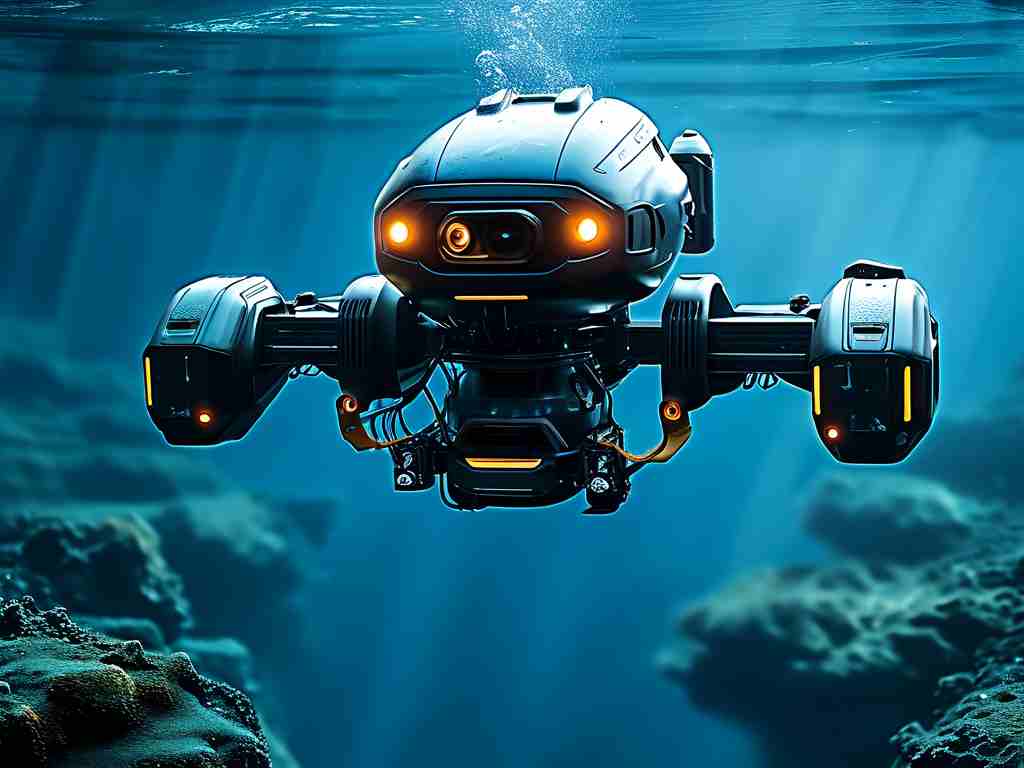

The practical implications are profound across numerous sectors. In advanced manufacturing, imagine humanoids mastering delicate assembly tasks for microelectronics, adapting to component variations in real-time, or performing complex quality control inspections requiring nuanced judgment. Within intricate surgical suites, robots could learn specific techniques from master surgeons, replicating precise suturing or tissue manipulation with superhuman steadiness, potentially assisting in remote procedures. Hazardous environments like nuclear decommissioning or deep-sea repair become safer domains as robots learn complex manipulation skills – operating specialized valves, cutting specific materials, or handling contaminated objects – minimizing human exposure to danger. Even complex equipment maintenance, involving diagnostics and intricate repairs, becomes a domain where these 'digital apprentices' can achieve proficiency.

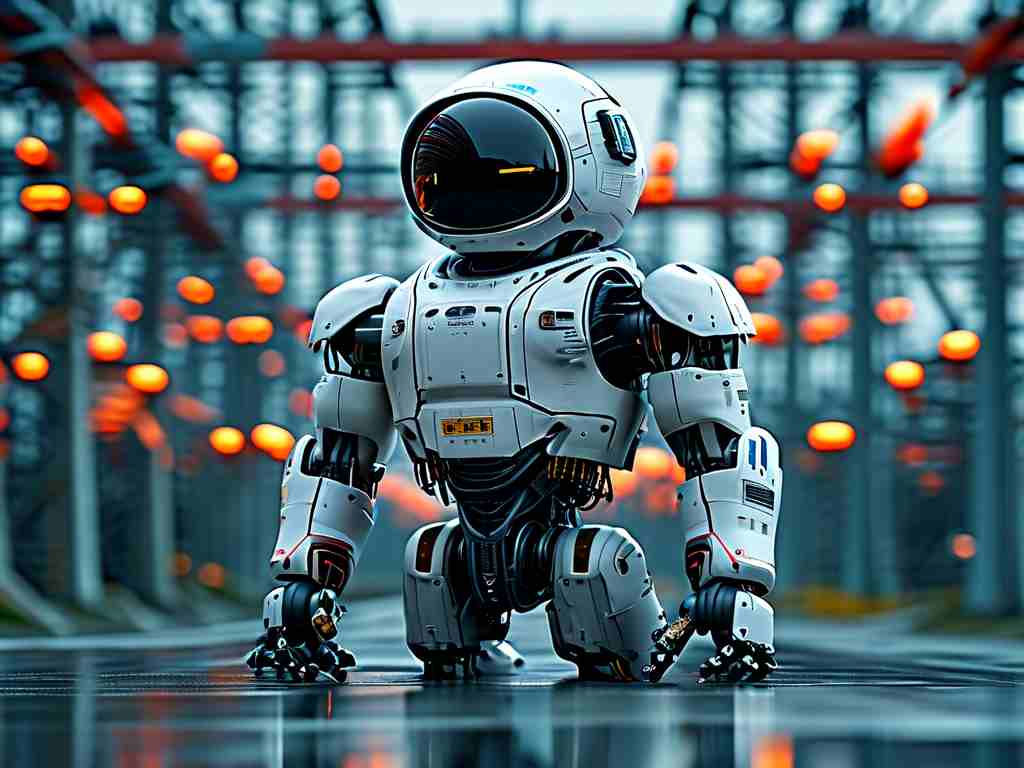

However, significant challenges persist. Mastering the incredible dexterity, fine motor control, and nuanced force application inherent in many technical trades remains an immense hurdle. Current hardware often lacks the subtle tactile feedback and compliance of the human hand. Furthermore, the energy demands of sophisticated, constantly learning humanoids present logistical hurdles for deployment. Perhaps the most critical challenge lies in developing robust safety protocols and fail-safes. Ensuring safe interaction in dynamic, unstructured environments where humans and robots collaborate closely on complex tasks is paramount. Ethical considerations regarding job displacement, the nature of skill acquisition, and establishing clear accountability frameworks also require careful, ongoing societal discourse.

Despite these hurdles, the trajectory is undeniable. Continuous advancements in artificial intelligence, sensor fusion, and actuator design are rapidly closing the gap. Companies like Tesla with Optimus, Boston Dynamics with Atlas, and numerous research labs globally are demonstrating increasingly sophisticated skill acquisition capabilities, from agile locomotion over rough terrain to manipulating unfamiliar objects with adaptive grips. The future envisions a paradigm shift: humanoid robots acting not as replacements, but as capable technical partners. They will handle dangerous, repetitive, or highly precise technical work, freeing human experts to focus on higher-level problem-solving, innovation, and creative oversight. The era where robots learn intricate trades is dawning, promising a fundamental transformation of industry, healthcare, and our relationship with the machines we build.